The rapid advancement of technology has brought about the rise of the Internet of Things (IoT), a revolutionary concept that connects everyday devices to the internet and enables them to collect, share, and exchange data. The IoT has significantly transformed numerous industries, including healthcare, home automation, transportation, and manufacturing. One of the key enablers of the IoT revolution is the seamless integration of hardware and software, which relies heavily on printed circuit boards (PCBs). As the backbone of electronic devices, PCBs are crucial in enabling the connectivity, functionality, and performance of smart products.

The Role of IoT in Modern Technology

The Internet of Things (IoT) refers to the network of physical objects or "things" embedded with sensors, software, and other technologies that allow them to connect and exchange data with other devices and systems over the internet. From smart homes to industrial automation, IoT has become an integral part of modern technology. Its ability to create smarter, more efficient systems has made it a driving force behind innovations in various fields, including healthcare, energy management, agriculture, and urban infrastructure.

IoT technology enables devices to communicate with each other in real time, creating a more interconnected world. This connectivity allows for automation, remote monitoring, and predictive analysis, improving efficiency, reducing costs, and enhancing user experiences. For example, smart thermostats learn user preferences and adjust heating or cooling automatically, while wearable fitness trackers monitor health metrics and sync the data with smartphones for better health management.

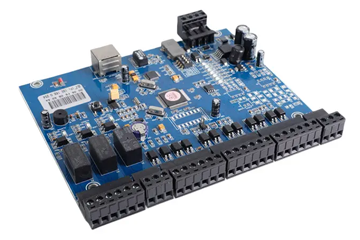

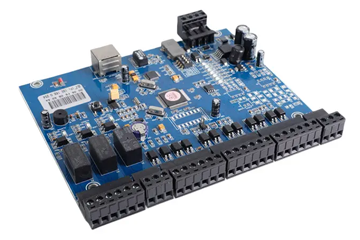

However, at the heart of every IoT device lies a fundamental component that makes this connectivity and functionality possible—the printed circuit board (PCB). PCB assemblies serve as the foundation for connecting and powering the electronic components in IoT devices, making them an essential part of the IoT ecosystem.

How PCB Assembly Powers the Connectivity and Performance of Smart Products

PCBs are critical to the operation of IoT devices because they provide the necessary electrical connections between components. A PCB is a flat board that houses electrical circuits made from conductive material, typically copper. These circuits allow components like microprocessors, sensors, and communication modules to work together seamlessly, ensuring that the device performs its intended function.

In IoT devices, PCBs are responsible for several key functions:

Data transmission: PCBs route signals between sensors, processors, and communication modules, enabling devices to transmit data to other devices or cloud-based systems.

Power distribution: PCBs deliver power to components, ensuring that the device operates efficiently without wasting energy.

Connectivity: Many IoT devices rely on wireless communication technologies such as Bluetooth, Wi-Fi, Zigbee, or cellular connectivity, all of which require PCB integration.

The complexity of PCB assemblies in IoT devices has grown with the increasing demand for smaller, more powerful, and feature-rich products. The design and assembly of PCBs for IoT devices require careful consideration of several factors, including size, energy efficiency, and the specific functionalities of the device.

PCB Assembly for IoT Devices

The functionality of IoT devices heavily depends on the quality and design of the PCBs that power them. IoT devices vary widely in terms of size, function, and application, ranging from simple sensors to sophisticated wearable devices and home automation systems. Below are some examples of IoT devices that rely on high-quality PCB assemblies:

Smart Homes

In smart homes, IoT devices include lighting systems, security cameras, smart locks, thermostats, and appliances. Each of these devices requires a well-designed PCB assembly to ensure that they function as intended. For example, a smart thermostat PCB assembly integrates sensors to monitor room temperature, a microcontroller to process the data, and communication modules to connect to Wi-Fi or Bluetooth networks, allowing users to control the system remotely via a smartphone app.

Wearables

Wearable devices such as fitness trackers, smartwatches, and health monitors rely on miniaturized PCBs to fit into compact, lightweight designs. These devices often include sensors that monitor heart rate, sleep patterns, steps taken, and other health metrics. The PCB assembly in wearables must support efficient data processing and communication with other devices while maintaining energy efficiency to prolong battery life.

Connected Appliances

IoT-enabled home appliances, such as refrigerators, washing machines, and ovens, allow users to control and monitor these devices remotely. The PCB assemblies in these devices handle data collection (e.g., temperature and motion sensors), control functions (e.g., adjusting settings or notifications), and communication (e.g., connecting to the internet via Wi-Fi or Bluetooth). These devices improve user convenience, energy management, and operational efficiency.

Ensuring Reliable Data Transmission and Energy Efficiency in IoT Devices

Reliable data transmission and energy efficiency are critical for the success of IoT devices. Since many IoT devices are designed to operate autonomously and rely on wireless communication, ensuring the integrity of data transmission is paramount. In addition, energy efficiency is essential, especially for battery-operated devices like wearables and remote sensors that need to function for extended periods without frequent recharging.

Reliable Data Transmission

PCBs in IoT devices must be designed to handle high-speed data transmission with minimal latency. This requires the integration of high-quality components, such as communication modules (Wi-Fi, Bluetooth, Zigbee) and signal processing circuits, into the PCB assembly. A well-designed PCB ensures that data can flow seamlessly between the device and external systems, such as smartphones or cloud-based platforms.

Moreover, the increasing reliance on wireless communication technologies means that PCB assemblies must be optimized to reduce interference and noise. Techniques such as careful placement of components, shielding, and grounding are used to ensure that the PCB assembly supports high-performance data transmission in the presence of potential electromagnetic interference (EMI).

Energy Efficiency

Since many IoT devices are powered by batteries or low-power sources, energy efficiency is a key consideration during PCB assembly. Power management systems integrated into the PCB help optimize energy consumption by controlling the flow of power to different components based on the device's operating needs. This is particularly important for battery-operated IoT devices, as efficient power management can extend battery life and reduce the frequency of recharging.

Low-power communication technologies, such as Zigbee or Bluetooth Low Energy (BLE), are often used in IoT devices to minimize power consumption. PCBs in these devices are designed to support these energy-efficient communication protocols, allowing devices to operate longer on a single charge while still maintaining reliable connectivity.

Design Challenges in IoT PCB Assembly

Designing PCBs for IoT devices comes with several unique challenges. These challenges stem from the need to create compact, energy-efficient, and reliable circuits that fit within the form factors and performance requirements of IoT applications.

Miniaturization

Many IoT devices, such as wearables and smart sensors, must be compact and lightweight to be practical and comfortable for users. Achieving miniaturization in PCB assembly requires careful component selection and placement, as well as the use of advanced manufacturing techniques like surface-mount technology (SMT) to reduce the size of the components. Miniaturization also presents challenges in terms of signal integrity and heat dissipation, as tightly packed components can interfere with each other and generate excess heat.

Power Efficiency

Power consumption is a critical consideration in IoT design, particularly for battery-operated devices. Engineers must design the PCB to manage power effectively, using low-power components and optimizing the circuit layout to minimize energy waste. Additionally, power management circuits, such as voltage regulators and battery chargers, are integrated into the PCB to ensure that the device operates within the power constraints of its environment.

Wireless Connectivity

Wireless connectivity is a key feature of IoT devices, and designing PCBs to support technologies like Wi-Fi, Bluetooth, Zigbee, and cellular connectivity requires a deep understanding of RF (radio frequency) design. The PCB layout must be optimized to reduce signal interference and ensure strong, stable connections. Additionally, antennas must be carefully integrated into the PCB to achieve the best possible range and performance.

Key Components in IoT PCB Assembly

The success of IoT devices largely depends on the integration of key components into the PCB assembly. These components enable the device to function as intended, providing features such as sensing, data processing, and communication.

Sensors

Sensors are a fundamental component of IoT devices. They detect environmental conditions such as temperature, humidity, pressure, motion, and light. The data collected by sensors is transmitted to the device’s microprocessor, where it is processed and used to trigger specific actions, such as adjusting a thermostat or sending an alert to the user.

Processors

The processor, or microcontroller, is the brain of the IoT device. It processes data from sensors, executes instructions, and controls the device’s functions. Processors in IoT devices need to be efficient and powerful enough to handle multiple tasks while maintaining low power consumption.

Communication Modules

Communication modules, such as Wi-Fi, Bluetooth, Zigbee, and cellular, enable IoT devices to connect to the internet and communicate with other devices. The PCB assembly must support the integration of these modules to ensure reliable data transfer and connectivity.

Power Management Systems

Power management is essential in IoT devices, particularly for battery-operated products. Power management circuits are integrated into the PCB to regulate voltage levels, manage battery charging, and optimize energy usage. Efficient power management ensures that the device operates for extended periods without the need for frequent recharging.

Security and Reliability Considerations

With the increasing number of IoT devices in use, security and reliability have become top concerns. IoT devices often collect and transmit sensitive data, making them vulnerable to cyber-attacks and privacy breaches.

Data Protection

PCB assembly plays a crucial role in securing IoT devices by incorporating encryption and security features into the device's hardware. Secure elements, such as trusted platform modules (TPM) or hardware security modules (HSM), can be integrated into the PCB to protect data and ensure secure communication between devices.

Addressing Vulnerabilities

IoT devices are often targeted by hackers due to their interconnected nature and limited security measures. To mitigate these risks, manufacturers must incorporate security features at the PCB level, such as secure boot processes, firmware updates, and robust authentication protocols. Additionally, regular security patches and updates should be implemented to address newly discovered vulnerabilities.

Future Trends in IoT PCB Assembly

The future of IoT is closely tied to advancements in technology, and PCB assembly will continue to evolve to support emerging trends. Here are some key trends to watch in the coming years:

5G Integration

The rollout of 5G networks will revolutionize IoT by enabling faster data transmission and improved connectivity. PCBs in IoT devices will need to support 5G modules to handle the increased bandwidth and speed requirements of next-generation IoT applications.

Artificial Intelligence (AI)

AI is expected to play a significant role in IoT devices, allowing for smarter, more autonomous devices. PCBs will need to integrate AI chips and processors to enable devices to process and analyze data locally, improving response times and reducing the reliance on cloud computing.

Increased Demand for Connected Devices

As IoT continues to expand, the demand for connected devices in industries like healthcare, home automation, and industrial IoT (IIoT) will grow. PCB assembly will need to accommodate the increasing complexity and functionality of these devices while maintaining energy efficiency and reliability.

Conclusion

IoT devices are revolutionizing how we interact with technology in our everyday lives, bringing smarter solutions to homes, workplaces, and industries. At the core of these devices is the printed circuit board (PCB), which ensures the connectivity, functionality, and performance that make IoT possible. As IoT technology continues to advance, the importance of reliable PCB assembly will remain essential in driving the development of innovative and efficient devices.

At Shenzhen Xindachang Technology Co., Ltd., we specialize in providing high-quality PCB assembly services for IoT devices, ensuring performance, reliability, and security. Our expertise in addressing challenges like miniaturization, power efficiency, and data protection allows us to deliver cutting-edge solutions for a wide range of connected products.

To learn more about how we can help enhance your IoT devices with precision PCB assembly, visit www.xdcpcba.com or contact us today. Our team is ready to support your next IoT project with the latest in PCB technology.