Printed Circuit Board Assembly (PCB Assembly) is at the heart of every modern electronic device. From consumer electronics and industrial equipment to automotive systems and medical instruments, PCB Assembly determines the overall reliability and performance of a product. As devices become smaller, faster, and more complex, manufacturers require highly efficient assembly processes that ensure both functionality and durability.

Two of the most widely used technologies in PCB Assembly are Surface Mount Technology (SMT) and Through-Hole Technology (THT). While both methods are essential for mounting electronic components onto a PCB, they serve different purposes and complement each other in many applications. SMT is well known for its ability to handle small, lightweight components with high precision and automation, making it ideal for compact and high-density circuit designs. In contrast, Through-Hole Technology is preferred for components that require strong mechanical support, such as connectors, transformers, or high-power devices.

Overview of SMT and Through-Hole Technologies

Surface Mount Technology (SMT)

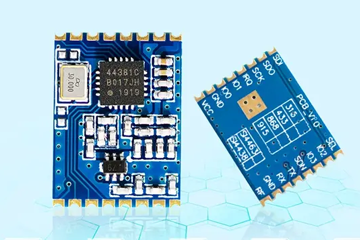

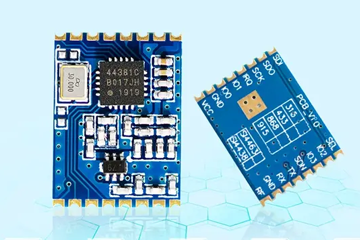

Surface Mount Technology is the most widely used method in modern PCB Assembly. In SMT, electronic components—known as Surface Mount Devices (SMDs)—are mounted directly onto the surface of the PCB rather than being inserted into drilled holes. This approach allows for high-density component placement, which is essential for compact and lightweight electronic products.

Key features of SMT include:

High-Density Mounting: SMT enables the placement of multiple components on both sides of the PCB, allowing for more complex and compact circuit designs.

Automation and Efficiency: SMT relies on automated pick-and-place machines, solder paste printers, and reflow ovens, which significantly increase production speed and consistency.

Compatibility with Miniaturized Components: With the ongoing trend toward smaller devices, SMT is ideal for handling tiny components such as resistors, capacitors, and integrated circuits.

Because of these advantages, SMT is widely applied in industries like consumer electronics, IoT devices, automotive control systems, and telecommunications equipment, where space efficiency and production speed are critical.

Through-Hole Technology (THT)

Through-Hole Technology is a traditional yet indispensable PCB assembly method where component leads are inserted into drilled holes on the PCB and soldered on the opposite side. Although it is less automated compared to SMT, THT provides strong mechanical bonding, making it ideal for components subjected to mechanical stress or high power loads.

Key features of THT include:

Superior Mechanical Strength: Components such as connectors, switches, relays, and large capacitors benefit from the strong bond provided by through-hole soldering.

High Reliability for Power and Stress-Bearing Parts: THT is preferred for parts that need to withstand environmental stress, vibration, or repeated mechanical forces.

Best Choice for Certain Specialty Components: Some components, especially those with complex or large lead structures, are still manufactured exclusively for through-hole mounting.

In many applications—such as industrial machinery, automotive electronics, and aerospace systems—THT remains essential for ensuring product reliability in challenging environments.

By combining SMT’s high-precision, high-speed assembly capabilities with THT’s robust mechanical and electrical connections, manufacturers can achieve the best of both worlds, producing PCBs that are both compact and durable. Shenzhen Xindachang Technology Co., Ltd. leverages fully automated SMT lines and advanced wave soldering equipment to provide customers with seamless mixed-technology PCB Assembly solutions.

Why Combining SMT and Through-Hole Is Necessary

Modern electronic products are becoming more complex and multifunctional, requiring a combination of lightweight, high-density components and large, mechanically strong parts. Relying solely on SMT or THT is often not feasible. For example:

Automotive Control Units (ECUs): Require SMT for microcontrollers and sensors, but rely on THT for power connectors and relays that withstand vibration.

Industrial Control Boards: Need SMT for precision electronics while using THT for high-power components like transformers or terminal blocks.

Medical Devices and Aerospace Systems: Require highly reliable assembly processes that combine both techniques to ensure safety and long-term durability.

By integrating both methods, manufacturers can maximize the strengths of each technology, creating PCBs that are compact, efficient, and durable.

How They Work Together in PCB Assembly

In many modern electronic products, relying solely on SMT or Through-Hole Technology is not enough. Complex devices—such as automotive control units, industrial automation systems, and power electronics—often require a mix of both lightweight SMD components and larger, mechanically strong through-hole parts. This is where mixed-technology PCB assembly becomes essential.

Typical Mixed Assembly Process

PCB Preparation and SMT Component Placement

The process begins with the preparation of the PCB, which may include stencil printing of solder paste on designated pads. Using high-speed pick-and-place machines, Surface Mount Devices (SMDs) such as resistors, capacitors, integrated circuits, and sensors are precisely mounted onto the PCB. SMT offers the advantage of placing components with high accuracy and speed, even on both sides of the board for complex multilayer designs.

Reflow Soldering for SMT Components

After placement, the PCB goes through a reflow oven, where the solder paste melts and forms strong electrical and mechanical bonds. This step ensures that all SMT components are securely attached to the board. With precise temperature control, reflow soldering maintains solder joint integrity, which is critical for ensuring long-term reliability.

Through-Hole Component Insertion

Once the SMT process is completed, the PCB moves to the through-hole assembly stage. Larger components—such as connectors, transformers, relays, and certain power modules—are inserted into pre-drilled holes on the PCB. These components often have long leads and require additional mechanical strength to handle vibration, frequent plugging/unplugging, or high current loads.

Wave Soldering or Selective Soldering

After insertion, the through-hole components are soldered using wave soldering (DIP) or selective soldering equipment. In wave soldering, the entire underside of the board is passed over a wave of molten solder, allowing all the leads to be soldered simultaneously. For boards with sensitive SMT parts, selective soldering is used to precisely solder only the through-hole components without affecting other areas of the PCB.

Final Inspection and Quality Testing

Once all components are assembled, the PCB undergoes rigorous inspection and testing. Automated Optical Inspection (AOI) checks for solder defects or misplaced components. X-ray inspection is used for components such as BGAs, where solder joints are hidden under the package. Finally, functional testing ensures that the assembled PCB performs as intended under real-world conditions.

Benefits of Combining SMT and Through-Hole

Using both SMT and Through-Hole technologies together in PCB Assembly provides manufacturers with a range of advantages that neither process can achieve alone. This combined approach enhances both electrical performance and mechanical reliability, making it ideal for complex and high-demand applications.

1. Greater Electrical and Mechanical Reliability

SMT ensures precise placement of small and lightweight components, which improves signal integrity and allows for high-speed circuit performance.

Through-Hole offers strong mechanical bonding, making it suitable for components exposed to vibration, high currents, or repeated physical stress.

By combining the two methods, PCBs can achieve excellent durability and long-term stability, especially in automotive, aerospace, and industrial control applications where reliability is critical.

2. Increased Design Flexibility and Functional Integration

Designers can leverage SMT for compact, high-density circuits while reserving through-hole mounting for larger, heavy-duty components.

This flexibility allows engineers to create boards that balance miniaturization with structural robustness, supporting more complex and multifunctional designs.

Mixed assembly also makes it easier to integrate both analog and digital circuits, power modules, and connectors on a single PCB.

3. Cost and Production Efficiency

Combining both processes in one production line reduces the need for separate assemblies, lowering overall manufacturing costs.

SMT speeds up high-volume production, while Through-Hole ensures the reliability of components that cannot be surface-mounted.

4. Versatility for Multiple Applications

Many industries—such as automotive electronics, medical devices, industrial machinery, and IoT devices—require PCBs that support both small, high-speed components and larger power-handling parts.

Mixed assembly enables manufacturers to meet diverse application requirements without compromising on quality or performance.

Conclusion

Shenzhen Xindachang Technology Co., Ltd. (XDCPCBA) is a trusted one-stop partner for high-quality PCB manufacturing and assembly. With advanced SMT lines, automated through-hole soldering, strict quality control, and professional engineering support, the company delivers reliable solutions for industries such as automotive, medical, IoT, and industrial electronics.

By combining the precision of SMT with the durability of through-hole technology, XDCPCBA ensures every project meets global standards for performance and reliability. Whether you need prototypes, small-batch production, or large-scale manufacturing, their team provides end-to-end services—from PCB fabrication and component sourcing to final assembly and testing.