In the modern industrial landscape, the importance of reliable, efficient, and durable manufacturing systems cannot be overstated. As industries become more dependent on automation, robotics, and electronic control systems, Printed Circuit Board (PCB) Assembly has emerged as a critical component in ensuring the seamless functioning of complex machinery. Industrial PCB assembly plays a vital role in manufacturing systems by providing the backbone for various electronic components, from sensors and actuators to controllers and communication systems.

What is PCB Assembly?

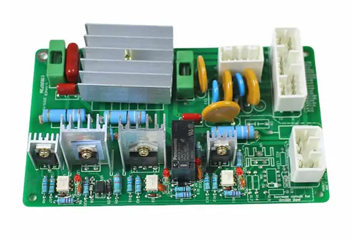

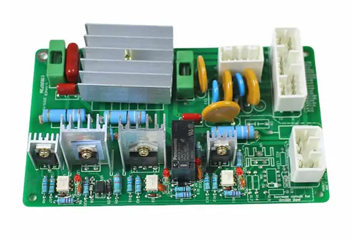

Before delving into the specific benefits and applications, it's essential to understand what PCB assembly involves. PCB assembly (PCBA) refers to the process of mounting electronic components onto a printed circuit board (PCB) to create a functional electronic circuit. The process involves several steps, including component placement, soldering, and testing, to ensure that the assembled PCB meets the desired performance standards.

PCBs themselves are thin, flat boards made from insulating materials such as fiberglass, with conductive copper tracks that link various components. These components may include resistors, capacitors, microchips, sensors, and more, depending on the specific application. Once the components are mounted and soldered onto the PCB, the board is tested for functionality to ensure that it operates correctly.

The Role of PCB Assembly in Industrial Applications

In industrial settings, PCBs are widely used to support a vast range of equipment and machinery, including control systems, sensors, power supplies, robotics, and much more. Industrial PCB assemblies are designed to withstand harsh operating environments, including high temperatures, vibrations, and electromagnetic interference. Below, we’ll discuss the crucial role that PCB assembly plays in industrial applications:

1. Enhanced Durability for Industrial Equipment

Durability is one of the key requirements for industrial applications, as equipment is often exposed to extreme conditions. Manufacturing systems, especially in industries like automotive, aerospace, and heavy machinery, need to function reliably in environments where they face constant wear and tear. Industrial PCB assemblies are designed with materials that can resist extreme temperatures, moisture, dust, and other environmental factors that can affect performance.

The assembly process also ensures that the components are firmly secured, reducing the risk of malfunction or damage due to vibration or movement. This durability minimizes downtime, leading to higher productivity and lower maintenance costs for industrial operations.

2. Optimizing Performance and Efficiency

The performance of industrial machinery depends heavily on the quality and reliability of the PCB assembly. In industrial applications, PCBs are used in various control systems that drive processes, manage production lines, and automate operations. A high-quality PCB assembly ensures that these systems function optimally, reducing errors and improving overall efficiency.

For example, in automated manufacturing lines, the control systems driven by PCBs regulate the movement of parts, synchronize robotic arms, and ensure accurate product assembly. The efficiency of these systems directly impacts production speeds, quality control, and operational costs. By using well-designed PCBs, manufacturers can improve both the speed and accuracy of their operations, leading to increased output and reduced waste.

3. Compact Design for Space-Saving Solutions

Many industrial systems require compact, space-saving designs to maximize available real estate in manufacturing plants. PCB assemblies provide an ideal solution by integrating numerous electronic components into a small, flat surface. This compactness allows manufacturers to reduce the size of their equipment, enabling more efficient use of space.

For example, robotics and automated machines rely on compact PCBs to ensure that all necessary components are housed in a small footprint without compromising performance. By utilizing industrial PCBs, manufacturers can create high-performance, space-efficient machinery that fits within the constraints of modern production facilities.

4. Improved Precision and Control

Precision and control are critical in many industrial sectors, including robotics, automotive, and aerospace manufacturing. PCB assemblies ensure that control systems operate with the utmost accuracy, providing fine-tuned performance in processes like material handling, automated assembly, and quality control checks.

In industrial robots, for instance, PCBs are used to control actuators and sensors that guide the movement of robotic arms. These systems rely on precise PCB assemblies to ensure smooth, accurate operations, preventing errors and improving overall production quality.

Advantages of Industrial PCB Assembly

1. Customization

One of the primary benefits of PCB assembly is its ability to be customized according to the specific needs of industrial applications. Manufacturers can design PCBs that cater to particular functionality requirements, ensuring that the assembled circuit board meets the exact needs of the equipment it will be integrated into. This level of customization enhances the overall efficiency and performance of industrial systems.

2. Reliability and Redundancy

Reliability is paramount in industrial environments, where a failure in one system can have far-reaching consequences. PCB assembly offers the flexibility to incorporate redundancy features, such as multiple power sources or backup communication paths, to ensure that the equipment continues to function even if one component fails. By utilizing reliable PCB designs, manufacturers can build more resilient systems that withstand failures and continue to operate without significant disruptions.

3. Improved Connectivity

Industrial PCB assemblies often include communication interfaces such as Ethernet, Bluetooth, or wireless modules, enabling connectivity between different parts of the manufacturing system. This is crucial for modern industrial applications that require constant communication between machines, sensors, and control systems. Through advanced PCB designs, manufacturers can create connected systems that offer real-time monitoring, remote control, and data sharing, enhancing operational efficiency and reducing the need for manual intervention.

4. Reduced Component Count

By consolidating numerous components into a single PCB, manufacturers can reduce the overall component count in industrial systems. This reduction in components simplifies the design and assembly process, leading to cost savings and a more streamlined production process.

Applications of Industrial PCB Assembly

Industrial PCB assemblies are used across a variety of applications within manufacturing systems. Here are some common examples:

Robotics: PCBs are integral to controlling robots in manufacturing lines, managing movements, sensors, and feedback loops.

Control Systems: PCBs are used in the control panels of machines, providing feedback from sensors and controlling the operation of mechanical components.

Power Supplies: Many industrial applications require stable, reliable power, and PCBs are used in power supply units to convert and regulate electrical signals.

Sensors: Industrial sensors that detect temperature, pressure, vibration, or motion rely on PCBs to process and communicate their data.

Communication Equipment: Industrial communication systems rely on PCBs to manage data transmission between devices, whether through wired or wireless connections.

Conclusion

Industrial PCB assembly is essential for ensuring the performance, durability, and reliability of manufacturing systems. By providing robust, efficient, and customizable solutions, PCBs enable manufacturers to build high-quality equipment that can withstand harsh environments, boost production speeds, and maintain smooth operations. As industrial applications become increasingly complex, the role of reliable PCB assembly becomes even more critical.

Investing in industrial PCB assembly is a vital step toward improving operational efficiency, reducing maintenance costs, and achieving long-term success in manufacturing. As industries continue to evolve, PCB assembly will remain at the heart of advancing manufacturing technologies.

For those seeking high-quality industrial PCB assembly solutions, Shenzhen Xindachang Technology Co., Ltd. offers expertise in providing durable, efficient, and customized PCB assemblies for a wide range of industrial applications. Discover how their reliable and advanced PCB solutions can enhance your manufacturing processes. Visit www.xdcpcba.com or contact them today to learn more about their offerings and how they can help your business thrive.