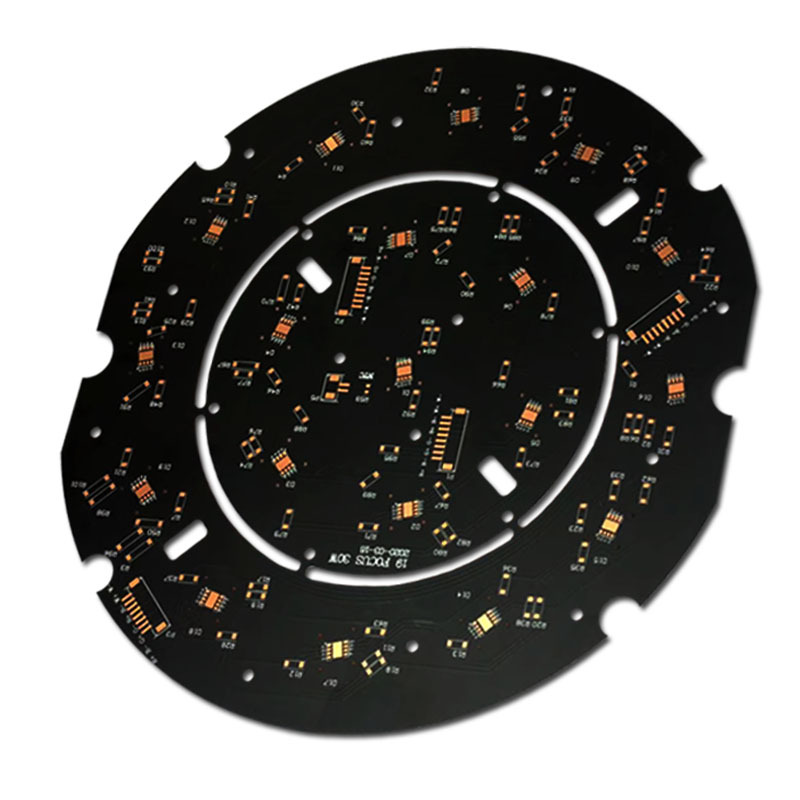

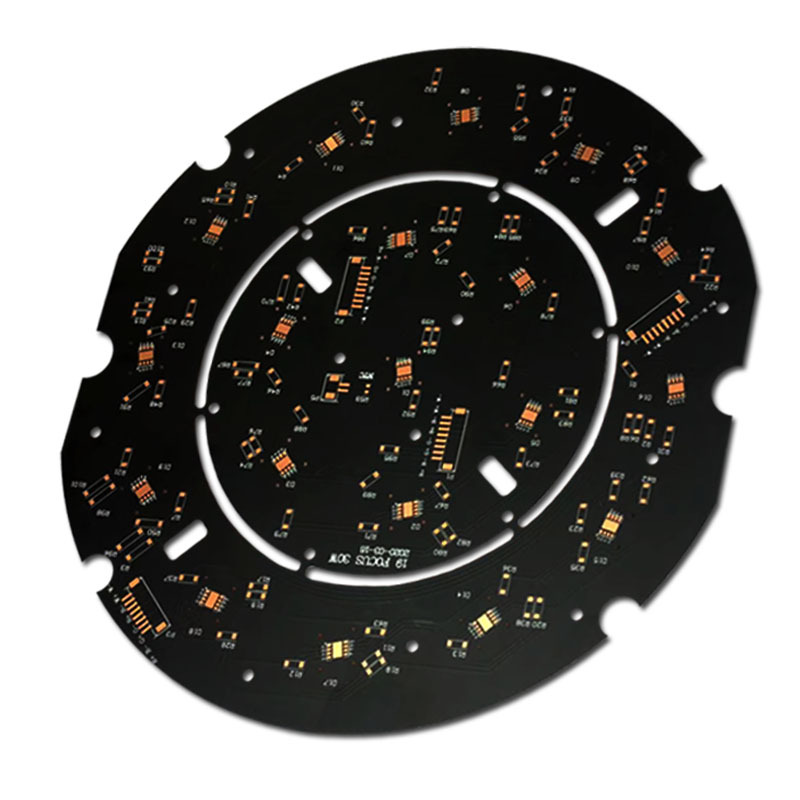

The manufacturing of 3MM single-sided copper substrate PCB and new energy electric control LED copper substrate PCB has become the focus of the industry. This type of PCB plays a key role in many fields with its excellent performance. XDCPCBA PCB assembly factory and other companies, as an important force in the PCB industry chain, integrate multiple identities such as PCBA processing plant, PCBA manufacturer, and electronic contract manufacturer.

They have advanced production equipment and professional technical teams, and are experienced in SMT PCB assembly, which can ensure high precision and high quality of assembly. As a 2-30 layer PCB manufacturer, it can meet the diverse needs of different customers for the number of layers and complexity of circuit boards; as a PCB supplier, it provides a rich variety of product options to meet the diversified needs of the market. The free proofing service of 2-6 layers PCB reduces the R&D cost and risk for customers and accelerates the product's listing process.

The application industry of PCB is extremely wide. In the field of automotive electronics, the electronic control systems of electric vehicles and various sensors of traditional vehicles require high-performance PCBs to ensure stable operation; in the field of consumer electronics, smart phones, tablet computers, smart wearable devices, etc. have put forward higher requirements for the miniaturization and high integration of PCBs; in the communications industry, 5G base station construction, optical fiber communication equipment, etc. are inseparable from high-speed and high-frequency PCBs; in the field of industrial control, automated production lines, industrial robots, etc. rely on PCBs for precise control; in the field of medical electronics, medical imaging equipment, monitors, etc. have extremely high requirements for the reliability and stability of PCBs; in the field of aerospace, there are special requirements for the high temperature resistance and radiation resistance of PCBs.

Faced with ever-changing market demands and technical challenges, companies such as XDCPCBA PCB assembly factories need to continue to innovate, improve their technical level and production capacity, strengthen cooperation with various application industries, deeply understand customer needs, and provide customized solutions to maintain their leading position in the fierce market competition.