Introduction

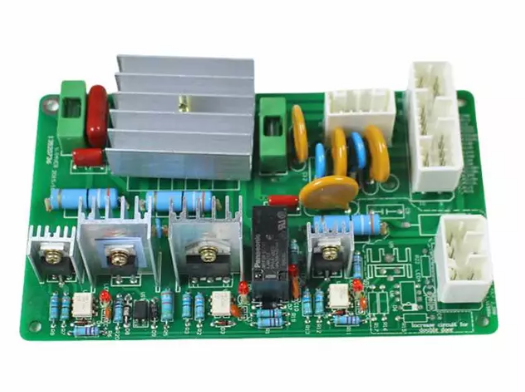

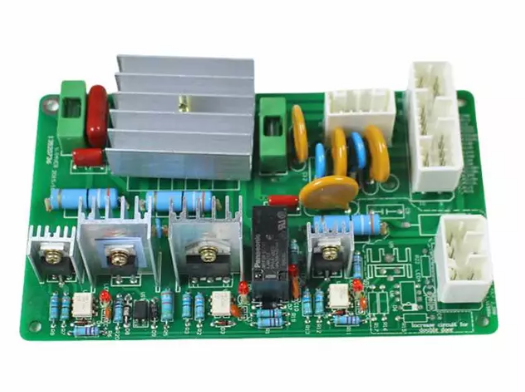

Choosing the right PCB manufacturer is crucial for any electronic project. The quality of the PCB directly impacts the performance, reliability, and cost-effectiveness of your device. Whether you're working on a simple gadget or a complex industrial system, the right manufacturer makes all the difference.

In this article, we will explore the key factors to consider when selecting a PCB manufacturer. You'll learn how to evaluate their capabilities and make an informed decision that meets your specific needs.

Factors to Consider When Choosing a PCB Manufacturer

Quality Standards and Certifications

Quality is paramount when it comes to PCB manufacturing. The reliability of your final product directly correlates with the manufacturer's ability to maintain consistent quality. Look for manufacturers who hold ISO 9001 certification, as it demonstrates adherence to quality management standards that ensure the PCB is produced with high precision. UL certification is also crucial, particularly for industries where safety is a concern, such as consumer electronics and automotive sectors.

Additionally, some industries require more specific certifications. For example, IPC-A-600 ensures that the PCB meets the standards for acceptable quality levels in manufacturing. AS9100 (for aerospace) and ISO 13485 (for medical devices) are other important certifications depending on the application of your PCB. The presence of these certifications guarantees that the manufacturer follows stringent processes that result in high-quality outputs and adherence to industry-specific requirements.

Factor |

Description |

Quality Standards |

Look for certifications such as ISO 9001, UL, and IPC-A-600 to ensure high quality. |

Manufacturing Capabilities |

Ensure the manufacturer can handle your specific PCB type and materials. |

Experience |

Choose a manufacturer with experience in your industry for reliable results. |

Customer Service |

Evaluate communication and post-production support for smooth collaboration. |

Manufacturing Capabilities and Technology

Each PCB manufacturer has its own capabilities, and it’s crucial to choose one whose technologies align with your specific needs. Some manufacturers specialize in high-density interconnects (HDI), which is critical for mobile devices and advanced electronic systems. Others may focus on flexible PCBs or rigid-flex designs, both of which are used in industries like aerospace and automotive where space-saving designs are important.

Moreover, it’s essential to understand what types of PCBs the manufacturer can produce. Can they handle single-sided, double-sided, or more advanced multilayer PCBs? The choice of materials is another consideration. Manufacturers who provide a variety of substrates (e.g., FR4, polyimide, aluminum-based PCBs) offer more flexibility in design, which can be essential for certain applications.

Another critical factor is the production equipment. Modern manufacturers should use state-of-the-art machinery such as automated optical inspection (AOI) systems and laser drills for microvias, which ensures that the PCBs are produced with high precision and efficiency. The level of automation and technology used can also influence the turnaround time and cost-effectiveness of the production process.

Experience and Industry Expertise

Experience plays a crucial role in ensuring that a manufacturer can meet your requirements. Manufacturers who have been in the PCB industry for years have refined their processes and learned how to troubleshoot common design and production challenges. This experience is invaluable, especially if you are working on a complex design or a product with unique requirements.

Look for manufacturers who have specific experience in your industry. Whether you’re in medical, automotive, or telecommunications, a manufacturer who understands the challenges and standards of your field can provide valuable insights. They can help you avoid common pitfalls and offer advice on design optimization, material selection, and manufacturing techniques to improve the final product.

Evaluating the PCB Manufacturer’s Performance

Pricing and Lead Times

Pricing is, of course, an important factor, but it should not be the only consideration. The cost of a PCB depends on many factors such as complexity, materials used, and the quantity ordered. It's important to have transparent pricing from the manufacturer, so you understand what you’re paying for—whether it’s for the PCB itself, additional testing, tooling, or assembly.

Lead times are equally important. A manufacturer with long lead times can delay your product launch, so it’s essential to choose one that can meet your project deadlines. Some manufacturers offer rush services, but this may come with an extra charge. It’s crucial to balance cost, speed, and quality to ensure that you are getting the best value for your project.

Customer Service and Communication

Customer service is another vital aspect to consider. Effective communication with your PCB manufacturer ensures that your design intentions are understood, and that any potential issues are addressed promptly. Whether it’s clarifying technical requirements or discussing design changes, the ability to communicate clearly and efficiently with the manufacturer can prevent costly mistakes during production.

Furthermore, assess the level of support the manufacturer provides during the design process. Do they offer assistance with design for manufacturability (DFM)? A manufacturer who collaborates with you early in the design phase can help optimize the PCB design, reducing the likelihood of issues during production. Post-production support is also crucial—ensure the manufacturer offers assistance with reorders, troubleshooting, or any issues that arise once the PCBs are in use.

Location and Shipping Considerations

When choosing a PCB manufacturer, you need to consider the location of the manufacturer. Domestic manufacturers offer the advantage of faster shipping times and easier communication due to time zone alignment and language familiarity. On the other hand, offshore manufacturers, particularly those based in countries like China, India, and Taiwan, often offer more competitive pricing, though the trade-off can be longer lead times and potential communication barriers.

The shipping logistics are also critical. A local manufacturer might save you on shipping costs, but an offshore manufacturer with optimized logistics can still be cost-effective in the long run, especially if they have strong international shipping channels. Make sure the manufacturer can meet your shipping requirements and that their location fits with your timeline and budget.

Types of PCB Manufacturers

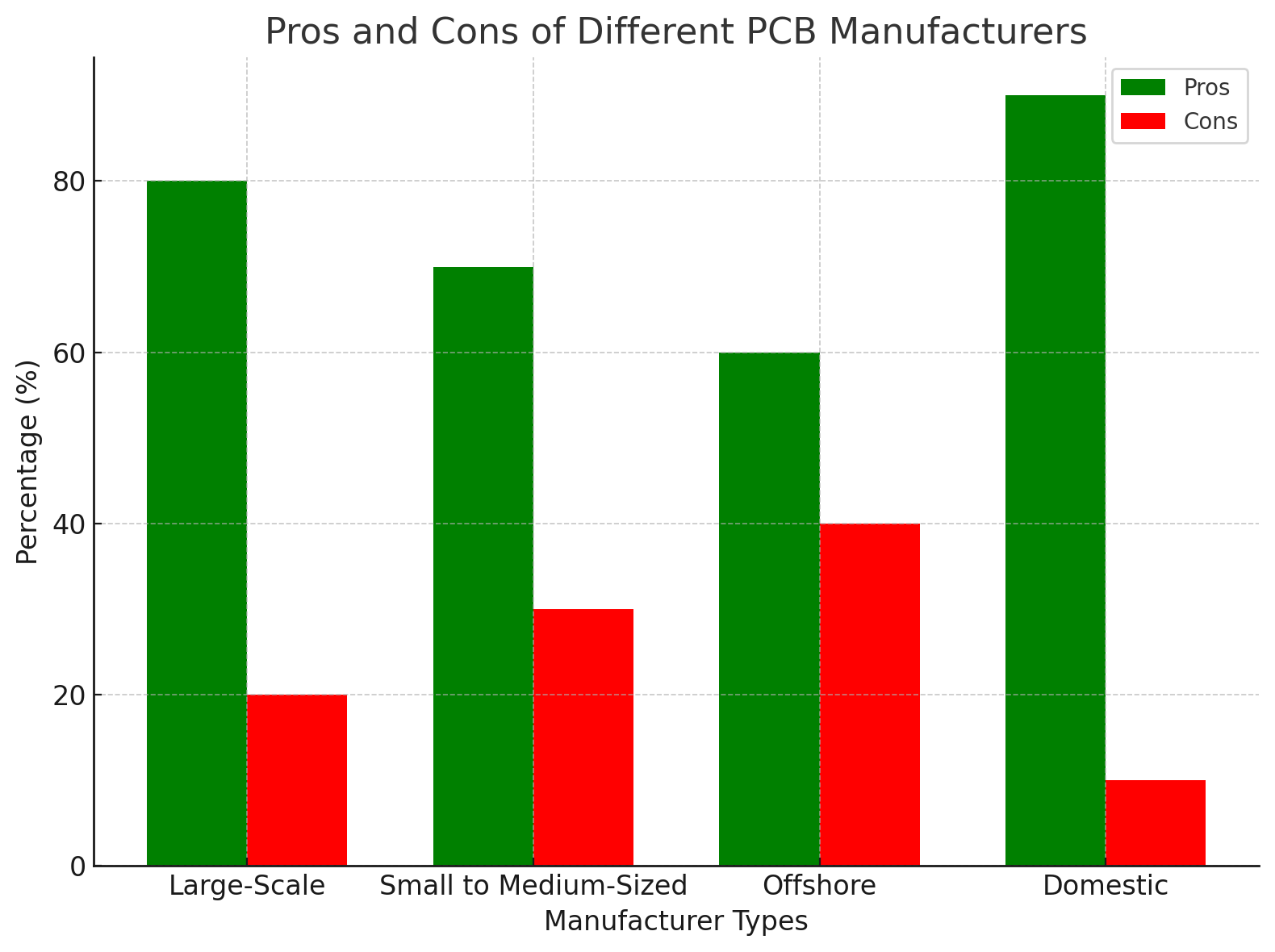

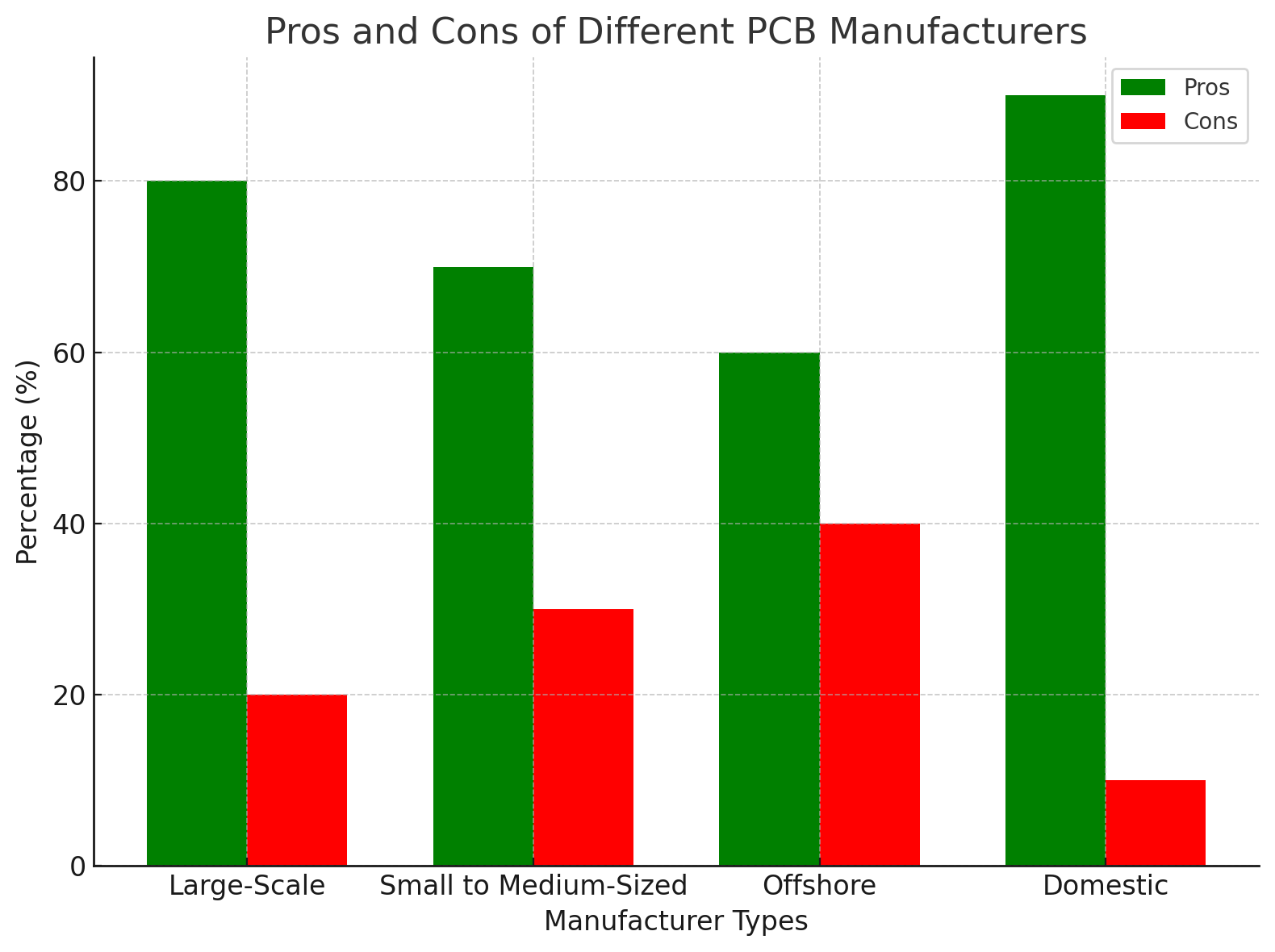

Large-Scale Manufacturers

Large-scale manufacturers are capable of handling high-volume orders and often have the resources to provide lower unit costs. They typically operate with automated systems that streamline production, which can significantly reduce labor costs. However, the downside is that they may not be as flexible or responsive to specific needs and may not offer the personalized service smaller manufacturers can provide.

Large manufacturers are ideal for mass-market products where cost reduction and volume are the priorities, but they might not be the best option for niche projects requiring specialized PCB designs.

Small to Medium-Sized Manufacturers

Small to medium-sized PCB manufacturers are typically more agile and can provide more tailored services. These manufacturers are better equipped to handle low-volume, specialized orders. They often have more personalized customer service, which allows for more communication and adjustments throughout the manufacturing process.

Although their per-unit costs may be higher compared to large-scale manufacturers, they are often more capable of meeting tight specifications and providing customized solutions. These manufacturers are ideal for specialized industries or products with unique requirements.

Offshore Manufacturers

Offshore manufacturers, particularly those located in countries with lower labor costs, can offer significant savings. However, they typically come with longer lead times and may pose challenges in communication, particularly if there are language barriers. Despite these issues, offshore manufacturers can be a good choice for projects where cost savings are essential, and the timeline is flexible.

Domestic Manufacturers

Domestic PCB manufacturers offer the benefit of faster lead times and easier communication. They are generally more familiar with local regulatory standards, which can be important for products with specific compliance requirements.

Manufacturer Type |

Pros |

Cons |

Large-Scale Manufacturers |

High-volume production, lower cost per unit |

Less flexibility, generic solutions |

Small to Medium-Sized Manufacturers |

Personalized service, flexible for specialized orders |

Higher per-unit cost, limited production capacity |

Offshore Manufacturers |

Lower labor costs, cost savings on materials |

Longer lead times, potential language barriers |

Domestic Manufacturers |

Faster lead times, better quality control |

Higher costs compared to offshore options |

Questions to Ask When Choosing a PCB Manufacturer

When evaluating a PCB manufacturer, ask questions that focus on their capabilities, quality, and customer service:

● Quality Standards and Certifications: What certifications do you hold? How do you ensure quality throughout the production process?

● Manufacturing Capabilities: What types of PCBs can you produce? What is the maximum layer count you can handle?

● Lead Times and Pricing: What are your typical lead times for different PCB sizes? Do you offer rush services, and what are the costs?

Tips for a Successful Partnership with a PCB Manufacturer

Provide Clear Documentation and Specifications

Providing clear and accurate design files is essential to prevent errors and delays. Ensure that your Gerber files, BOM (Bill of Materials), and assembly files are accurate and complete to avoid unnecessary revisions during the production process.

Build a Long-Term Relationship

Establishing a long-term partnership with your PCB manufacturer can lead to better pricing, faster turnaround times, and consistent quality over time. A manufacturer that understands your needs and workflow will be more efficient in future projects.

Communication is Key

Maintaining clear and consistent communication throughout the production process ensures that any issues or changes are addressed quickly. Regular updates and feedback can help streamline the production process and reduce the likelihood of errors.

Conclusion

Choosing the right PCB manufacturer is key to the success of your electronic projects. The right manufacturer ensures high-quality production, timely delivery, and cost-effectiveness. Factors like quality standards, experience, and customer service play crucial roles. By carefully evaluating these aspects, you can find a reliable partner. Companies like XDCPCBA offer high-quality, reliable products designed to meet the specific needs of your project, ensuring your success in the competitive market.

FAQ

Q: What factors should I consider when choosing a PCB manufacturer?

A: When choosing a PCB manufacturer, consider quality standards, manufacturing capabilities, experience, and customer service to ensure your project meets the highest standards.

Q: Why is experience important when selecting a PCB manufacturer?

A: An experienced PCB manufacturer understands industry-specific requirements and can provide valuable insights to optimize your design and production.

Q: How does the location of a PCB manufacturer affect my project?

A: The location of a PCB manufacturer impacts shipping costs, delivery times, and communication ease. Domestic manufacturers offer faster lead times, while offshore options may provide cost savings.

Q: How can I ensure my PCB manufacturer meets my quality expectations?

A: Ask for certifications like ISO 9001 and UL, and inquire about their quality control processes to ensure the PCB manufacturer maintains high production standards.