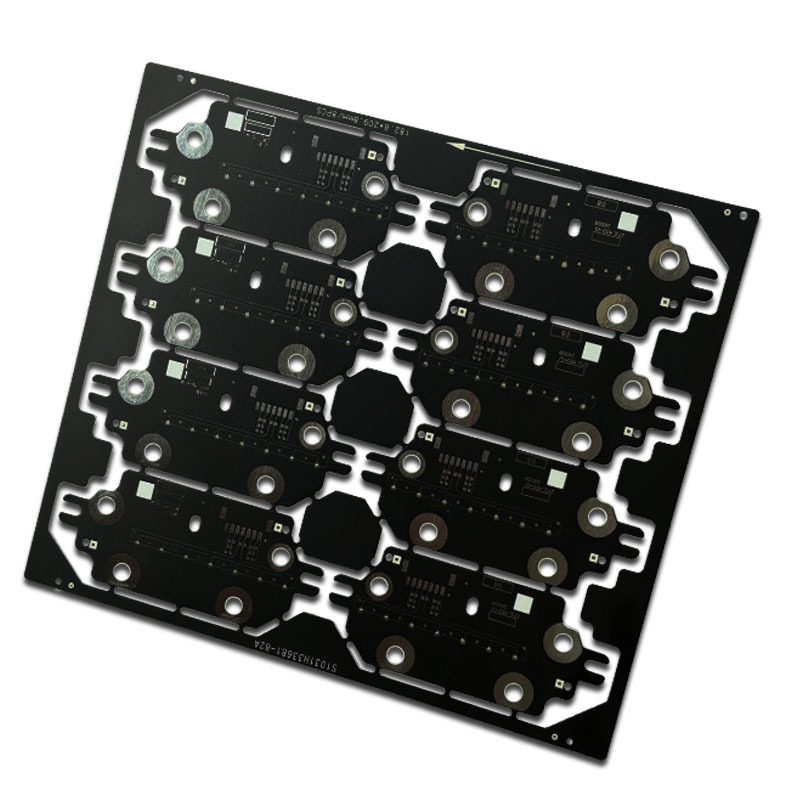

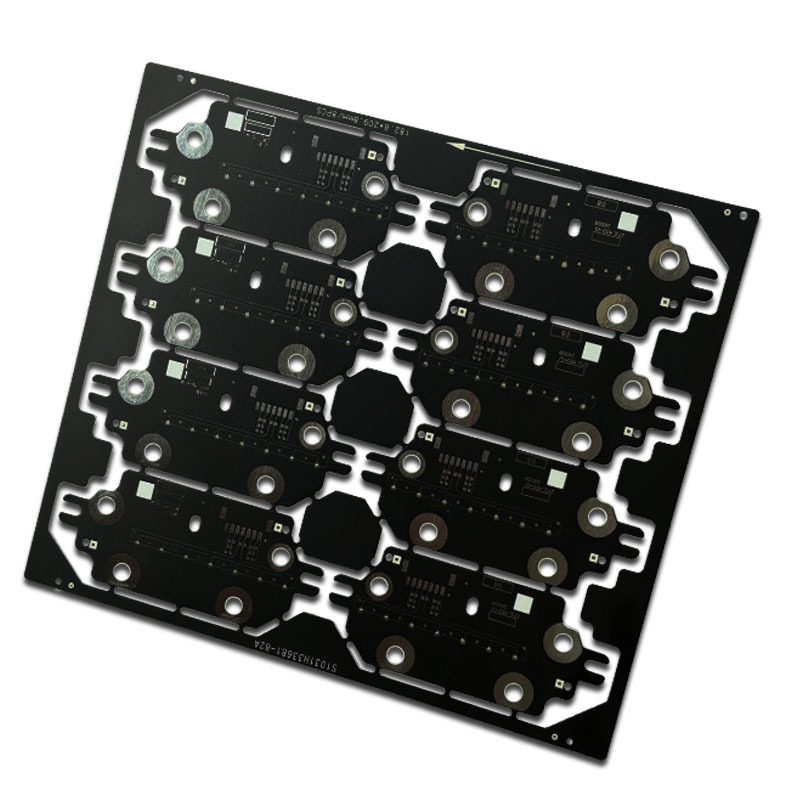

The field of high thermal conductivity aluminum substrates for electric vehicle controllers and aluminum substrates for LED lamps is showing great potential and vitality. The electric vehicle industry has an urgent need for aluminum substrates with efficient heat dissipation to ensure the stable operation of the controller under complex working conditions; while in the field of LED lamps, high thermal conductivity aluminum substrates can significantly improve the luminous efficiency and extend the service life of lamps.

XDCPCBA PCB assembly factories and other companies, as key players in the PCB industry chain, play an irreplaceable role. They are professional PCBA processing plants and manufacturers that can undertake various electronic contract manufacturing projects. In terms of SMT PCB assembly, they rely on advanced equipment and exquisite craftsmanship to ensure assembly quality and efficiency. As a 2-30 layer PCB manufacturer, it can meet the needs of different customers for complex circuit boards; as a PCB supplier, it provides a rich and diverse product selection. At the same time, the free proofing service for 2-6 layer PCBs reduces the R&D costs and risks for customers.

PCB application industry fields are extremely wide. In the field of automotive electronics, not only electric vehicle controllers need PCBs, but also various electronic systems of traditional cars. In the communications industry, 5G base station construction, smart phones and other equipment have a strong demand for high-frequency and high-speed PCBs. In the field of consumer electronics, such as tablet computers and smart wearable devices, the performance and size requirements of PCBs are constantly increasing. In the field of industrial control, various automation equipment rely on PCBs to achieve precise control. In the field of medical electronics, the stable operation of medical equipment depends on high-quality PCBs. In the field of aerospace, the reliability and high temperature resistance of PCBs are extremely high.

In the face of ever-changing market demands and technical challenges, companies such as XDCPCBA PCB assembly factories need to continue to innovate, improve their technical level and production capacity, strengthen cooperation with various application industries, deeply understand customer needs, and provide customized solutions. Only in this way can we be invincible in the fierce market competition and contribute to the development of industries such as electric vehicles and LED lights and the electrification process of various industries.