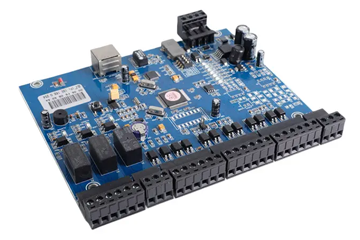

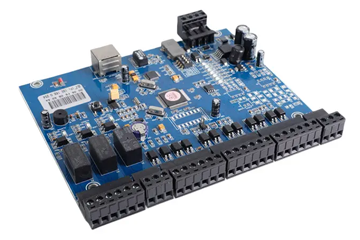

Smart Control Implementation in Air Conditioner PCB Assembly: Key Technologies and Design Considerations

The integration of smart control systems into air conditioner PCB assemblies has transformed how users interact with climate control devices, enabling features like remote operation, energy optimization, and adaptive comfort. This evolution relies on advancements in sensor technology, embedded processing, wireless communication, and machine learning algorithms. Below, we explore the technical components and design strategies essential for implementing intelligent control in air conditioner PCBs, focusing on hardware-software co-design and system reliability.

1. Advanced Sensor Integration for Real-Time Environmental Monitoring

Smart air conditioners depend on multi-parameter sensor arrays to capture data beyond basic temperature readings. High-precision thermistors or RTDs (Resistance Temperature Detectors) provide accurate ambient temperature measurements, while humidity sensors—often capacitive or resistive types—monitor relative humidity levels. The PCB must incorporate signal conditioning circuits, such as low-noise amplifiers and filters, to ensure sensor outputs remain stable despite electromagnetic interference from power electronics or motor drivers.

Indoor air quality (IAQ) sensors are increasingly critical, detecting pollutants like volatile organic compounds (VOCs), carbon dioxide (CO2), or particulate matter (PM2.5/PM10). These sensors typically use metal oxide semiconductor (MOS) or infrared absorption technologies, requiring the PCB to include calibration routines and compensation algorithms to account for environmental factors like temperature drift. For outdoor units, pressure sensors measure refrigerant line pressure, enabling the system to detect leaks or optimize compressor performance through real-time feedback loops.

Occupancy detection is another emerging feature, with PCBs integrating passive infrared (PIR) sensors or microwave Doppler radar to identify human presence. These sensors demand careful PCB layout to avoid false triggers from moving curtains or pets, often using directional shielding or machine learning-based filtering in the embedded firmware. Combining occupancy data with temperature and humidity readings allows the air conditioner to adjust cooling/heating output dynamically, reducing energy waste in unoccupied spaces.

2. Embedded Processing and Control Algorithm Optimization

The microcontroller (MCU) or system-on-chip (SoC) serves as the brain of the smart air conditioner PCB, executing control algorithms that interpret sensor data and drive actuators like compressors, fans, and expansion valves. Modern designs favor 32-bit MCUs with floating-point units (FPUs) to handle complex calculations required by PID (Proportional-Integral-Derivative) controllers or model predictive control (MPC) frameworks. The PCB must allocate sufficient flash memory for algorithm storage and RAM for real-time data processing, with bootloader support for over-the-air (OTA) firmware updates to enhance functionality post-deployment.

Machine learning (ML) integration is transforming control strategies, enabling adaptive behavior based on historical usage patterns. For example, an on-device neural network can analyze time-of-day temperature preferences, occupancy schedules, and external weather forecasts to pre-cool or pre-heat spaces before user arrival. The PCB requires a dedicated ML accelerator or optimized libraries for low-power inference, balancing computational load with thermal constraints imposed by the air conditioner’s enclosed environment.

Fault diagnosis and self-healing mechanisms are equally vital. The MCU can monitor sensor health through checksum validation and compare readings against expected ranges to detect failures. For actuator issues, such as a stuck compressor or blocked fan, the PCB may implement current sensing circuits to measure motor load, triggering alerts or safe shutdown protocols. Advanced designs use digital twins—virtual replicas of the physical system—to simulate fault scenarios and validate corrective actions before deployment.

3. Wireless Connectivity and Cloud Integration for Enhanced Usability

Smart air conditioners rely on wireless protocols like Wi-Fi, Bluetooth Low Energy (BLE), or Zigbee to connect with user interfaces, mobile apps, and cloud platforms. The PCB must include RF front-end modules (FEMs) with power amplifiers (PAs) and low-noise amplifiers (LNAs) to ensure reliable communication over varying distances and through obstacles like walls. Antenna design is critical, with PCB traces often shaped as inverted-F antennas (IFAs) or meandered monopoles to optimize radiation patterns while minimizing space usage.

Cloud integration enables remote control, energy analytics, and firmware updates. The PCB’s communication stack must support secure protocols like TLS/SSL for data encryption and OAuth for authentication, protecting user privacy from cyber threats. Cloud platforms can aggregate data from multiple units to identify regional efficiency trends or predict maintenance needs, with the PCB transmitting diagnostic logs at regular intervals or upon trigger events like error codes.

Voice assistant compatibility adds convenience, requiring the PCB to interface with microphones for wake-word detection or integrate off-the-shelf voice modules. For global markets, the design must accommodate regional differences in wireless regulations (e.g., FCC in the U.S., ETSI in Europe) and language support for voice commands, often achieved through modular firmware architectures or configurable hardware pins.

4. Power Management and Thermal Design for System Reliability

Efficient power distribution is essential to minimize energy losses and heat generation within the PCB. Switching regulators (buck/boost converters) are preferred over linear regulators for stepping down voltages to power-sensitive components like the MCU or wireless module, as they offer higher efficiency at varying loads. The PCB layout must separate high-current paths (e.g., compressor control) from low-voltage signal traces to prevent crosstalk, with thermal vias transferring heat from hot components to copper planes or heatsinks.

Battery backup or supercapacitors provide temporary power during outages, ensuring the system retains settings and completes safe shutdown sequences. For inverter-based air conditioners, which adjust compressor speed for variable cooling capacity, the PCB must include insulated-gate bipolar transistors (IGBTs) or silicon carbide (SiC) MOSFETs for high-frequency switching, with gate drivers featuring desaturation detection to protect against short circuits.

Thermal management extends to sensor placement, as inaccurate readings from overheated components can degrade control performance. The PCB may incorporate NTC thermistors to monitor its own temperature, triggering fan speed adjustments or derating compressor output if thresholds are exceeded. Conformal coatings or potting compounds protect against moisture and dust, particularly in outdoor units exposed to harsh weather, while EMI shielding ensures wireless communication remains stable despite interference from motor noise.

5. Human-Machine Interface (HMI) Design for Intuitive Interaction

Smart air conditioners feature intuitive HMIs that blend physical controls with digital displays. Capacitive touch panels or membrane switches provide tactile feedback for temperature adjustment or mode selection, with the PCB decoding inputs through a touch controller IC or GPIO pins. For displays, monochrome LCDs suffice for basic information, while full-color TFT screens enable rich visualizations of energy usage, IAQ metrics, or weather forecasts.

Haptic feedback enhances usability, with the PCB driving vibration motors to confirm button presses or alert users to maintenance reminders. Backlighting or RGB LEDs indicate operational states (e.g., cooling, heating, standby), with brightness adjustable via ambient light sensors to avoid glare at night. Accessibility features like voice navigation or large-font modes cater to users with visual impairments, requiring the PCB to support multi-language audio prompts or scalable UI frameworks.

In commercial settings, the PCB may integrate with building management systems (BMS) via Modbus or BACnet protocols, enabling centralized control of multiple units from a single dashboard. For smart home ecosystems, compatibility with protocols like MQTT or Apple HomeKit ensures seamless interoperability with other devices, such as smart thermostats or window sensors, to create cohesive climate control strategies.

6. Cybersecurity Measures to Protect Against Emerging Threats

As air conditioners become connected devices, they face risks like unauthorized access, data theft, or ransomware attacks. The PCB must implement hardware-based security features, such as secure boot to verify firmware integrity during startup and cryptographic accelerators for fast encryption/decryption of communication packets. Trusted Platform Modules (TPMs) or secure elements store encryption keys and credentials, isolating them from the main MCU to prevent extraction via software exploits.

Firmware updates must be signed and authenticated before installation, with the PCB checking digital signatures against a root of trust stored in read-only memory (ROM). Network traffic should use mutual TLS (mTLS) for device-to-cloud authentication, ensuring only authorized servers can communicate with the air conditioner. Regular security audits and penetration testing help identify vulnerabilities, with patches distributed via OTA updates to maintain protection against evolving threats.

User data privacy is equally critical. The PCB should minimize data collection to essential metrics (e.g., temperature settings, energy usage) and anonymize logs before transmission to the cloud. Local storage options, such as encrypted eMMC or NOR flash, allow users to retain control over their data, with the PCB providing options to disable cloud sync entirely for offline operation.

Conclusion

The smart control implementation in air conditioner PCB assemblies represents a convergence of electronics, software, and connectivity technologies. By prioritizing sensor accuracy, adaptive algorithms, secure communication, and user-centric design, manufacturers can create systems that deliver energy efficiency, comfort, and convenience. As AI and IoT technologies continue to advance, future PCB designs will likely incorporate edge computing for real-time decision-making and deeper integration with renewable energy sources, further reducing the environmental impact of climate control systems.