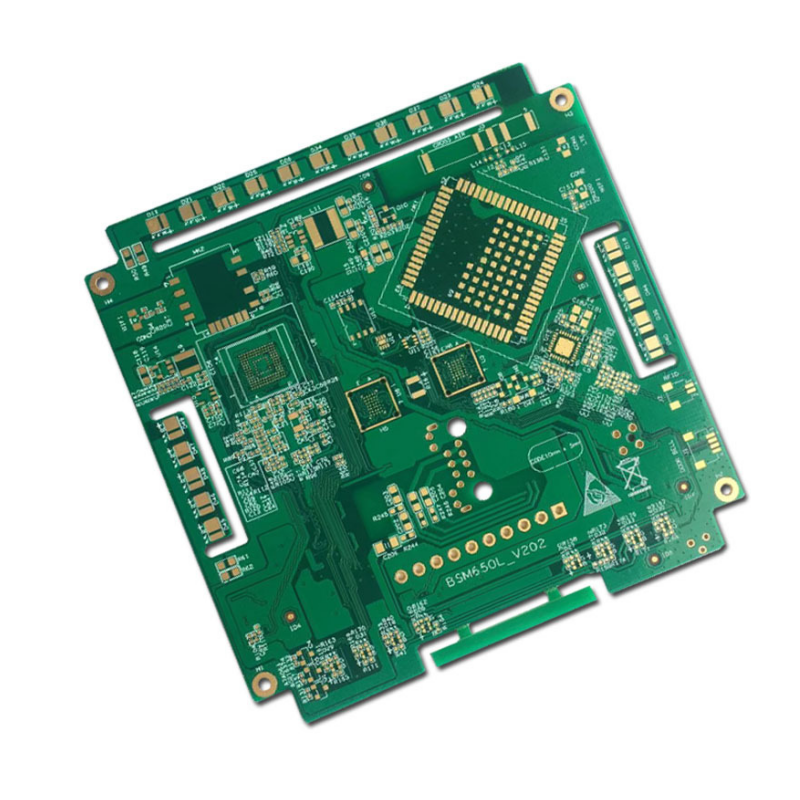

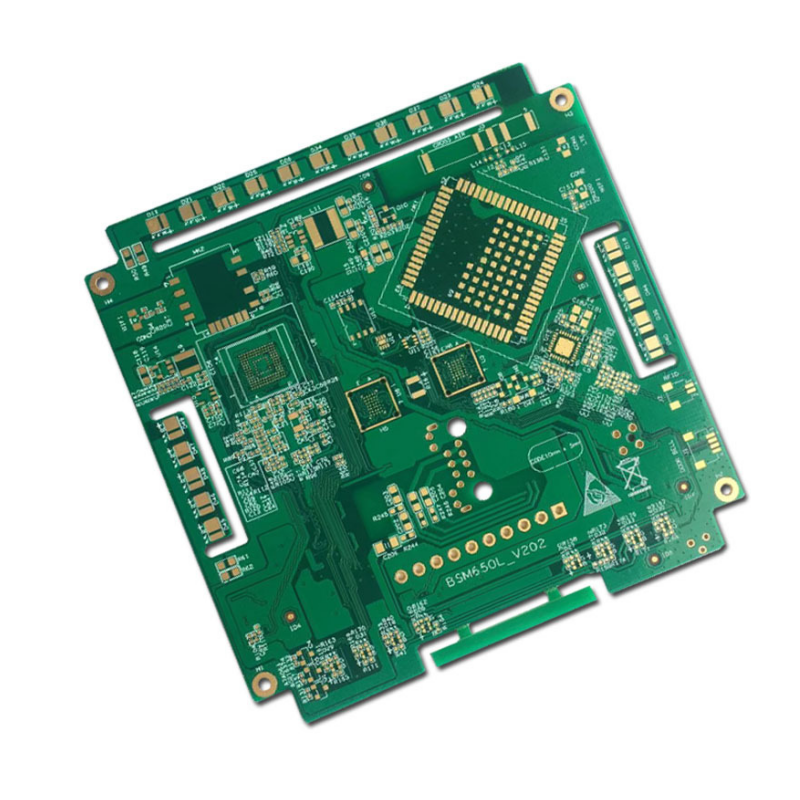

During the assembly process of PCB (Printed Circuit Board), the inspection of DFM (Design for Manufacturing, Design for Manufacturing) design rules is a key link to ensure that the PCB design meets the manufacturing process requirements, improves production efficiency and reduces costs. The following is a detailed summary of the inspection of DFM design rules during the PCB assembly process:

First, the importance of checking DFM design rules

DFM design rule inspection is a process of conducting a comprehensive review of the design documents after the PCB design is completed, aiming to identify and solve problems existing in the design and ensure the manufacturability of the PCB. Through the inspection of DFM design rules, the rework rate in the production process can be reduced, production efficiency and product quality can be improved, and production costs can be lowered.

Second, the main contents of the DFM design rule inspection

Component layout inspection

Component spacing rationality: Check whether the spacing between each component on the PCB is sufficient to avoid solder bridging or short circuits during the soldering process. Generally speaking, for surface mount technology (SMT) components, the pin spacing should be maintained within a reasonable range, such as above 0.5mm.

Layout of large-sized components: Check whether the layout of large-sized components (such as power modules, large electrolytic capacitors, etc.) is reasonable, and avoid placing them at the edge of the PCB or in weak areas near the board edge to enhance the structural stability of the PCB.

Component orientation consistency: Try to design the placement directions of components of the same type to be consistent, which is convenient for machines to install components in one direction during production and improves production efficiency.

Wiring inspection

Line width and line spacing: Check if the line width meets the production process requirements. A line width that is too thin may pose a risk of line breakage during etching, while a line width that is too wide will waste PCB space. At the same time, the line spacing should also be sufficient to prevent short circuits between adjacent lines. Generally speaking, for ordinary FR4 material PCBS, it is more common for the line width and line spacing to be between 0.15mm and 0.2mm.

Signal integrity: Check the length, direction and number of vias of the high-speed signal line to ensure that the signal does not distort during transmission. Signal lines should be as short and straight as possible to avoid excessive bends and vias. For critical high-speed signals, such as clock signals and differential signals, strict impedance matching design should be carried out.

Pad design inspection

Pad size matching: Check whether the size of the pads matches the size of the component pins to avoid loose soldering or pins that cannot be inserted into the pads.

Correct pad shape: Select the appropriate pad shape based on the shape of the component pins and actual needs, such as circular, square, oval, etc.

Solder mask treatment: Check whether solder mask treatment has been applied around the pad to prevent green oil (solder mask layer) from covering the pad and affecting the welding.

Design inspection of holes

Hole diameter and hole spacing: Check whether the diameter and position of the borehole meet the manufacturing requirements to avoid manufacturing difficulties caused by too small a hole diameter or inaccurate position. Meanwhile, check whether the hole spacing meets the requirements to prevent problems such as broken drill bits or short circuits during the drilling process.

Hole ring size: Check if the hole ring size is sufficient to prevent the weak adhesion of the hole plate from causing the solder plate to come off during welding or maintenance.

Inspection of special process requirements

Blind buried vias, HDI, etc. : If the PCB design includes special processes such as blind buried vias, HDI (high-density interconnect), etc., it is necessary to check whether these special processes match the process capabilities of the manufacturer.

Rigid-flexible composite panels: For rigid-flexible composite panels, it is necessary to check whether the special flexible materials and lamination processes required for their production are met.

Testability design check

Test point Settings: Check whether sufficient test points have been set and whether the positions of the test points are convenient for the test equipment to access. For some complex PCBS, it is also necessary to consider whether test interfaces such as boundary scan test (JTAG) need to be designed.

Test point layout: The layout of test points should follow certain rules, such as being evenly distributed on the PCB surface, avoiding being blocked by components, and maintaining a certain distance from adjacent components.

Other examinations

PCB material selection: Check whether the selected PCB material is suitable for the production process and the application environment of the product to avoid PCB deformation, delamination or decline in electrical performance due to material issues during the production process.

Process edges and positioning holes: Check whether the edges of the PCB board have left sufficient width of process edges to facilitate machine clamping and processing of the board during production. Meanwhile, check whether sufficient positioning holes have been designed to ensure the accuracy of component installation and soldering.

Third, the implementation of the DFM design rule inspection

DFM design rule inspection can be carried out through professional DFM inspection software or tools. These software usually predefined a series of design rules, and designers can customize or use the predefined rules to check the manufacturability of the design. During the inspection process, the software will automatically mark all the places that do not comply with the rules. Designers can make modifications and optimizations according to the prompts.

Fourth, Summary

DFM design rule inspection is an indispensable part of the PCB assembly process. Through comprehensive inspection and optimization, the manufacturability of PCB design can be ensured, production efficiency and product quality can be improved, and production costs can be reduced. Therefore, during the PCB design process, full attention should be paid to the implementation of the DFM design rule check.