Functional Requirements for PCB Manufacturing in Educational Equipment

Educational equipment, ranging from interactive whiteboards and language labs to science experiment kits and coding robots, relies on PCBs to deliver reliable, user-friendly functionality. These devices must balance performance, safety, and cost-effectiveness while supporting diverse learning activities. This article explores key functional requirements for PCBs in educational applications, focusing on connectivity, durability, and power efficiency to meet the demands of modern classrooms and labs.

Multi-Modal Connectivity for Interactive Learning Environments

Educational devices often require seamless integration with other hardware, software, and cloud-based platforms to enable collaborative or remote learning. PCBs must support a variety of connectivity options, including wired interfaces like USB, HDMI, and Ethernet, as well as wireless protocols such as Wi-Fi, Bluetooth, and NFC. For example, interactive whiteboards use HDMI for high-definition video output and USB for touchscreen or stylus input, while coding robots rely on Bluetooth for smartphone or tablet control. Manufacturers design PCBs with modular connector layouts to accommodate different interfaces without increasing board complexity, ensuring compatibility with existing educational infrastructure.

Low-latency communication is critical for real-time interactions, such as live video streaming in virtual classrooms or instant feedback in gamified learning apps. PCBs optimize signal routing for high-speed data lines, using differential pairs and controlled impedance traces to minimize transmission delays. For wireless devices, PCBs incorporate antennas with directional patterns tailored to classroom layouts, improving signal strength and reducing interference from neighboring networks. Some designs also include dual-band Wi-Fi modules to support both 2.4GHz and 5GHz frequencies, ensuring stable connections in crowded educational environments.

Interoperability with third-party devices and software is another priority. PCBs may integrate standard communication protocols like MQTT or REST APIs to enable data exchange with learning management systems (LMS) or educational apps. For example, science sensors connected to a PCB could transmit experimental data to an LMS for analysis, while coding robots might use serial communication to receive instructions from a development environment. Manufacturers perform compatibility testing during production to verify that PCBs work with popular educational tools and platforms, reducing setup time for educators.

Durability and Safety for High-Usage Classroom Settings

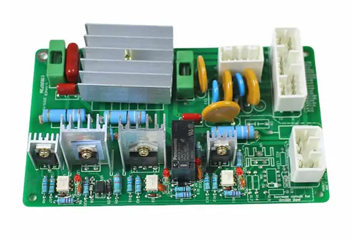

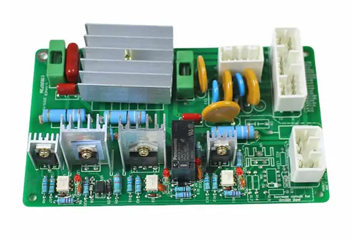

Educational equipment is subjected to frequent handling, accidental drops, and exposure to dust or spills, requiring PCBs that withstand physical stress without compromising functionality. Robust PCB designs use high-quality materials, such as FR-4 laminates with enhanced glass transition temperatures (Tg) to resist warping under heat generated by components like processors or LED displays. For portable devices like tablets or handheld microscopes, PCBs may incorporate flexible sections or rigid-flex architectures to absorb shocks and prevent solder joint fractures during drops.

Safety certifications are mandatory to protect students and educators from electrical hazards. PCBs comply with standards like IEC 62368-1 for audio/video and IT equipment, which specifies requirements for insulation, creepage distances, and flame resistance. Components are selected based on their safety ratings, such as X2 capacitors for power supply filtering or fuses with precise trip currents to prevent overcurrent conditions. Manufacturers also implement protective circuits, such as overvoltage clamps or reverse-polarity diodes, to shield PCBs from power surges or incorrect battery installation.

Environmental resilience is addressed through conformal coatings or potting compounds that shield PCBs from moisture, chemicals, and dust. For example, science experiment kits used in chemistry labs may require PCBs with hydrophobic coatings to resist corrosion from acidic or alkaline solutions. Some designs use hermetic sealing for critical components like sensors or wireless modules to ensure long-term reliability in harsh conditions. Manufacturers perform accelerated life testing, including humidity exposure and thermal cycling, to validate that PCBs maintain performance over years of classroom use.

Power Efficiency for Cost-Effective and Sustainable Operation

Educational institutions often operate on tight budgets, making power efficiency a key consideration for PCB designs. Low-power components, such as microcontrollers with sleep modes or LED drivers with adjustable brightness, are used to minimize energy consumption during idle periods or low-usage scenarios. For example, interactive whiteboards may dim their displays automatically when not in use, while coding robots enter deep sleep mode after a period of inactivity to extend battery life. PCBs optimize power distribution networks (PDNs) to reduce voltage drops and improve efficiency, using thick copper traces for high-current paths and multiple decoupling capacitors to filter noise.

Battery-powered devices, such as portable language translators or field microscopes, require PCBs that balance performance with runtime. Manufacturers select lithium-polymer or lithium-iron-phosphate batteries with high energy densities and integrate battery management systems (BMS) to monitor charge levels, prevent overcharging, and extend battery lifespan. PCBs may also incorporate energy harvesting technologies, such as solar cells or piezoelectric sensors, to supplement battery power in self-sustaining devices like outdoor science sensors.

Sustainability is increasingly important in educational equipment, with PCBs designed to reduce electronic waste through modular architectures and recyclable materials. For example, some PCBs use lead-free solder and halogen-free laminates to comply with environmental regulations like RoHS and WEEE. Modular designs allow individual components, such as sensors or communication modules, to be replaced without discarding the entire PCB, extending the device’s useful life. Manufacturers also collaborate with educational institutions to implement take-back programs for end-of-life equipment, ensuring responsible disposal or recycling of PCBs.

By addressing connectivity, durability, and power efficiency, PCB manufacturers can create educational equipment that supports dynamic, inclusive, and sustainable learning environments. These functional requirements ensure that devices remain reliable, safe, and cost-effective, empowering educators and students to focus on innovation and discovery.