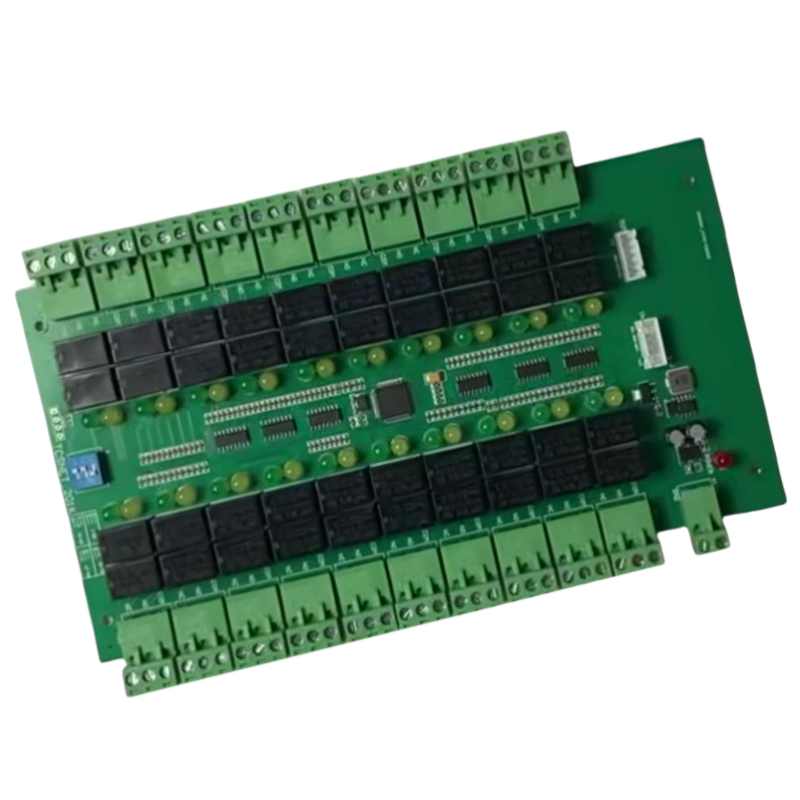

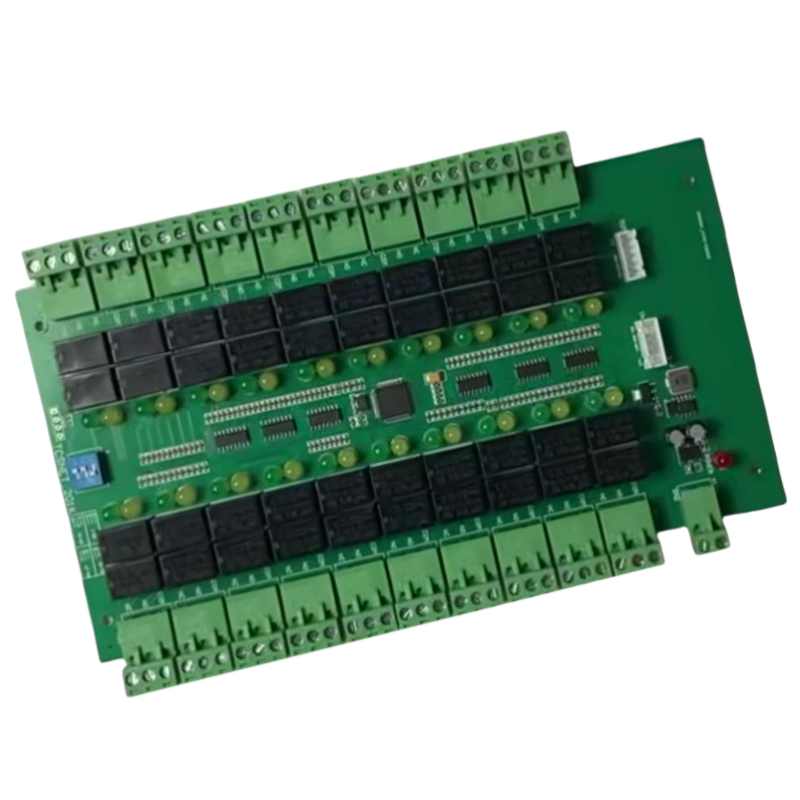

Technical Details

Material Selection:

We use high-quality FR-4 substrate materials with good insulation, heat resistance and mechanical strength to ensure the stability and reliability of PCB boards.

According to customer needs, we can provide PCB boards with different copper thicknesses to meet the requirements of different current loads.

Manufacturing process:

Adopt a hybrid assembly method combining advanced SMT (surface mount technology) and DIP (plug-in technology) to ensure the precise installation of components and the reliability of electrical connections.

During the welding process, we strictly control the welding temperature and welding time to avoid damage to the PCB board and components.

Quality control:

During the production process, we conduct multiple quality inspections, including AOI (automatic optical inspection), X-ray inspection, etc., to ensure the welding quality of the PCB board and the correct installation of components.

Strict functional and stability tests are carried out on the finished products to ensure that the products meet the customer's design requirements and performance standards.

Service process

Demand confirmation:

Communicate with customers to clarify the requirements of the elevator controller motherboard PCB assembly, including the number of layers, size, component list, etc.

Provide preliminary design solutions and quotations based on customer needs.

Design optimization:

Optimize the design solution based on customer feedback to ensure the feasibility and performance of the product.

Provide a DFM (design for manufacturability) report to point out problems that may affect PCB assembly and make suggestions for improvement.

Manufacturing:

Manufacture PCB boards and purchase components according to the optimized design solution.

Adopt advanced SMT and DIP technology for component assembly and welding.

Quality inspection:

Multiple quality inspections are carried out on the assembled PCB boards to ensure product quality.

Provide detailed quality inspection reports to let customers understand the performance and quality of the products.

Delivery and after-sales:

Deliver products to customers safely and on time according to customer requirements.

Provide comprehensive after-sales services, including technical support, product maintenance, etc., to ensure that customers receive timely and effective support during use.

Application analysis

The elevator controller motherboard PCB assembly plays an important role in the elevator control system. It ensures the stable operation of the elevator by precisely controlling the elevator's operating status, speed, safety protection, etc. At the same time, the elevator controller motherboard PCB assembly can also realize the functions of automatic operation, remote monitoring and management of the elevator, and improve the operating efficiency and safety of the elevator.

Competitive advantages

Professional team:

We have an experienced R&D team and production team, which can provide customers with professional technical support and customized solutions.

Advanced equipment:

We use advanced production equipment and testing equipment to ensure product quality and production efficiency.

Quality service:

We focus on customer service and provide one-stop solutions from design to production to ensure that customers receive timely and effective support during use.

Free sample service:

We especially provide 2-6 layer PCB free sample service, so that customers can fully verify the performance and quality of the product before formal production.

Electronic contract manufacturer and electronic manufacturing service

As an electronic contract manufacturer and electronic manufacturing service provider, XDCPCBA not only has strong production capabilities, but also focuses on close cooperation with customers. We develop products with customers, from design, manufacturing to testing, delivery, and participate in the whole process to ensure that the products meet customer expectations and requirements. At the same time, we also provide flexible production mode and fast response speed to meet the changing needs of customers.

In short, XDCPCBA PCBA manufacturer is an ideal choice for elevator controller motherboard PCB assembly. With a professional team, advanced equipment, high-quality services and strong competitive advantages, we are committed to providing customers with high-quality products and services.