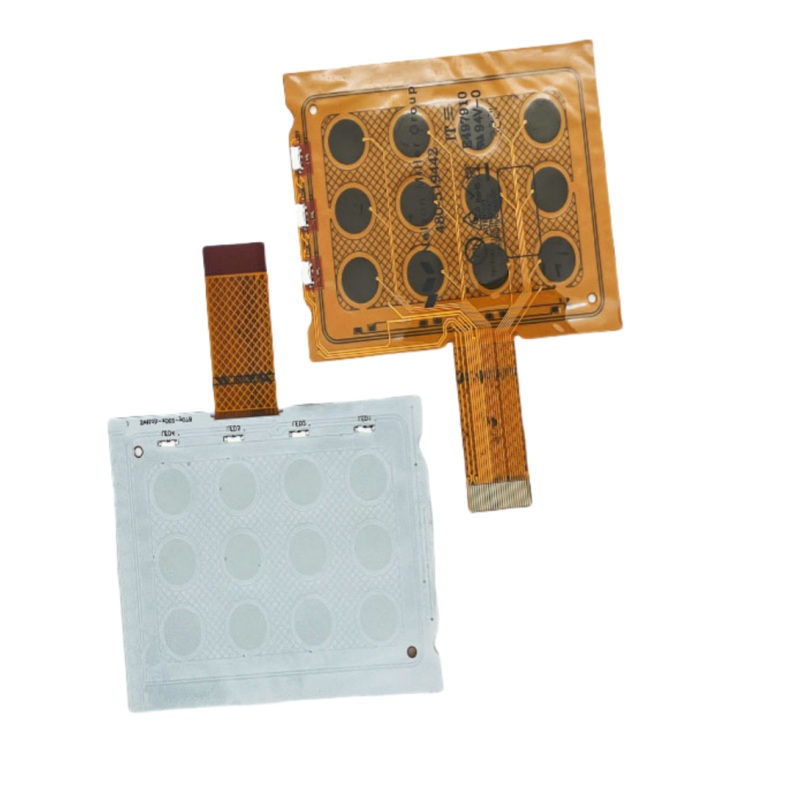

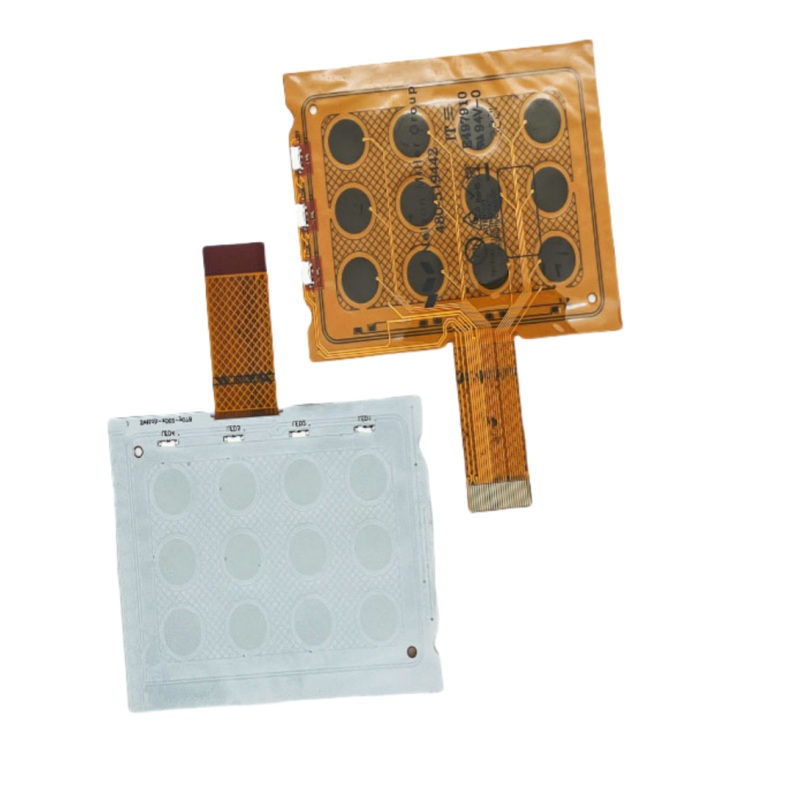

Smart door lock button FPC

In the field of smart door locks, XPCPCBA's Smart door lock button FPC has become the preferred choice for many smart door lock manufacturers due to its lightweight, high sensitivity, and high reliability. It can not only achieve fast and accurate fingerprint recognition and touch sensing, but also adapt to various complex installation environments, such as curved designs or narrow spaces. In addition, our FPC products also have excellent resistance to environmental interference, ensuring that smart door locks can operate stably under various harsh conditions.

High-Reliability FPC

XPCPCBA's High Reliability FPC, with its excellent stability and durability, has shown great potential in high-end fields such as aerospace and medical equipment. In the aerospace field, our FPC products can withstand extreme high temperatures, high pressures, and radiation environments, ensuring the stable operation of the electronic systems of aircraft. In the field of medical devices, our FPC products provide strong guarantees for precise operation of medical equipment and patient safety with their high reliability and biocompatibility.

Wearable devices: Smart watches, smart bracelets, and other wearable devices use FPC to achieve flexible connections and compact designs, improving the comfort and portability of the devices.

Smartphone: FPC is widely used in the connection of camera modules, display screens, fingerprint recognition modules, batteries and other components in smartphones, meeting design requirements such as slimness and foldability.

Tablet computer: Tablet computers use FPC to connect display screens, touch screen controls, batteries, and other components, achieving lightweight and high-performance connectivity of the device.

Smart Home: In smart home systems, FPC is widely used in devices such as smart door locks, smart control panels, and smart cameras, achieving miniaturization, intelligence, and efficient connectivity of devices. For example, the FPC in smart door locks can achieve high-precision fingerprint collection and fast recognition, improving the safety and convenience of door locks; The FPC in the intelligent control panel can achieve user identity authentication and personalized settings, enhancing the system's interactive experience.

Medical equipment: Medical devices such as electrocardiographs and portable monitors use the flexible characteristics of FPC to meet their requirements for miniaturization, portability, and high reliability. In addition, FPC has also begun to be applied in medical implant devices such as pacemakers and nerve stimulators. These devices require long-term implantation into the human body, with extremely high requirements for material biocompatibility and reliability. The flexibility and miniaturization characteristics of FPC can make implanted devices more comfortable and safe, while its high-performance connection can ensure the normal operation of the device.

Aerospace: Aerospace equipment requires lightweight and durability, and FPC can work stably in high temperature and high pressure environments, so it is widely used in satellite and aircraft electronic equipment. For example, FPCs are widely used in aircraft avionics systems, communication systems, navigation systems, etc. to improve system reliability and performance.