In the UAVs where UAV technology is changing with each passing day, XDCPCBA has become a shining star in the chip industry with its strong PCBA manufacturing capabilities and rich experience in UAV PCB integration. As a leading UAV flight control and cross-country drone PCBA manufacturer, XDCPCBA focuses on providing customers with comprehensive UAV PCBA manufacturing services to promote the continuous development and progress of UAV technology.

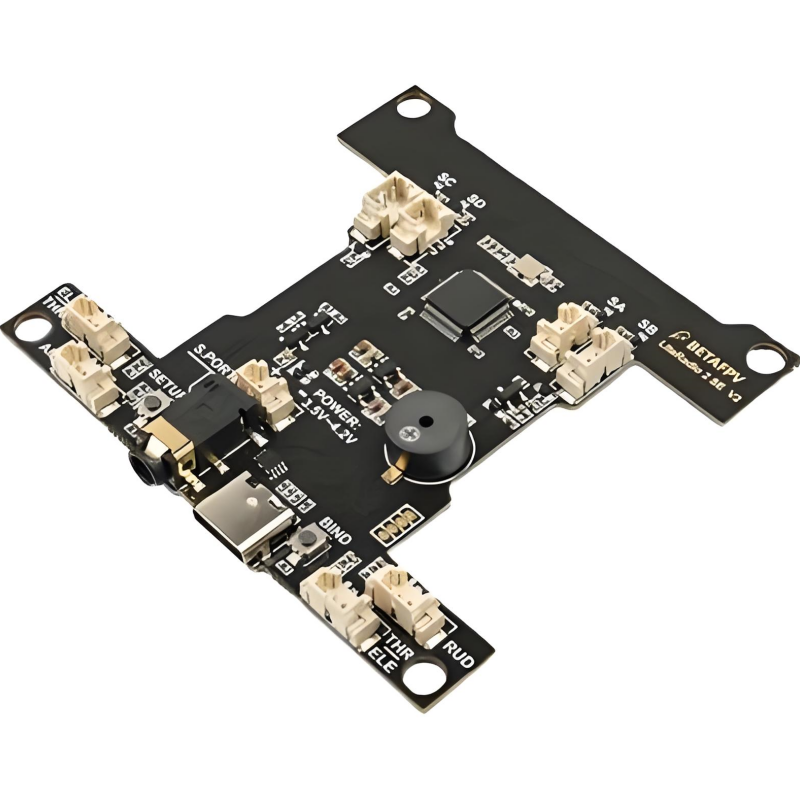

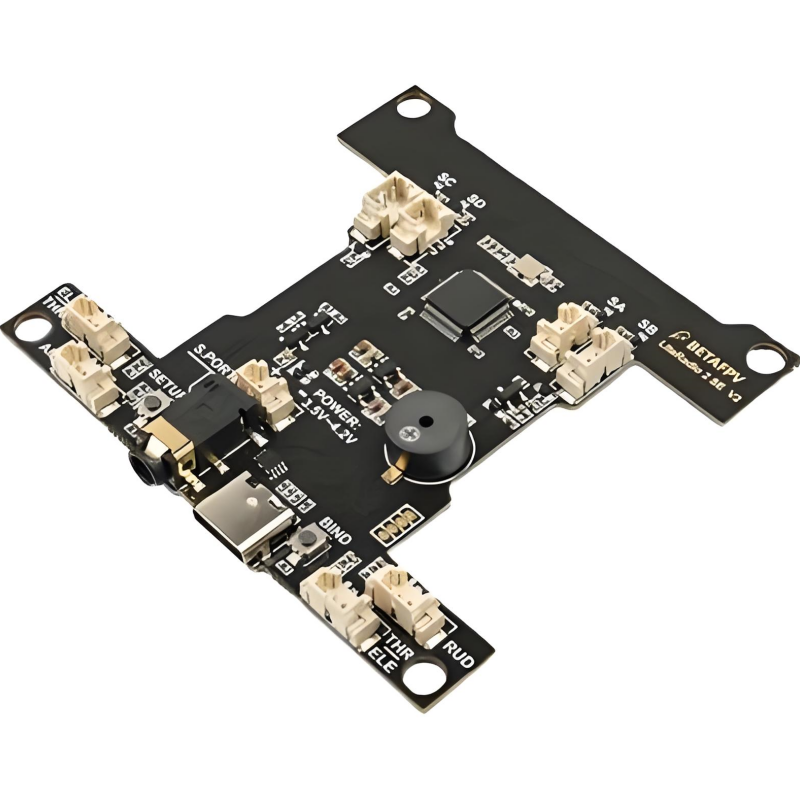

XDCPCBA is well aware of the high requirements of UAV flight control systems for circuit board performance. Therefore, in terms of PCB manufacturing, the company uses advanced production processes and materials to ensure that each PCB has excellent electrical performance and mechanical solution strength. Whether it is the complex design of multi-layer boards or the transmission of ultra-high-speed signals, XDCPCBA can provide high-quality solutions to meet the strict requirements of component stability and reliability.

In terms of PCBA manufacturing services, XDCPCBA has vigorously carried out its outstanding technical practice. The company has a group of professional PCBA processing, advanced automated production lines and sophisticated testing equipment. From component selection, team building to debugging, XDCPCBA can provide customers with a full range of customized services. Whether it is the flight control system, power system, or communication system of the drone, XDCPCBA can ensure stable signal transmission and low power consumption between components, thereby further improving the flight performance and stability of the drone.

In addition, XDCPCBA also specially provides 2-6 layer PCB free sample services to help customers better understand the quality and performance of the company's products. The launch of this initiative not only demonstrates XDCPCBA's commitment to customer satisfaction, but also further enhances the company's competitiveness and influence in the industry.

As an electronic contract manufacturer and electronic manufacturing service giant, XDCPCBA always adheres to customer-centricity and continuously improves its own technology and service strength. Whether it is product design, production progress, or quality control, XDCPCBA can maintain close contact with customers to ensure that customer needs are met. At the same time, XDCPCBA also pays attention to the level of technological innovation and R&D investment, and continuously launches more advanced and advanced UAV PCBA solutions to meet customers' needs for high-performance and high-reliability solution products.

In the future, XDCPCBA will continue to uphold the principle of "quality first, customer first" to provide global customers with better quality UAV PCBA manufacturing services and help customers achieve greater success in the field of UAVs. At the same time, XDCPCBA will continue to explore and innovate, provide customers with more honest and higher-quality electronic manufacturing services, and jointly promote the continuous development and progress of UAV technology.