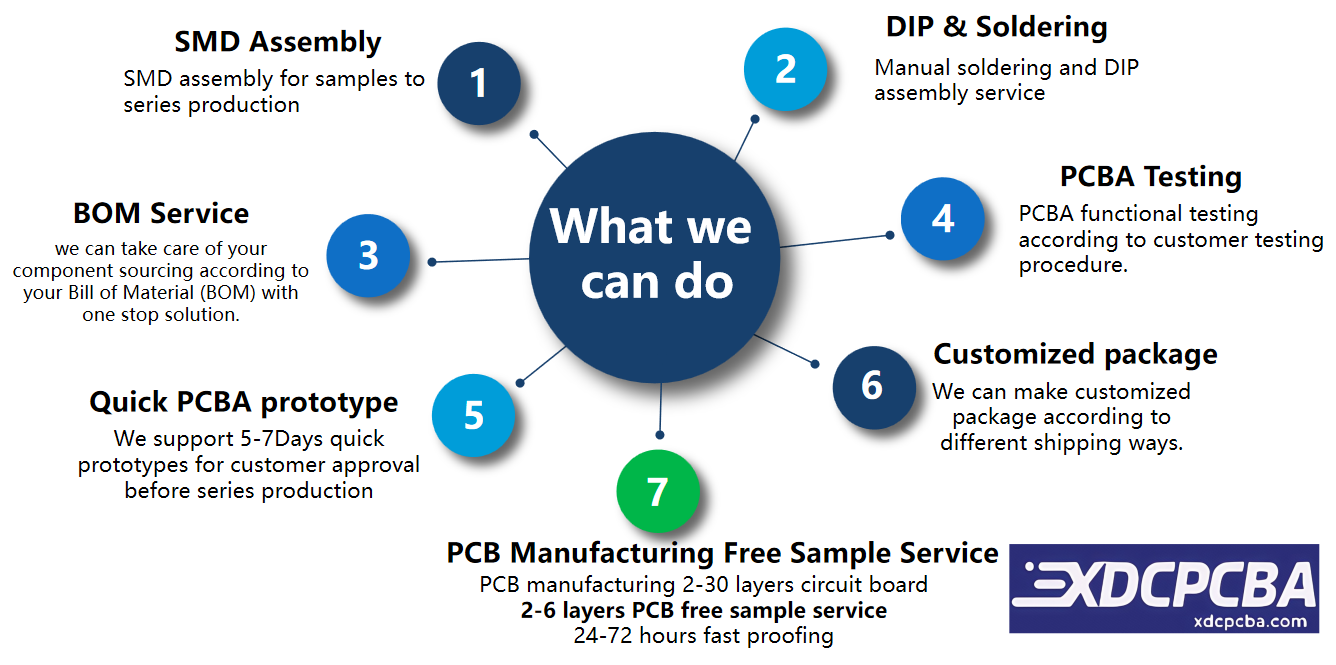

In the field of rigid-flex PCB manufacturing, the 1.0MM 6-layer ENIG (Electroless Nickel Immersion Gold) process showcases unique advantages. XDCPCBA PCB assembly factories, as PCBA processing plants, manufacturers, and electronic contract manufacturers, offer comprehensive services. They possess SMT (Surface Mount Technology) PCB assembly capabilities, are 2 - 30-layer PCB manufacturers, reliable PCB suppliers, and also provide free PCB prototyping services for 2 - 6-layer boards. PCBs find extensive applications in various industries such as automotive electronics, communications, and consumer electronics. These enterprises, with their exquisite craftsmanship and high-quality services, meet the demands of different sectors and drive the electronics industry to new heights.

3MM single-sided copper substrate PCB and new energy electric control LED copper substrate PCB manufacturing have attracted much attention. XDCPCBA PCB manufacturers and PCBA processing plants, PCB assembly manufacturers and electronic contract manufacturers have strong strength. They can provide SMT PCB assembly services, are 2-30 layer PCB manufacturers, and are also reliable PCB suppliers. They also offer 2-6 layer PCB free proofing services. PCB is widely used in industries such as automotive electronics, consumer electronics, communications, and industrial control. These companies rely on superb craftsmanship and high-quality services to meet the different needs of various industries for PCBs and promote the development of the electronics industry.

In the field of electric vehicle controller aluminum substrate and high thermal conductivity LED lamp aluminum substrate manufacturing, the technical requirements are strict. Electric vehicle controllers require efficient heat dissipation aluminum substrates to ensure stable performance, and LED lamp aluminum substrates must achieve good thermal conductivity to improve luminous efficiency.

XDCPCBA PCB assembly factories and other companies, as PCBA processing plants, manufacturers and electronic contract manufacturers, play a key role in the PCB industry chain. They can provide SMT PCB assembly, 2-30 layer PCB manufacturing and other services, as well as 2-6 layer PCB free proofing services. PCB is widely used in many industries, including automobiles, communications, consumer electronics, etc.

Flexible PCB is a circuit board made of flexible substrate (such as polyimide, polyester, etc.) with good bendability and flexibility. It supports high-density wiring and compact design, and is widely evaluated in electronic products that require miniaturization, lightweight and complex wiring, especially in application scenarios that require clearance bending or limited space.

XDCPCBA provides full-process flexible PCB manufacturing and assembly services from design optimization, parts procurement to SMT soldering, BGA packaging, functional testing, etc. We use advanced automation equipment and technology to ensure product loss and high efficiency. Whether it is small-batch prototype production or large-scale production, XDCPCBA can provide flexible customized solutions to meet the different needs of customers.

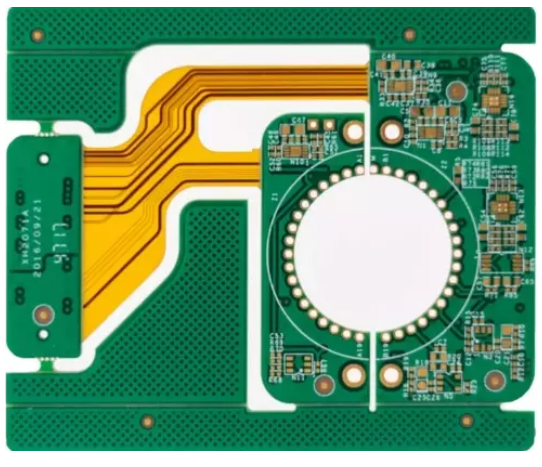

Rigid-flex PCB is a circuit board that combines rigid circuits and flexible circuit boards, usually using connection technology between flexible circuits to provide highly integrated circuit solutions. It has both the stability of rigid circuit boards and the bendability of flexible PCBs, and is widely evaluated for equipment that requires space optimization and performance requirements.

XDCPCBA provides comprehensive manufacturing and assembly services for rigid-flex PCBs. We provide one-stop services from PCB manufacturing, parts procurement, SMT patch, BGA soldering, functional testing, etc. We have a professional technical team to ensure that each rigid-flex PCB meets high-performance requirements, especially in high frequency, high-speed signal transmission, low power consumption and durability.

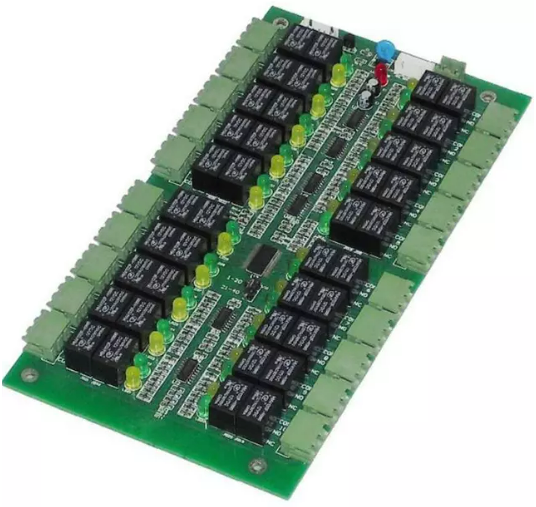

Double-sided PCB Energy Meter PCB Circuit Board is a double-sided circuit board that uses FR4 substrate and is processed by lead-free tinning process to improve the conductivity and wear resistance of the connection points. This PCB is suitable for applications with high requirements for signal stability and durability. It has good electrical performance and corrosion resistance and is widely used in instrumentation and communication fields.

XDCPCBA assembly solutions and customized business:

XDCPCBA provides complete FR4 lead-free tinning double-sided PCB assembly services, including PCB layout design, PCB manufacturing, component procurement, SMT welding, functional testing and quality inspection. We provide customized solutions according to customer needs to ensure that each circuit board meets the requirements of specific applications and has excellent signal transmission performance and reliability.

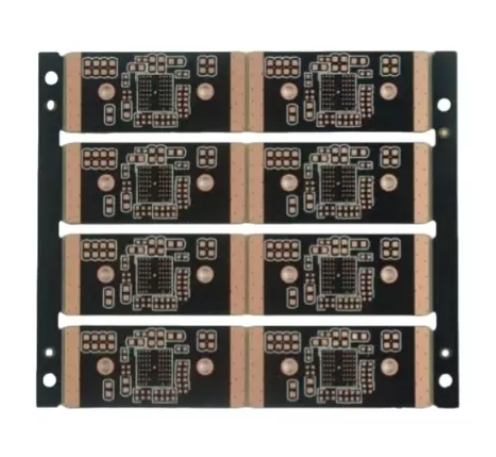

A multi-layer PCB is a circuit board containing multiple conductive layers, which is connected to the outer circuit through the inner circuit, and uses advanced manufacturing technology to achieve high-density integration. It supports complex circuit design and can provide higher performance and smaller space requirements.

XDCPCBA provides complete multi-layer PCB manufacturing and assembly services, including circuit design optimization, component procurement, SMT, BGA welding, functional testing and other full-process services, aiming to ensure high quality, short-cycle delivery, and meet customers' strict requirements in electrical performance, mechanical strength, reliability, etc. We provide flexible customization services to support various complex designs and production needs of different scales.

HDI PCB is a high-density circuit board with advanced manufacturing technology, which supports more layers and sophisticated circuit design. It uses micro-via and blind hole technology to enable miniaturization and high-density integration of circuit boards while maintaining high performance, which is suitable for modern electronic devices that require high transmission speed and low power consumption.

XDCPCBA provides a full range of manufacturing and assembly services for HDI PCB, including all aspects from PCB design optimization, component procurement to SMT welding, functional testing, etc. We provide customers with flexible customization solutions to ensure that each circuit board meets application requirements, especially in providing solutions for high-frequency signals, low power consumption and compact design. XDCPCBA supports large-scale production and guarantees high-quality delivery.

XDCPCBA is a world-leading metal substrate manufacturer, focusing on the high-precision R&D and production of aluminum PCB and copper PCB, providing efficient thermal conductivity solutions for high heat dissipation scenarios such as LED lighting, power modules, and automotive electronics. The company is equipped with advanced processes such as vacuum pressing, laser grooving, and lead-free tin spraying, supporting aluminum layer thickness of 1-3mm, copper layer thickness of 1-10OZ (35-350μm), and thermal resistance as low as 0.3℃・in²/W, meeting the needs of different power devices.

XDCPCBA, as a professional supplier of metal substrate solutions, focuses on the research and production of copper clad laminates (CCL) and aluminum substrates, combined with high-precision PCB assembly capabilities, providing one-stop services for high-power, heat sensitive electronic devices. The company is equipped with advanced processes such as vacuum pressing, laser slotting, and lead-free tin spraying, supporting copper layer thickness of 1-10OZ (35-350 μ m) and thermal resistance as low as 0.3 ℃ · in ²/W, meeting high heat dissipation requirements in LED lighting, power modules, automotive electronics, and other scenarios.

We offer IMS PCB manufacturing, providing cutting-edge solutions for industries such as automotive, LED lighting, renewable energy, and industrial automation. Our IMS PCBs feature a metal core (typically aluminum or copper) that effectively dissipates heat, ensuring reliability and longevity in even the most demanding environments.

With advanced manufacturing techniques, rigorous quality testing, and a commitment to customization, we deliver high-quality IMS PCBs tailored to your specific needs. Whether you’re designing high-power LED systems, automotive electronics, or industrial equipment, our IMS PCBs offer unmatched thermal conductivity, electrical insulation, and durability.

XDCPCBA PCBA manufacturer, as a leader in the field of elevator controller PCBA assembly, integrates PCB assembly factory and PCB service, and focuses on providing high-quality elevator controller PCB assembly solutions. We are not only proficient in elevator control system PCBA processing, but also proficient in the refined manufacturing of elevator control motherboard PCBA. As a professional PCB manufacturer, we have 2-30 layers of PCB manufacturing. As a PCB assembly supplier and PCBA supplier, we provide one-stop electronic contract manufacturing and electronic manufacturing services to Chinese and global customers. It is particularly worth mentioning that we provide free sample services of 2-6 layers of PCB to new customers, and recognize our professional strength and service with practical action exercises. Choose XDCPCBA PCBA manufacturer to make your controller PCBA assembly project more efficient.

XDCPCBA PCBA manufacturer provides elevator controller motherboard PCBA processing services, with a complete PCB assembly factory and a full range of PCB services. We focus on the assembly of elevator controller PCBs and the PCBA processing of elevator control systems, and are committed to meeting customers' needs for high-quality elevator control motherboards. As a PCB manufacturer, we provide 2-30-layer PCB manufacturing services and are a well-known PCB assembly supplier and PCBA supplier in the industry. As China's leading PCBA processing factory, we provide one-stop electronic contract manufacturing and electronic manufacturing services, and especially provide free sample services for 2-6-layer PCBs for new customers. Choosing us means choosing professional, efficient and reliable elevator controller motherboard PCBA processing services.

XDCPCBA launches standard POE powered switch module PCBA assembly, which integrates safety, stability and innovation, and is specially designed for network equipment. As an efficient and professional PCBA manufacturer, we provide a full range of services from 2-30 layer PCB manufacturing to fine PCB assembly, head routers, switches and other core network equipment. Our PCB assembly factory adopts advanced technology to ensure that every PCBA meets the highest standards. In addition, we also specially provide 2-6 layer PCB free sampling service to provide customers with fast verification of design. XDCPCBA, with excellent quality and professional service, leads the new trend of network equipment manufacturing.

XDCPCBA launches the standard POE power supply switch module PCB assembly, which combines high efficiency and stability, and is designed to meet the needs of modern network equipment. As a professional PCB manufacturer and PCBA manufacturer, we provide one-stop services from 2-30 layers of PCB manufacturing to PCB assembly. Whether it is router PCB assembly, router PCBA processing, switch PCBA processing, switch PCB assembly, we have successfully completed it. In addition, we also provide 2-6 layers of PCB free sampling service, customer service quickly verify the design. XDCPCBA, the POE connection switch module PCB assembly expert at your service.

XDCPCBA, as a leader in the field of router switch PCB assembly, we integrate PCB manufacturing, assembly and processing to provide customers with a full range of electronic manufacturing services. As a professional PCB manufacturer, we have 2-30 layers of PCB manufacturing capabilities to ensure excellent product performance. At the same time, we focus on the PC B structure and PCBA processing of routers and switches, and have won the trust of customers with exquisite craftsmanship and strict quality control. In addition, we also provide 2-6 layers of PCB free sample service to help customers quickly verify the design and the entire product launch cycle. XDCPCBA, the preferred partner for router switch PCB assembly.

XDCPCBA is a professional industrial switch module PCBA assembly service provider, integrating PCB manufacturing, PCB assembly and PCBA processing, with 2-30 layers of PCB manufacturing capabilities. It is not only a PCB manufacturer and PCB assembly supplier, but also a well-known PCBA processing plant and electronic contract manufacturer in China. We focus on providing high-quality PCBA assembly services for routers and switches, and are committed to meeting the needs of customers. In addition, we also provide 2-6 layers of PCB free sample services to help customers quickly verify the design and accelerate product launch. XDCPCBA, please be your industrial switch module PCBA assembly expert.

XDCPCBA, as a leader in industrial Gigabit switch module PCB assembly services, we provide comprehensive PCB and PCBA solutions. Relying on professional PCB assembly factories and advanced production equipment, we are good at 2-30 layer PCB manufacturing, as well as PCB assembly and PCBA processing for routers and switches. As a PCB manufacturer, PCB assembly supplier and PCBA supplier, we are committed to providing high-quality electronic manufacturing services to Chinese and global customers. In particular, we provide 2-6 layer PCB free sample services to help customers quickly verify designs and accelerate product launch. XDCPCBA, your trusted electronic contract manufacturer.

As a leading manufacturer of 4G LTE wireless router PCB assembly, XDCPCBA provides one-stop services from PCB design, manufacturing to assembly. We have a professional PCB assembly factory and PCB service team that can manufacture 2-30 layers of PCB to meet various complex design requirements. As a PCB manufacturer and PCBA supplier, we provide high-quality router PCB assembly and PCBA processing services to ensure the excellent performance and stability of 4G LTE wireless routers. In addition, we also provide 2-6 layers of PCB free sample services to help customers quickly verify the design and advance the project. As an electronic contract manufacturer and electronic manufacturing service, XDCPCBA is committed to providing high-quality 4G LTE wireless router PCB assembly solutions to customers in China and even around the world.

As a professional UAV flight control and PCBA manufacturer, XDCPCBA provides comprehensive UAV PCB processing and PCBA manufacturing services. As a PCB manufacturer, the company has the ability to manufacture 2-30 layers of PCB, and specially launched a 2-6 layer PCB free sample service to meet customer visual needs. As an electronic contract manufacturer and a booming electronic manufacturing service, XDCPCBA provides high-quality UAV PCBA solutions to global customers with its rich experience and advanced technology. Whether it is the precise control of the UAV flight control system or the extreme flight of the cross-country drone, XDCPCBA can provide customized services to help customers achieve greater breakthroughs in the field of aviation technology.

The drone motherboard PCB is a high-performance, highly integrated multi-layer circuit board, mainly used to connect various electronic modules of drones, such as flight control, power management, GPS, sensors, etc. The PCB design requires anti-interference, high temperature resistance, lightweight and other characteristics to ensure stable signal transmission and system operation in complex flight environments.

XDCPCBA assembly solutions and customization services:

XDCPCBA provides a full set of assembly solutions for drone motherboard PCBs, including component procurement, SMT welding, manual welding, functional testing and debugging. We provide customized services to meet customers' needs for flight stability, anti-interference, low power consumption, etc. Whether it is small batch or large-scale production, XDCPCBA can provide precise assembly and high quality assurance to ensure that each motherboard meets technical specifications and reliability requirements.

XDCPCBA provides manufacturing and assembly services for Stretchable Rollable Display PCB. Our factory has 10 fully automatic SMT production lines and rich experience in component procurement, which can save customers time and certain economic costs. Our one-stop manufacturing and assembly service supports solutions that customers need at any stage.

XDCPCBA, as the leader of PCBA processing for Wuling automotive window lifters, is a comprehensive service provider integrating PCB manufacturing, PCB assembly and PCBA processing. As a leader of China PCBA manufacturers, China PCBA manufacturers and China PCBA suppliers, we have advanced production equipment and technical teams, capable of producing PCBs from 2 to 30 layers, and specially provide 2-6 layers PCB free sample service. Combined with comprehensive Electronic Manufacturing Services (EMS), XDCPCBA provides one-stop, efficient PCBA processing solutions for Wuling automotive window lifters as a PCBA manufacturer and supplier, as well as a PCB assembly supplier, PCB assembly factory and PCB assembly manufacturer, ensuring excellent product performance and reliable quality.

XDCPCBA, as a well-known PCB manufacturer and PCBA processing manufacturer in the industry, we focus on providing customized PCBA processing services for Tesla car lifting systems. As a leader in China's PCBA manufacturers, China's PCBA manufacturers and China's PCBA suppliers, we have a complete PCB assembly factory that can produce PCBs from 2 to 30 layers, and specially provide 2-6 layers of PCB free sample services. Combined with comprehensive Electronic Manufacturing Services (EMS), XDCPCBA is committed to meeting the high-quality PCBA processing needs of Tesla's car lifting systems.

XDCPCBA, a leader in the PCB manufacturing industry, a professional PCB production factory and a leader in PCBA processing, we are proud to launch car fast wireless charging as a PCBA charging module. As a representative of Chinese PCBA manufacturers, a preferred brand of Chinese PCBA manufacturers and Chinese PCBA suppliers, we are committed to providing customers with one-stop electronic manufacturing services. As a professional manufacturer of 2-30 layers of PCB, we not only meet customers' needs for circuit board layers, precision, performance and other aspects, but also feature 2-6 layers of PCB free sample services to help customers quickly verify the design and the entire cycle of research and development. XDCPCBA, with excellent quality and innovative technology, creates a solid hardware foundation for your car's car fast charging charging module.

XDCPCBA, as a leading PCB manufacturer and PCBA processing factory, we focus on providing high-quality anti-pinch motor PCBA assembly services for the automotive industry. As a leader among Chinese PCBA manufacturers, we not only have advanced production equipment and technology, but also have a group of experienced engineers and technicians. As a trusted Chinese PCBA manufacturer and supplier, we are committed to meeting the diverse needs of customers, especially for the manufacture of 2-30 layers of PCB, we have excellent production capacity and quality assurance. In addition, in order to give back to our customers, we specially provide free sample services for 2-6 layers of PCB, so that every customer can experience our professionalism and sincerity. Choosing XDCPCBA means choosing trust and quality.

XDCPCBA, as the industry's leading PCB manufacturer and PCBA processing manufacturer, focuses on providing excellent PCBA processing services for the smart door lock field. As a leader among Chinese PCBA manufacturers, XDCPCBA not only has advanced PCB assembly factories and superb SMT assembly processing technology, but is also the preferred choice for 2-30 layer PCB manufacturers. We are committed to providing customers with one-stop electronic manufacturing services from design to production, and especially provide 2-6 layer PCB free sample services to meet customers' diverse R&D and testing needs. As a Chinese PCBA manufacturer and supplier, XDCPCBA has won the trust and praise of customers with high-quality and efficient services, and is your ideal choice for smart door lock PCBA processing.

XDCPCBA, as a well-known PCB manufacturer and PCBA processing manufacturer in the industry, focuses on providing high-quality PCB assembly services for the smart door lock field. As a leader among Chinese PCBA manufacturers, XDCPCBA not only has advanced PCB assembly factories and superb SMT assembly processing technology, but is also the preferred choice of 2-30 layer PCB manufacturers. We are committed to providing customers with one-stop electronic manufacturing services from design to production, and especially provide 2-6 layer PCB free sample services to meet customers' diverse R&D and testing needs. As a reliable Chinese PCBA manufacturer and supplier, XDCPCBA has won the trust and praise of customers with high-quality and efficient services.

XDCPCBA, as a well-known PCB manufacturer and PCBA processing factory, focuses on providing high-quality PCB assembly services for access control systems. As a Chinese PCBA manufacturer, manufacturer and supplier, we have comprehensive electronic manufacturing service capabilities, including PCB design, manufacturing, SMT assembly processing and other one-stop services. XDCPCBA's PCB assembly factory is equipped with advanced production equipment, which can meet the manufacturing needs of 2-30 layers of PCB. In order to help customers better verify the design, we also provide 2-6 layers of PCB free sample service. Choosing XDCPCBA means choosing the professionalism and trust of PCB for access control systems.

XDCPCBA, as a leader of Chinese PCBA manufacturers, focuses on Internet of Things (IoT) PCBA processing services. As a PCB manufacturer and PCBA processing manufacturer, we have a modern PCB assembly factory, providing one-stop electronic manufacturing services from PCB design, manufacturing to SMT assembly processing. As a 2-30 layer PCB manufacturer, we are good at handling PCB requirements of various complexities of IoT devices, and provide 2-6 layer PCB free sample services to help customers quickly verify designs and accelerate product launch. As a Chinese PCBA manufacturer and supplier, XDCPCBA has won the trust and praise of customers in the field of IoT with high quality, high efficiency and reliable services, and is your preferred partner for IoT PCBA processing.

XDCPCBA, an outstanding representative of China's PCBA manufacturers, focuses on PCB assembly services for the Internet of Things (IoT). As a PCB manufacturer and PCBA processing manufacturer, we have a modern PCB assembly factory, providing one-stop electronic manufacturing services from PCB design, manufacturing to SMT assembly processing. As a 2-30 layer PCB manufacturer, we are able to meet the needs of IoT devices for PCB boards, and provide 2-6 layer PCB free sample services to help customers quickly verify the design. XDCPCBA, as a Chinese PCBA manufacturer and supplier, has won the reputation and regret of customers in the IoT field with high quality, high efficiency and reliable services, and is your ideal choice for IoT PCB.

XDCPCBA, as a leading Chinese PCBA manufacturer, focuses on PCB assembly services for access controllers. As a PCB manufacturer and PCBA processing manufacturer, we have an advanced PCB assembly factory, providing one-stop services from PCB design, manufacturing to SMT assembly processing. As a 2-30 layer PCB manufacturer, we can meet the various needs of access controllers for PCB boards, and provide 2-6 layer PCB free sample services to help customers quickly verify the design. XDCPCBA, as a Chinese PCBA manufacturer and supplier, has won the trust and reputation of a large number of customers with high quality, high efficiency and reliable services, and is your ideal choice for access controller PCB.

XDCPCBA, as a leader of Chinese PCBA manufacturers, focuses on providing high-quality PCBA processing services for access control systems. As a PCB manufacturer and PCBA processing manufacturer, we have advanced PCB assembly factories and superb SMT assembly processing technology. As a 2-30 layer PCB manufacturer, we can meet the diverse PCB needs of access control systems, and provide 2-6 layer PCB free sample services to help customers quickly verify the design. XDCPCBA, as a Chinese PCBA manufacturer and supplier, with excellent quality, efficient service and flexible cooperation mode, has become your ideal choice for PCBA processing of access control systems, adding reliable protection to your access control system.

XDCPCBA, as a leading PCB manufacturer and PCBA processing manufacturer today, focuses on providing excellent PCBA processing services for the smart lock field. As a leader among Chinese PCBA manufacturers, we have advanced PCB assembly factories and high-quality SMT assembly processing technology. As a 2-30 layer PCB manufacturer, we can meet customers' needs for circuit board layers, precision and performance. In addition, XDCPCBA also provides 2-6 layer PCB free sample services to help customers quickly verify the design and complete the product launch cycle. Choosing XDCPCBA means choosing high-quality, efficient electronic manufacturing services and reliable PCBA processing solutions.