Limitations and Challenges of AOI Inspection Technology in PCB and PCBA: In-depth Analysis and Future Outlook

In the rapid development of the electronic information industry, PCB (printed circuit board) and PCBA (printed circuit board assembly) are the core components of electronic equipment, and their quality directly determines the performance and reliability of the entire product. AOI (automatic optical inspection) technology is an indispensable part of the PCB and PCBA production process. Through high-precision image capture and intelligent analysis, it effectively improves product quality and production efficiency. However, AOI technology is not omnipotent in practical applications, and its limitations and challenges cannot be ignored. This article will explore the limitations and challenges of AOI inspection technology in PCB and PCBA in depth, and introduce the unique advantages of XDCPCBA as a professional PCB and PCBA manufacturer at the end of the article.

1. Limitations of AOI inspection technology in PCB and PCBA

Limitations of detection accuracy and resolution

The detection accuracy and resolution of AOI technology are one of its core performance indicators, but due to the current technical level, the AOI system may not be able to accurately capture minor defects in some cases. For example, for minor problems such as minor scratches on PCBs, copper foil warping, or component pin bending in PCBAs, the AOI system may miss detection due to insufficient resolution. In addition, as the integration of PCB and PCBA continues to increase and the size of components continues to shrink, higher requirements are placed on the detection accuracy of AOI systems.

Difficulty of detection under complex backgrounds

The production process of PCB and PCBA is often accompanied by complex background environments, such as components and solder joints of various colors, textures and shapes. These complex backgrounds may interfere with the image capture and analysis of the AOI system, resulting in false alarms or missed alarms. Especially in the detection of high-density, multi-layer PCBs and complex PCBAs, the AOI system requires higher image processing capabilities to accurately identify target defects.

Detection blind spots for specific types of defects

AOI technology mainly relies on image capture and analysis. For certain specific types of defects, such as defects of parts or components hidden under the edge of solder joints, internal cracks or bubbles, the AOI system may not be able to accurately detect them. These defects often need to be supplemented by other detection methods, such as X-ray detection, ultrasonic detection, etc.

Influence of lighting and angles

The detection effect of AOI technology is greatly affected by lighting conditions and shooting angles. In the case of insufficient lighting or improper angles, the AOI system may not be able to clearly capture the detailed information of the components, thus affecting the accuracy of the detection results. Therefore, in practical applications, it is necessary to strictly control the lighting conditions and shooting angles to ensure the detection effect of the AOI system.

Limitations of algorithms and software

The core of AOI technology lies in image processing and analysis algorithms. However, the current algorithms and software still have some limitations, such as processing speed, recognition accuracy and adaptability. Especially when facing complex and changeable PCB and PCBA products, the AOI system needs to continuously upgrade and optimize the algorithm to adapt to new detection needs.

2. Challenges of AOI detection technology in PCB and PCBA

Technology update and iteration speed

With the rapid development of electronic information technology, the integration and complexity of PCB and PCBA are constantly improving, and the requirements for AOI technology are also getting higher and higher. The AOI system needs to be continuously upgraded and optimized to adapt to new detection needs and challenges. However, the speed of technology update and iteration is often faster than the research and development speed of AOI system, resulting in lag in some aspects of AOI technology.

Cost control and efficiency improvement

Although the introduction of AOI technology has improved the production efficiency and product quality of PCB and PCBA, it has also increased production costs. How to reduce the cost of AOI technology and improve production efficiency while ensuring the quality of inspection is a major challenge facing AOI technology at present. In addition, with the intensification of market competition, customers' requirements for delivery time are getting shorter and shorter, and AOI systems need to have higher inspection speed and efficiency to meet customers' urgent needs.

Talent training and team building

The research and development and application of AOI technology require professional technical talents and team support. However, talents with AOI technical background in the current market are relatively scarce, and the training cost is high. Therefore, how to cultivate and introduce AOI technical talents and build a professional R&D team is one of the key factors in the development of AOI technology.

Cross-field cooperation and technological innovation

The development of AOI technology needs to be integrated and innovated with technologies in other fields. For example, cooperation with machine vision, artificial intelligence, big data and other fields can promote the intelligence and automation level of AOI technology. However, cross-field cooperation needs to overcome technical barriers, communication barriers and interest distribution, and requires joint efforts and collaboration from all parties.

3. XDCPCBA: Unique advantages of professional PCB and PCBA manufacturers

When discussing the limitations and challenges of AOI inspection technology in PCB and PCBA, we have to mention XDCPCBA, a professional PCB and PCBA manufacturer. XDCPCBA is unique in the field of electronic manufacturing with its strong production strength, profound industry experience and professional AOI inspection system.

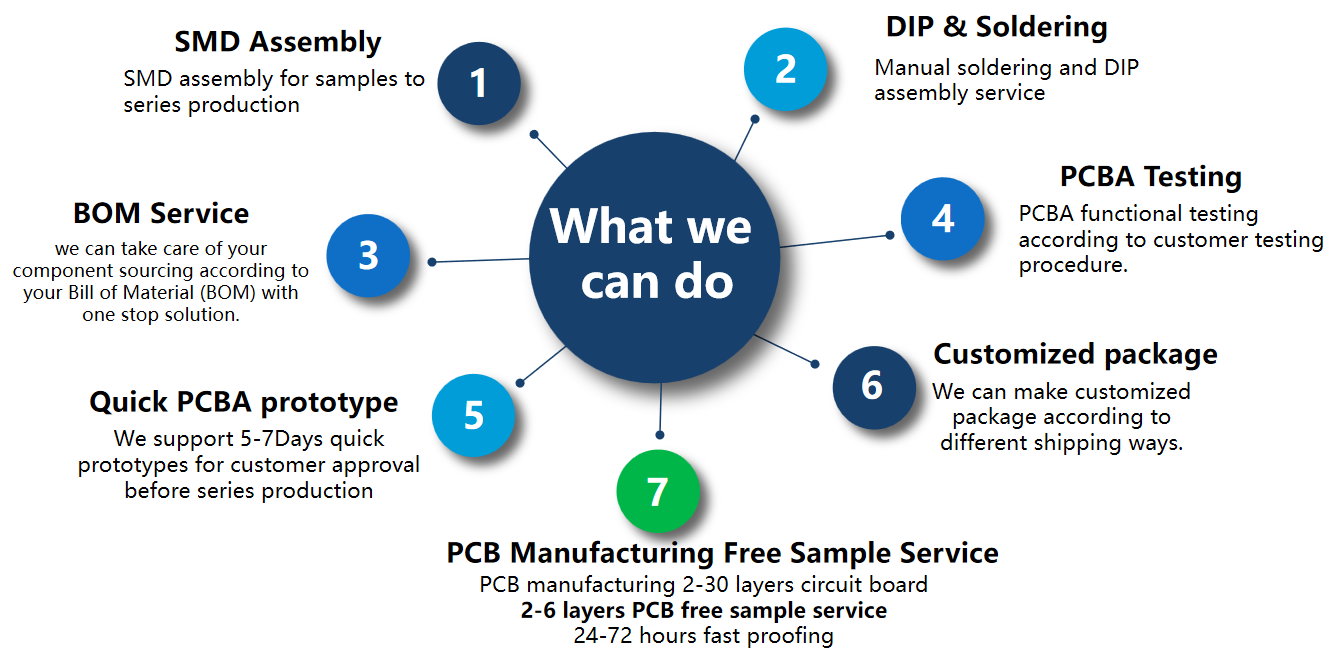

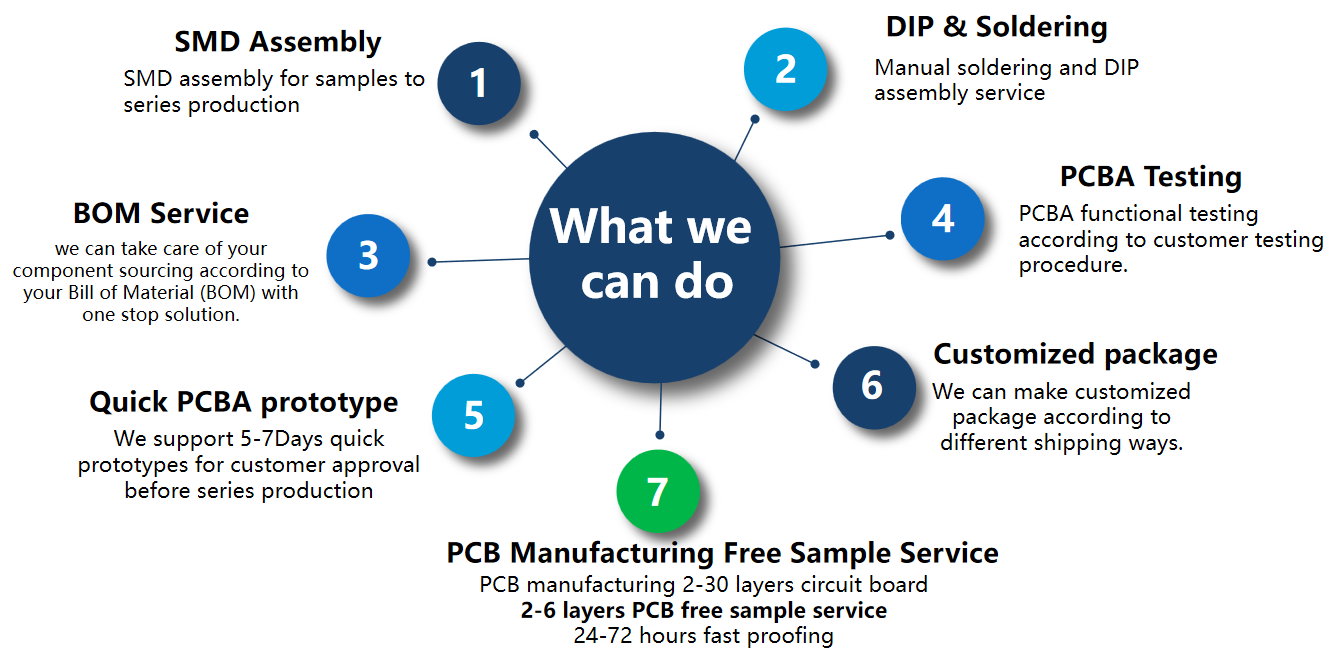

Strong production capacity: XDCPCBA has the production capacity of 2-30 layers of PCB, which can meet the diverse needs of different customers. Its advanced production equipment and process flow ensure the high quality and high efficiency of PCB production.

Professional AOI inspection system: XDCPCBA is equipped with advanced AOI inspection systems, which can perform comprehensive automated inspection of PCBA. These systems use the latest image processing algorithms and inspection technologies, which can accurately identify various defects and ensure the reliability and stability of products. At the same time, XDCPCBA continues to upgrade and optimize the AOI system to adapt to new inspection needs and challenges.

Free sample service: In order to help customers better understand XDCPCBA's production capacity and product quality, the company has launched a 2-6 layer PCB free sample service. Customers can get high-quality PCB samples through this service, so that they can trust XDCPCBA's products and services more.

Comprehensive PCBA processing services: In addition to PCB production, XDCPCBA also provides comprehensive PCBA processing services. From component procurement, mounting, welding to testing, assembly and other links, XDCPCBA can provide professional technical support and services to ensure that customers' products can be produced on time, in quality and in quantity.

Deep customer understanding: XDCPCBA is well aware of the importance of customer needs. Therefore, the company always puts customer needs first and is committed to providing customers with the best products and services. Whether it is product design, production process or after-sales service, XDCPCBA can customize and optimize according to the actual needs of customers.

In summary, although AOI detection technology in PCB and PCBA has significant advantages, there are still some limitations and challenges. However, with the continuous advancement of technology and the continuous expansion of application scenarios, AOI technology will play a more important role in the electronics manufacturing industry. At the same time, as a professional PCB and PCBA manufacturer, XDCPCBA provides customers with high-quality and efficient electronic manufacturing solutions with its strong production strength, professional AOI detection system and comprehensive processing services. In the future, XDCPCBA will continue to be committed to technological innovation and quality improvement, and contribute more to the development of the electronics manufacturing industry.