Printed Circuit Board Assembly Manufacturer: Precision Manufacturing, Adapting to Multiple Application Scenarios

In today's era of rapid technological development, electronic devices have penetrated into all aspects of people's lives and work, from daily smartphones and tablets to automation equipment in industrial production, precision instruments in the medical field, and the intelligent upgrade of automotive electronic systems. All of them are inseparable from the key link of Printed Circuit Board Assembly (PCB assembly). As the "nervous system" of electronic equipment, PCB carries the electrical connections between electronic components. Its quality and performance directly determine the stability and reliability of the entire electronic equipment. Therefore, it is very important to choose a PCB assembly manufacturer that can accurately manufacture and adapt to various application scenarios. XDCPCBA, as a leading company in the industry, has become the preferred partner of many customers with its outstanding technical strength and strict quality control.

Precision manufacturing, casting high-quality PCB assembly

XDCPCBA is well aware that precision manufacturing is the core of PCB assembly. In order to achieve this goal, the company started from multiple aspects and continuously improved its manufacturing capabilities.

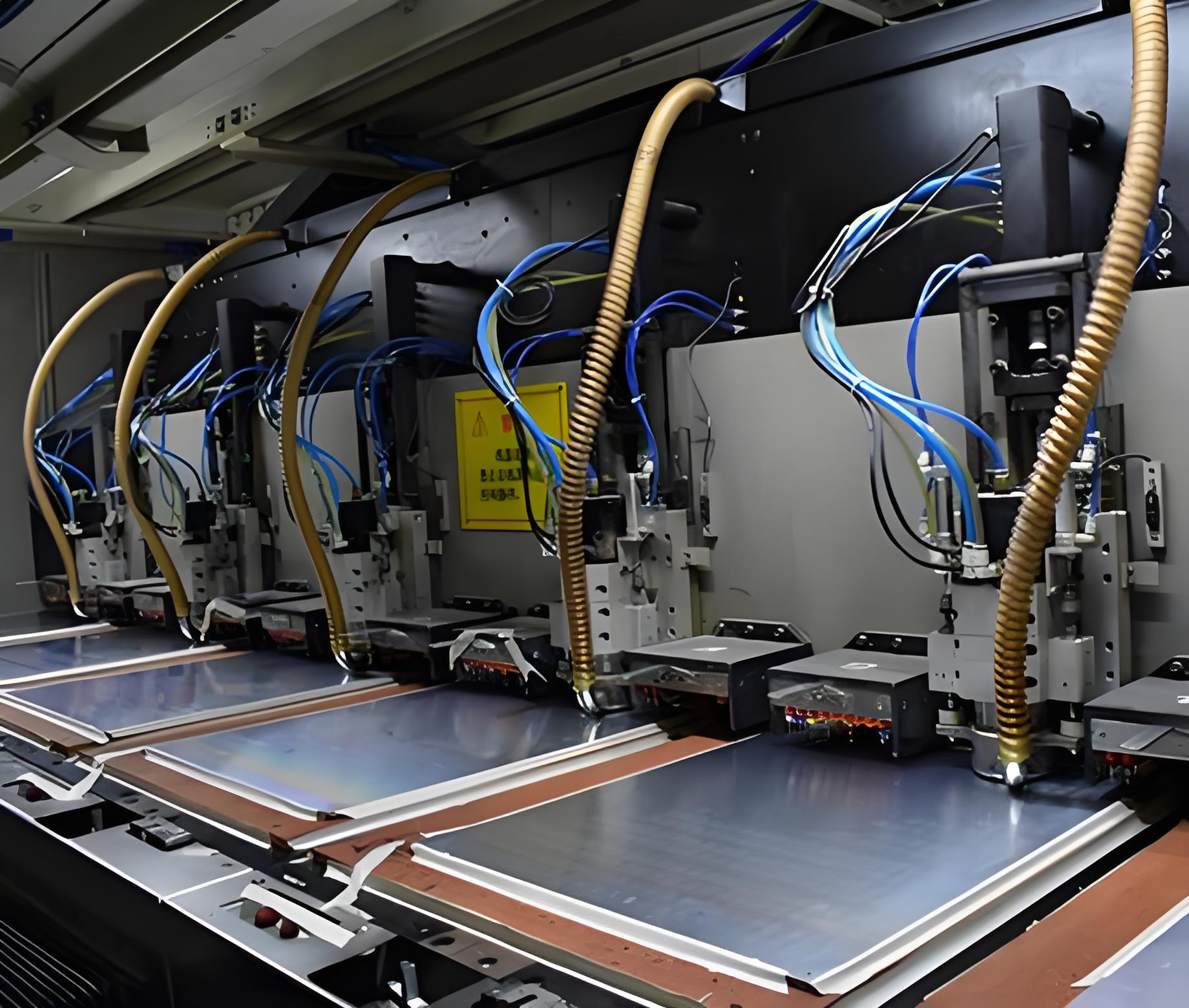

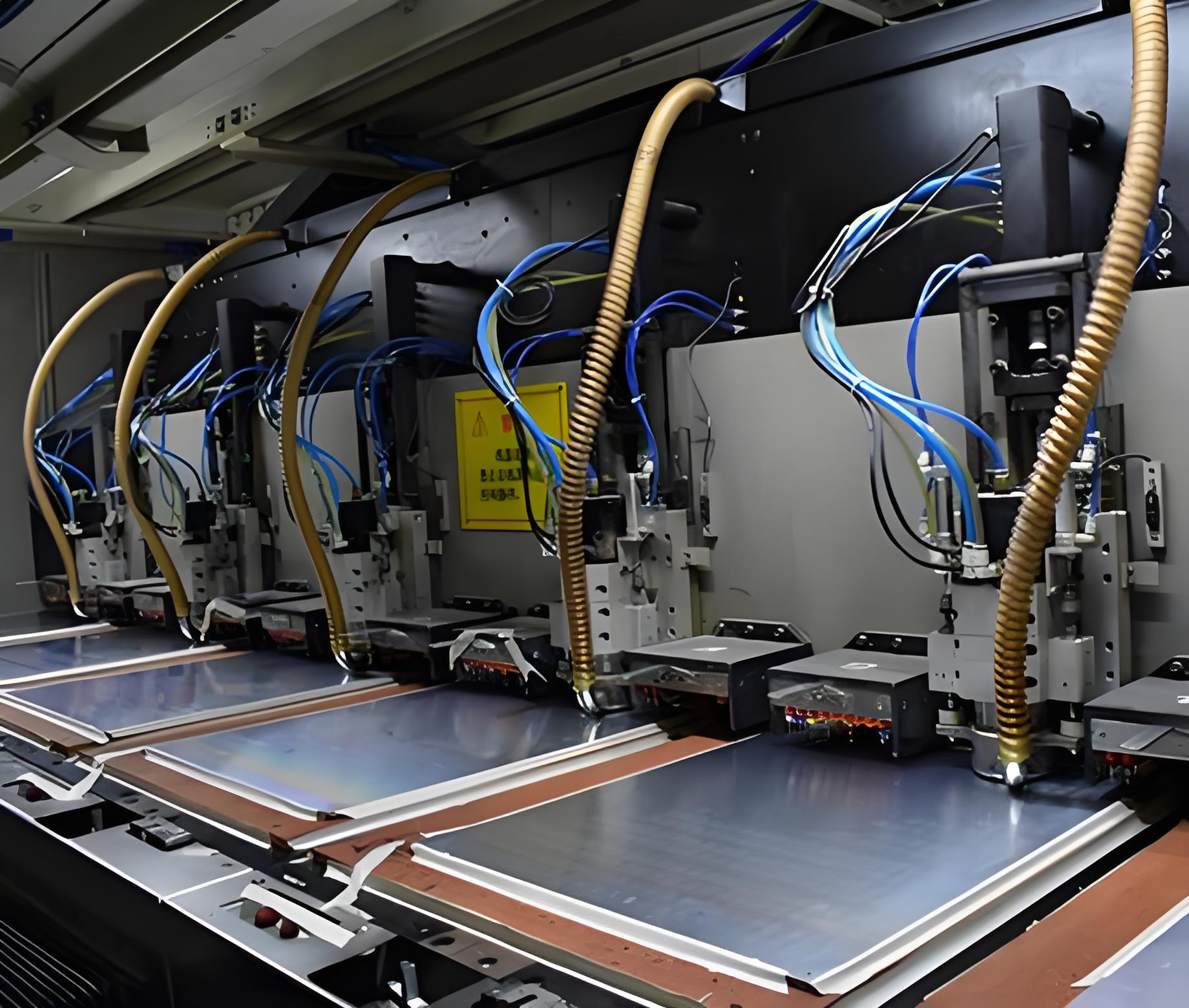

In terms of production equipment, XDCPCBA has introduced internationally advanced SMT patch equipment, AOI optical inspection equipment, X-Ray inspection equipment, etc. These equipment have the characteristics of high precision, high speed and high stability, which can ensure the precise placement and welding quality of electronic components. For example, SMT patch equipment can achieve micron-level placement accuracy, greatly improving the assembly density and reliability of PCBs; AOI optical inspection equipment can conduct a full range of inspections on the mounted PCBs, timely detect and remove defective products, and effectively reduce the defective rate of products.

In terms of process technology, XDCPCBA has a professional technical team who constantly explores and innovates, and has developed a set of PCB assembly processes suitable for different application scenarios. Whether it is for high-density, small-pitch electronic components, or for PCBs with special materials and special process requirements, XDCPCBA can provide professional solutions. At the same time, the company has also established a strict quality control system, from raw material procurement, production process monitoring to finished product inspection, every link is strictly controlled to ensure that each PCB meets high quality standards.

Diverse application fields to meet the needs of different industries

PCB has a wide range of applications, and different industries have different performance and requirements for PCB. With its precision manufacturing capabilities, XDCPCBA can provide customized PCB assembly solutions for various industries.

Consumer electronics: As consumers have higher and higher requirements for the appearance, performance and functions of electronic products, the replacement speed of consumer electronic products is also getting faster and faster. XDCPCBA keeps up with market trends and provides thin and high-performance PCB assembly services for consumer electronic products such as smartphones, tablets, and smart wearable devices. The company uses advanced materials and processes to ensure that PCBs have high density, high reliability, low power consumption and other characteristics to meet the needs of consumer electronic products for high performance and miniaturization.

Industrial control field: Industrial control equipment usually needs to operate stably for a long time in harsh environments, and has extremely high requirements for the stability and reliability of PCBs. XDCPCBA selects high-quality materials and uses special process treatment to ensure that PCBs have excellent high temperature resistance, corrosion resistance, vibration resistance and other properties. For example, in industrial automation production lines, the PCBs provided by XDCPCBA can withstand harsh environments such as high temperature, high humidity, and dust, ensuring the normal operation of equipment and improving production efficiency and product quality.

Medical equipment field: Medical equipment is directly related to people's life and health, and has extremely high requirements for the accuracy, stability and safety of PCB. XDCPCBA uses special materials and processes to ensure that PCB can operate accurately and stably in medical equipment. For example, in medical imaging equipment, the PCB provided by XDCPCBA can achieve high-precision signal transmission and processing, provide doctors with clear and accurate diagnostic images, and improve the accuracy of medical diagnosis.

Automotive electronics field: Automotive electronics is the trend of future automotive development, and automotive electronic systems have extremely high requirements for the safety and reliability of PCB. XDCPCBA cooperates with many well-known automobile manufacturers to jointly develop PCB products that meet automotive industry standards. The company uses special materials and processes to ensure that PCB can operate stably in the complex electromagnetic environment of the car, and at the same time has good shock resistance, high temperature resistance and other properties, providing protection for the safe driving of the car.

Free proofing service to reduce customer risks

In order to help customers reduce R&D costs and risks, XDCPCBA has specially launched a 2-6 layer PCB free proofing service. Customers only need to provide design files, and XDCPCBA can provide customers with high-quality PCB samples in a short time. This service not only allows customers to verify the performance and quality of PCBs in the early stages of product development, but also promptly discovers and optimizes problems in the design, avoiding losses caused by discovering problems after mass production. Through free proofing services, customers can work with XDCPCBA with greater confidence to jointly promote the smooth progress of the project.

Multiple identities, providing one-stop services

XDCPCBA is not only a PCB assembly factory, but also a comprehensive electronic manufacturing service provider that integrates multiple identities such as PCBA processing factory, PCBA manufacturer, and electronic contract manufacturer. The company can provide customers with one-stop services from PCB design, procurement, production to testing, so that customers no longer have to worry about cumbersome supply chain management.

XDCPCBA also performs well in the selection of PCB suppliers. With its strong supply chain integration capabilities, the company has established long-term and stable cooperative relationships with many well-known electronic component suppliers around the world to ensure that customers can obtain high-quality and low-cost electronic components. Whether it is the high-end needs of 2-30 layer PCB manufacturers or the complex projects of electronic contract manufacturers, XDCPCBA can meet customer needs with precise manufacturing capabilities and high-quality services.

Conclusion

In the electronics manufacturing industry, precision manufacturing is the core competitiveness of PCB assembly manufacturers. As a professional Printed Circuit Board Assembly manufacturer, XDCPCBA always adheres to customer-centricity and precision manufacturing as the cornerstone to provide high-quality PCB assembly solutions for customers in different application fields. Whether it is consumer electronics, industrial control, medical equipment or automotive electronics, XDCPCBA can meet the diverse needs of customers with its excellent technical strength and strict quality control.

Choosing XDCPCBA means choosing professionalism and reliability. XDCPCBA PCB assembly factory, PCBA processing factory, PCBA manufacturer, electronic contract manufacturer, SMT PCB assembly, 2-30 layer PCB manufacturer, PCB supplier, 2-6 layer PCB free proofing service - these are not only XDCPCBA's identity labels, but also its commitment to create value for customers. Let us join hands with XDCPCBA to open a new chapter in electronic manufacturing!