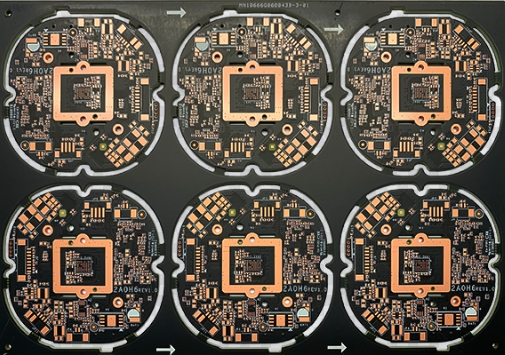

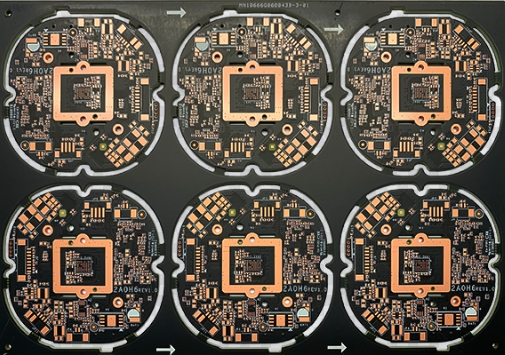

Reliable HDI PCB (High Density Interconnection Printed Circuit Board) refers to HDI PCB that takes special measures in design, material selection, manufacturing process and quality control to ensure long-term stable operation in application scenarios with high performance and high reliability requirements.

Role:

Ensure stable operation of key equipment: In the fields of medical equipment, aerospace, automotive electronics, etc., equipment failure may lead to serious consequences. Reliable HDI PCB minimizes the failure rate and ensures the stable operation of key equipment through its excellent reliability.

Improve product competitiveness: In a highly competitive market environment, product reliability is one of the key factors to win customer trust. Reliable HDI PCB can help you create more competitive products and win market share.

Reduce maintenance costs: Reliable HDI PCB can reduce equipment failures and repair times, thereby reducing maintenance costs and improving user satisfaction.

Advantages:

Longer service life: Reliable HDI PCB adopts high-quality materials and advanced processes, has a longer service life and reduces the frequency of replacement.

Higher environmental adaptability: Reliable HDI PCB can withstand harsh environments such as extreme temperature, humidity, vibration, etc., to ensure stable operation of equipment under various conditions.

Lower failure rate: Strict quality control and reliability testing ensure reliable HDI PCB with lower failure rate and reduce equipment downtime.

Our manufacturing features and advantages:

Strict material selection: We cooperate with the world's leading material suppliers to select high-quality substrates, copper foils, inks and other raw materials to ensure the reliability and performance of PCBs.

Advanced manufacturing process: We have advanced equipment and technologies such as laser drilling, vacuum lamination, fine line imaging, etc. to ensure the high precision and high reliability of HDI PCBs.

Perfect quality control system: We have established a perfect quality control system. From raw material storage to finished product shipment, each link is strictly tested to ensure that the products meet international standards and customer requirements.

Professional reliability testing: We are equipped with professional reliability testing equipment, which can perform thermal cycle testing, damp heat testing, vibration testing, etc. on HDI PCBs to ensure the reliability of products in various harsh environments.