Design of low-cost smart door lock solution: PCB layer selection and component layout optimization

In today's smart home market, smart door locks have received widespread attention for their convenience and security. In order to create an economical and efficient smart door lock, the selection of PCB (printed circuit board) layers and the optimization of component layout are particularly critical. This article will explore how to reduce the cost of smart door locks through reasonable PCB layer selection and component layout optimization. At the same time, it will introduce concepts such as XDCPCBA PCB assembly factory, PCBA processing factory, PCBA manufacturer, and electronic contract manufacturer to comprehensively analyze the design process of low-cost smart door lock solutions for you.

1. PCB layer selection: balance between cost and performance

As an important part of smart home, the choice of PCB layers of smart door locks directly determines the complexity and manufacturing cost of the circuit board. Under the premise of ensuring performance, reducing the number of PCB layers is an effective way to reduce costs.

Basic layer analysis

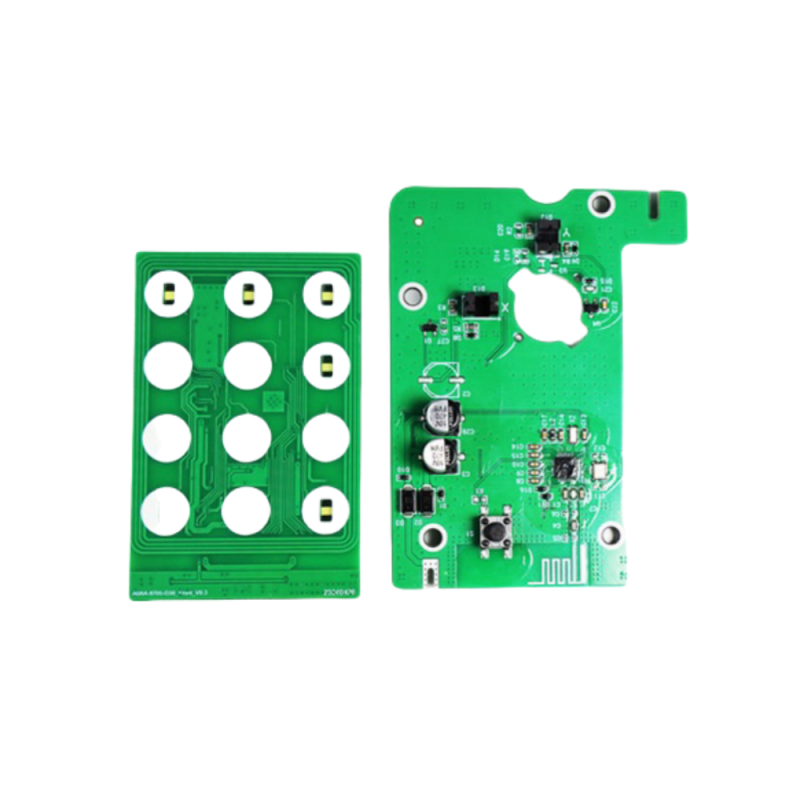

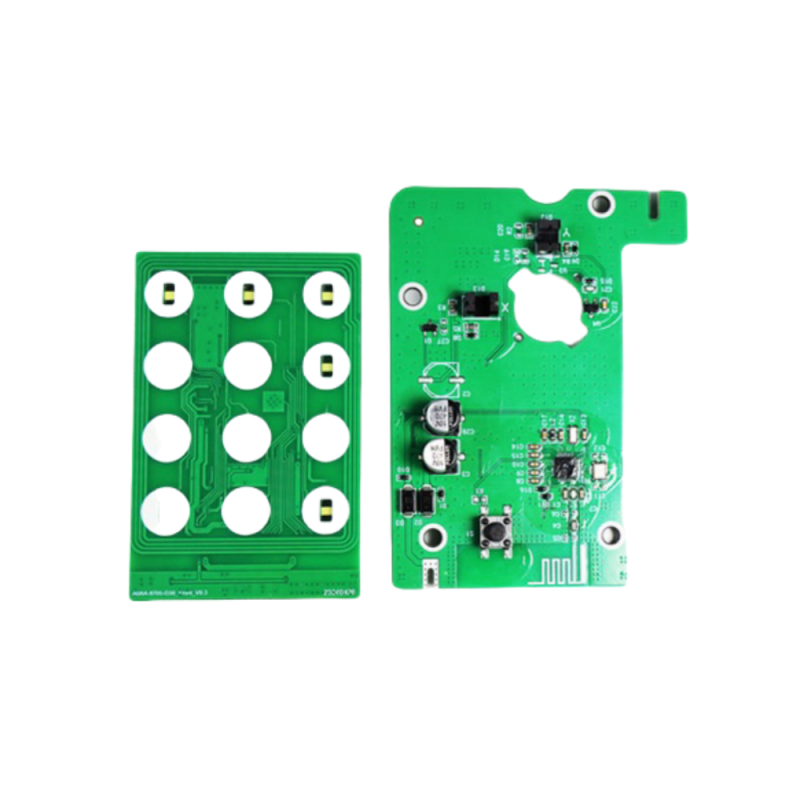

Double-layer board: Double-layer board has the characteristics of simple structure and low cost, and is suitable for scenarios with low requirements for electromagnetic compatibility. However, smart door locks usually need to integrate more electronic components and complex circuits, and double-layer boards may be difficult to meet wiring requirements.

Four-layer board: Four-layer board provides more wiring space, which is conducive to optimizing component layout and reducing electromagnetic interference. At the same time, four-layer board still has advantages in cost control and is a common choice in smart door lock design.

Multi-layer board: As the number of layers increases, the wiring capacity, electrical performance and electromagnetic compatibility of PCB will be improved, but the cost will also increase accordingly. For high-end smart door locks, PCB boards with 6 or more layers can be considered to meet higher performance requirements.

Advantages of even-layer PCBs

Even-layer PCBs have cost advantages in the manufacturing process, because odd-layer PCBs need to add non-standard laminated core layer bonding processes on the basis of core structure processes, which increases the cost and risk of outer layer processing. In addition, even-layer PCBs are easier to achieve a balanced laminated structure, which helps to reduce the bending and deformation of PCB boards.

Low-cost solution recommendations

For low-cost smart door lock solutions, four-layer PCBs are recommended. This can not only meet complex wiring requirements, but also effectively control costs. At the same time, using the professional capabilities of XDCPCBA PCB assembly factories, efficient PCB assembly and testing can be achieved, further reducing costs.

2. Component layout optimization: improving efficiency and reducing costs

Optimizing component layout is a key link in reducing the cost of smart door locks and improving production efficiency. Reasonable component layout not only helps to reduce wiring difficulty and electromagnetic interference, but also improves the reliability and manufacturability of PCB.

Functional partitioning

According to the functional requirements of smart door locks, components are divided into different functional areas, such as power management, communication module, control chip, etc. Through functional partitioning, PCB space can be used more effectively, and wiring conflicts and electromagnetic interference can be reduced.

Layout compactness

While ensuring that there is enough spacing between components to avoid short circuits and interference, try to layout components more compactly. This helps to reduce the size and weight of the PCB, thereby reducing material costs.

Special treatment of high-frequency components

For high-frequency components, such as capacitors and inductors, special attention should be paid to their layout and connection methods. High-frequency signals are very sensitive to the length and shape of wiring, so high-frequency components should be placed close to their connection points, and short and straight wiring should be used to reduce signal loss and interference.

Heat dissipation considerations

Some components in smart door locks, such as power management chips and communication modules, may generate a lot of heat. When laying out, these components should be placed in a well-ventilated location, and consider using heat sinks or heat dissipation holes to assist in heat dissipation.

Use professional tools

Use professional PCB design software to assist in component layout and routing. These software usually have powerful simulation and analysis functions, which can help designers find and solve potential problems in the design stage.

3. Introducing professional manufacturers and service providers

In the design process of low-cost smart door lock solutions, introducing professional manufacturers and service providers is the key to ensuring the smooth implementation of the solution.

XDCPCBA PCB assembly factory

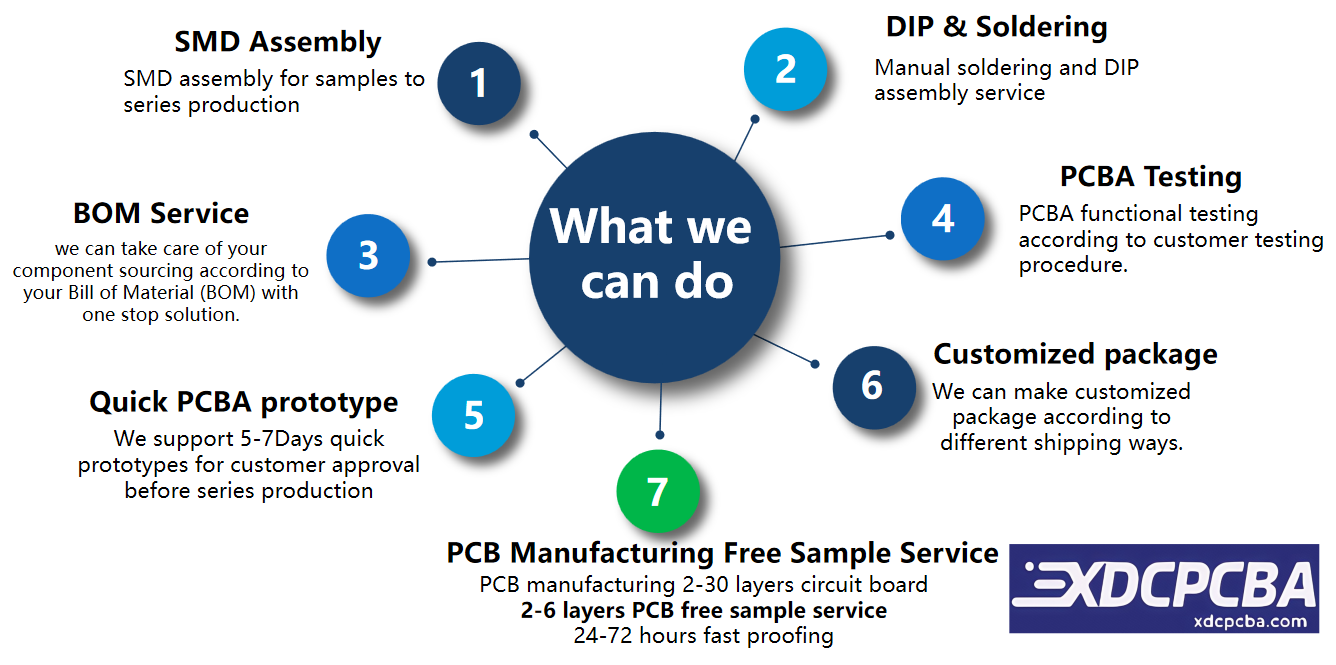

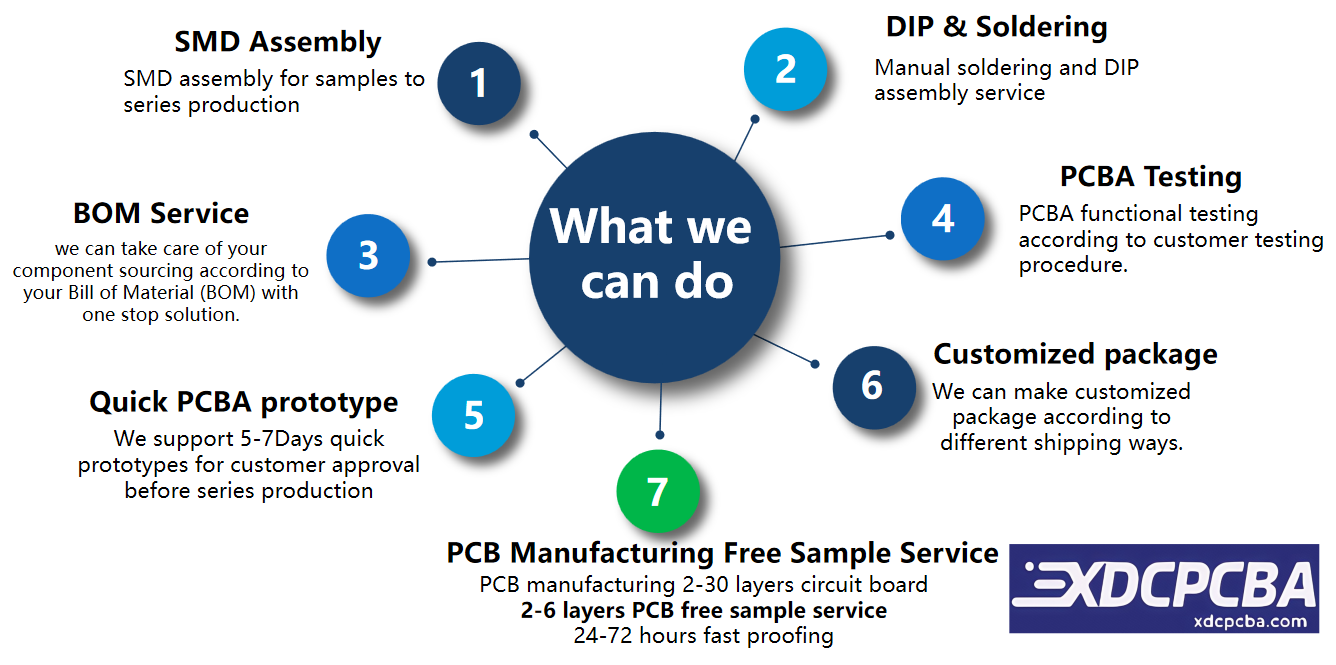

XDCPCBA PCB assembly factory has advanced production equipment and rich manufacturing experience, and can provide high-quality PCB assembly services. By working with XDCPCBA, you can ensure that the PCB assembly process of smart door locks is efficient and reliable.

PCBA processing plant

The PCBA processing plant is responsible for assembling PCB boards and electronic components into a complete circuit board assembly. Choosing a PCBA processing plant with rich experience and a good reputation can ensure the assembly quality and delivery cycle of smart door locks.

PCBA manufacturer

PCBA manufacturers not only provide PCB assembly services, but are also responsible for subsequent testing and debugging. Choosing a PCBA manufacturer with a complete industrial chain can further reduce the manufacturing cost and cycle of smart door locks.

Electronic Contract Manufacturers

Electronic contract manufacturers (OEMs) are able to provide customized smart door lock manufacturing services according to customer needs. By working with OEMs, design, manufacturing, testing and other links can be integrated to achieve efficient and low-cost smart door lock production.

SMT PCB Assembly

SMT (surface mount technology) is the mainstream method of modern electronic assembly. Through SMT technology, electronic components can be precisely mounted on the surface of the PCB to improve the density and performance of the circuit board. Choosing a manufacturer with advanced SMT equipment can ensure the assembly quality and efficiency of smart door locks.

2-30 layer PCB manufacturer

Choosing a manufacturer that can provide 2-30 layer PCB manufacturing can flexibly select the number of PCB layers according to the actual needs of smart door locks. This helps to effectively control manufacturing costs while ensuring performance.

PCB Suppliers

Choosing high-quality PCB suppliers is the basis for ensuring the smooth implementation of smart door lock solutions. High-quality PCB suppliers can provide high-quality PCB boards and professional technical support to help designers solve problems in the design process.

2-6 layer PCB free proofing service

In order to reduce the design cost, you can choose a supplier that provides 2-6 layer PCB free proofing service. Through free proofing, the feasibility and performance of the PCB can be verified in the design stage, avoiding unnecessary modifications and cost waste in the future.

In summary, through reasonable PCB layer selection and component layout optimization, combined with the support of professional manufacturers and service providers, an economical and efficient smart door lock solution can be created. The introduction of professional service providers such as XDCPCBA PCB assembly factory, PCBA processing factory, PCBA manufacturer, and electronic contract manufacturer will provide all-round support and guarantee for your smart door lock solution. In the future smart home market, low-cost, high-performance smart door locks will become the mainstream trend. We look forward to your ability to seize the opportunity and launch more excellent smart door lock products.