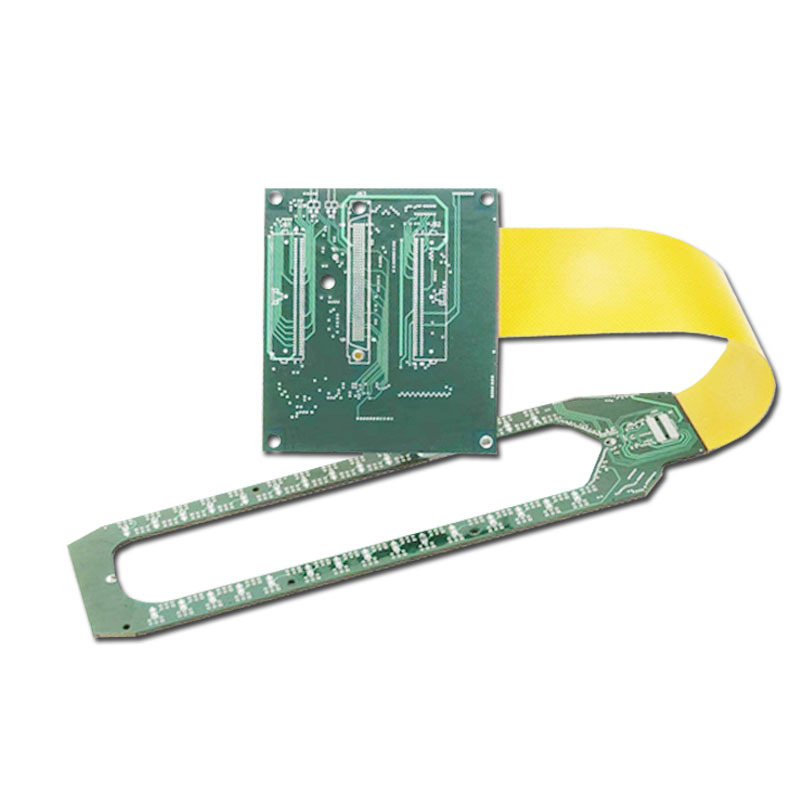

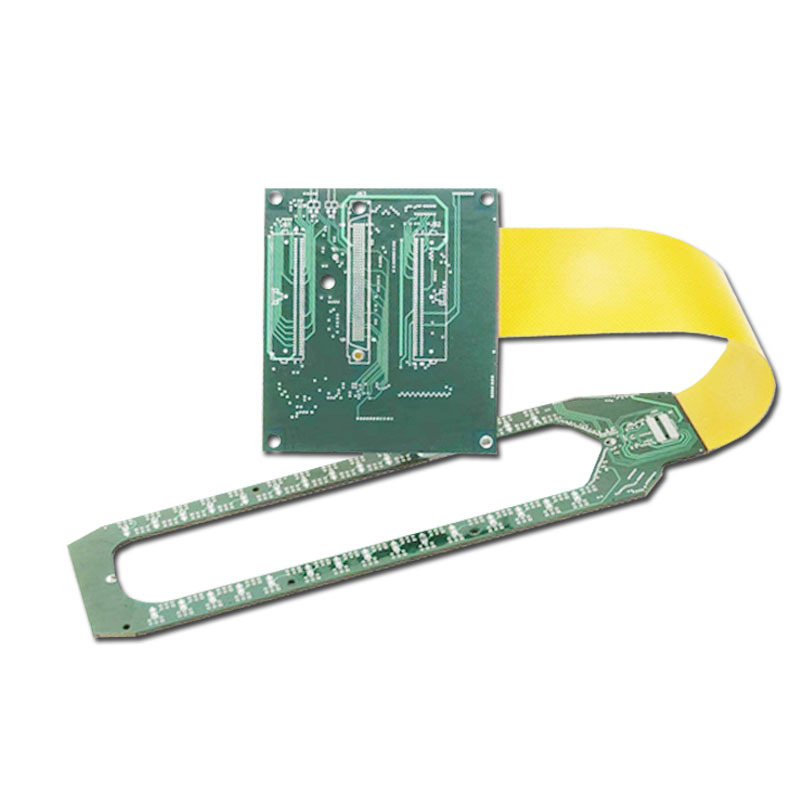

In the realm of electronics manufacturing, the 1.0MM 6-layer ENIG process in rigid-flex PCB manufacturing stands out as a significant highlight. This process combines the stability of rigid PCBs with the flexibility of flexible PCBs, while the ENIG treatment enhances the PCB's conductivity and corrosion resistance, making it perform exceptionally well in numerous application scenarios. XDCPCBA PCB assembly factories, as prominent players in the PCB industry, integrate multiple roles.

They are equipped with advanced production equipment and professional technical teams, with extensive experience in SMT PCB assembly, ensuring high precision and quality in the assembly process. As 2 - 30-layer PCB manufacturers, they can meet the diverse needs of customers regarding the number of layers and complexity of PCBs. As PCB suppliers, they offer a wide range of products to cater to the market's diversified demands. The free PCB prototyping service for 2 - 6-layer boards further reduces customers' R&D costs and risks, accelerating product launch.

The application fields of PCBs are extremely extensive. In the automotive electronics sector, from engine control systems to intelligent driving assistance systems, rigid-flex PCBs are indispensable for stable signal transmission and precise equipment control. In the communications industry, 5G base stations and satellite communication devices require high-performance PCBs to support high-speed data transmission. In the consumer electronics sector, smartphones and wearable devices, pursuing thinness and high integration, find rigid-flex PCBs to be an ideal choice. In the industrial control sector, automated production lines and industrial robots rely on PCBs for precise control and efficient operation. In the medical electronics sector, medical imaging equipment and implantable medical devices have extremely high requirements for the reliability and biocompatibility of PCBs. In the aerospace sector, PCBs need to meet special requirements such as high-temperature resistance and radiation resistance. Facing these challenges, XDCPCBA PCB assembly factories and other enterprises need to continuously innovate and improve their technological levels to meet the stringent requirements of various industries for PCBs.