Functional Implementation and Testing in Smart Home PCB Assembly

Smart home devices integrate multiple technologies—wireless communication, sensor interfacing, and power management—into compact PCB assemblies. Achieving seamless functionality requires careful design of hardware circuits, firmware logic, and rigorous testing protocols to ensure reliability across diverse operating conditions.

Wireless Connectivity Integration and Validation

Smart home PCBs rely on wireless protocols like Wi-Fi, Bluetooth Low Energy (BLE), or Zigbee to enable remote control and data exchange. Implementing these protocols involves selecting compatible RF modules or integrating transceiver chips with antenna designs optimized for small form factors. For example, printed antennas etched onto the PCB reduce space requirements but demand precise tuning to match target frequency bands (e.g., 2.4 GHz for Wi-Fi/BLE).

Testing wireless connectivity begins with RF parameter verification, including output power, sensitivity, and frequency accuracy. Spectrum analyzers and vector network analyzers (VNAs) measure these metrics to confirm compliance with regulatory standards like FCC Part 15 or ETSI EN 300 328. During assembly, shielding techniques—such as metal cans or embedded ground planes—are evaluated to minimize electromagnetic interference (EMI) between RF circuits and digital components, which could degrade signal quality or cause unintended disconnections.

Interoperability testing ensures the device communicates reliably with smartphones, gateways, or cloud platforms. Automated test scripts simulate user interactions, such as sending control commands via a mobile app or receiving firmware updates over-the-air (OTA). Stress tests assess performance under weak signal conditions, packet loss, or concurrent connections to multiple devices, which are common in multi-user smart home environments.

Sensor Fusion and Data Processing Accuracy

Smart home PCBs incorporate sensors for motion detection, temperature monitoring, ambient light measurement, or air quality analysis. Each sensor requires dedicated signal conditioning circuits, including amplifiers, filters, and analog-to-digital converters (ADCs), to convert raw data into digital formats usable by microcontrollers. For instance, a thermistor-based temperature sensor may need a voltage divider and low-pass filter to eliminate noise from power supply fluctuations.

Calibration is critical for sensor accuracy. Manufacturing processes introduce variations in component values, so PCBs undergo individual calibration to adjust offset and gain parameters. For example, a humidity sensor might be exposed to controlled environments (e.g., 25°C at 50% RH) during testing, with firmware updated to correct measurement errors. Cross-validation against reference instruments ensures sensors meet specified tolerances before deployment.

Data fusion algorithms combine inputs from multiple sensors to enhance system intelligence. A smart thermostat, for example, might use occupancy data from a motion sensor to adjust heating schedules, requiring real-time processing and low-latency communication between components. Testing verifies that sensor data is processed correctly under varying conditions, such as sudden temperature changes or rapid motion detection, to prevent false triggers or delayed responses.

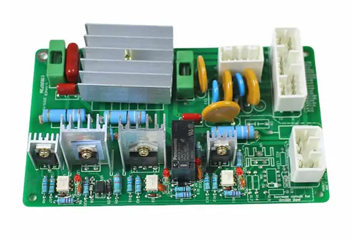

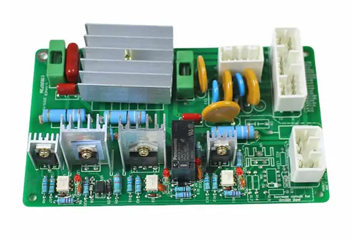

Power Management and Energy Efficiency Optimization

Smart home devices often operate on batteries or low-voltage DC sources, necessitating efficient power management. PCB designs include voltage regulators, DC-DC converters, and power gating circuits to distribute power appropriately to different subsystems. For example, a wireless module might enter sleep mode during inactivity, drawing microamperes of current, while a microcontroller remains active to process sensor data.

Dynamic power scaling is tested to confirm that components transition smoothly between low-power and active states. Oscilloscopes and current probes measure power consumption during different operational modes, identifying anomalies like excessive leakage currents or inefficient voltage regulation. Firmware optimizations, such as reducing clock frequencies or disabling unused peripherals, are validated to extend battery life without compromising functionality.

Thermal management also plays a role in power efficiency. High-current components, such as motor drivers for smart locks, generate heat that could affect nearby sensors or wireless modules. Infrared thermometers and thermal cameras inspect PCB hotspots during continuous operation, ensuring temperatures stay within safe limits. Heat sinks or thermal vias may be added to improve heat dissipation, with retesting confirming their effectiveness.

End-to-End System Testing Under Real-World Conditions

Functional testing extends beyond individual components to validate the entire smart home ecosystem. Integration tests verify that the PCB interacts correctly with external devices, such as cloud servers or voice assistants. For example, a smart speaker PCB must process voice commands, transmit audio data to the cloud, and receive responses within acceptable latency thresholds.

User experience testing evaluates intuitive operation and error handling. Testers simulate common scenarios, like pairing devices with a smartphone app, setting up automation rules, or recovering from network outages. Edge cases, such as invalid sensor readings or corrupted firmware downloads, are introduced to ensure the system responds gracefully without crashing or exposing security vulnerabilities.

Long-term reliability testing subjects PCBs to accelerated life cycles, including repeated power cycling, temperature extremes, and mechanical stress (e.g., vibration for wall-mounted devices). These tests uncover latent defects in solder joints, component attachments, or material degradation that might not appear during short-term functional checks.

By addressing wireless connectivity, sensor accuracy, power efficiency, and system-level reliability, manufacturers can deliver smart home PCB assemblies that meet consumer expectations for seamless, intuitive, and long-lasting performance.