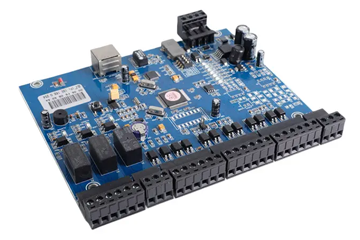

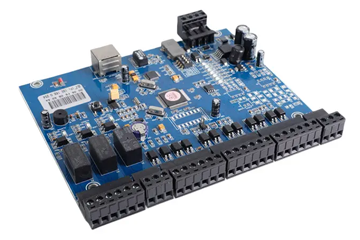

Treadmill PCB Assembly: Implementation of Motion Monitoring Circuits for Enhanced Performance Tracking

Treadmills equipped with motion monitoring circuits rely on PCB assemblies that integrate sensors, signal processing units, and connectivity modules to deliver real-time feedback on speed, distance, and workout intensity. Unlike basic models, advanced systems leverage multi-sensor fusion and embedded algorithms to improve accuracy and adaptability across diverse user profiles and running conditions. Below, we explore the key components and engineering strategies for implementing motion monitoring in treadmill PCB assemblies.

1. Sensor Integration for Precise Motion Capture

The foundation of motion monitoring lies in selecting and integrating sensors that capture linear and rotational movements with high fidelity. Hall effect sensors are commonly used to detect motor speed by measuring magnetic field variations as the motor rotates. These sensors, mounted on the PCB near the motor housing, generate pulses proportional to rotational speed, which are then converted into treadmill belt speed by the microcontroller. To minimize electromagnetic interference (EMI), the PCB layout should position Hall sensors away from high-current traces and include bypass capacitors to filter noise from the motor’s power supply.

Inertial measurement units (IMUs) combining accelerometers and gyroscopes provide additional data for stride analysis and incline detection. The PCB must support IMU modules with low-noise amplifiers (LNAs) to enhance weak signals from foot strikes or belt vibrations. For treadmills with adjustable inclines, strain gauge sensors embedded in the frame detect changes in resistance as the deck tilts. The PCB interfaces with these gauges via instrumentation amplifiers, converting microstrain variations into voltage outputs that correlate with incline angles.

Optical encoders offer an alternative to Hall sensors for speed measurement, using slotted wheels or reflective markers on the motor shaft. The PCB includes phototransistors or photodiodes to detect light pulses generated by the encoder, with Schmitt trigger circuits on the PCB filtering out signal jitter caused by mechanical vibrations. This ensures stable speed readings even during high-intensity workouts.

2. Signal Processing and Noise Reduction Techniques

Raw sensor data often contains noise from mechanical vibrations, electrical interference, or environmental factors like temperature fluctuations. The PCB must incorporate analog front-end (AFE) circuits to condition signals before digital processing. For example, anti-aliasing filters on the PCB remove high-frequency noise above the Nyquist rate, preventing aliasing artifacts when the microcontroller samples sensor outputs.

Adaptive filtering algorithms implemented in the microcontroller’s firmware further refine sensor data. Moving average filters smooth speed readings to eliminate transient spikes caused by sudden acceleration or deceleration, while Kalman filters fuse data from multiple sensors (e.g., Hall effect and optical encoders) to improve accuracy in dynamic conditions. The PCB should allocate sufficient RAM to store temporary datasets for these algorithms, with flash memory for storing pre-calibrated sensor models that account for motor wear or belt stretching over time.

Thermal compensation is critical for maintaining accuracy in long-duration workouts. The PCB may include thermistors placed near sensors to monitor temperature changes, with the microcontroller adjusting sensor gains or filter coefficients based on thermal drift data. For IMU-based stride analysis, the PCB should support real-time orientation estimation using quaternion algorithms, which reduce computational overhead compared to Euler angles and minimize gimbal lock errors during complex movements.

3. Real-Time Data Processing and User Feedback Systems

The microcontroller on the PCB acts as the central hub for processing sensor data and generating user feedback. It calculates key metrics like distance traveled (by integrating speed over time), calories burned (using metabolic equations based on user weight and speed), and heart rate (if integrated with optical or chest-strap sensors). To ensure responsive performance, the microcontroller should operate at a clock speed sufficient to handle sensor sampling rates of 100–1000 Hz, depending on the complexity of the algorithms.

The PCB must support multiple output interfaces for user feedback. LED displays or LCD drivers connected to the PCB show real-time metrics like speed and incline, with the microcontroller updating display content via SPI or I2C protocols. For treadmills with audio cues, the PCB includes a digital-to-analog converter (DAC) or PWM output to drive speakers, providing verbal prompts for speed adjustments or workout completion.

Wireless connectivity modules, such as Bluetooth Low Energy (BLE) or Wi-Fi, enable data synchronization with fitness apps or cloud platforms. The PCB layout should include antenna matching circuits and RF shielding to optimize signal strength while minimizing interference with other onboard components. Cryptographic accelerators on the PCB encrypt transmitted data, ensuring compliance with privacy regulations like GDPR or HIPAA when sharing workout histories with third-party services.

4. Power Management for Extended Operational Efficiency

Treadmills are often used for continuous workouts lasting 30–60 minutes, demanding efficient power management in the PCB design. Linear regulators with low dropout voltages supply stable power to analog sensors, while switching regulators step down voltages for digital components like the microcontroller and wireless modules. The PCB should include power sequencing circuits to ensure sensors initialize before the microcontroller, preventing data corruption during startup.

Dynamic power scaling is essential for reducing energy consumption. The microcontroller can enter low-power modes during idle periods, with wake-up triggers from button presses or sensor thresholds (e.g., detecting user presence via infrared sensors). For wireless modules, the PCB should support sleep modes that reduce current draw when not transmitting data, with the microcontroller scheduling periodic wake-ups to sync workout metrics.

Battery-backed real-time clocks (RTCs) on the PCB maintain accurate timestamps for workout logs even during power outages. Supercapacitors or rechargeable batteries provide backup power to the RTC, with the PCB including charge management circuits to prevent overcharging or deep discharge. This ensures consistent data logging for users tracking long-term fitness progress.

5. Safety and Compliance Considerations in PCB Design

Treadmills operate under high mechanical stress and electrical loads, requiring PCB assemblies to meet stringent safety standards. Isolation barriers on the PCB separate low-voltage control circuits from high-voltage motor drivers, with creepage and clearance distances exceeding regulatory requirements (e.g., IEC 60335-1 for household appliances). Overcurrent protection circuits, such as fuses or polyfuses, on the PCB prevent damage from motor stalls or short circuits, while thermal fuses cut power if the motor overheats.

Electromagnetic compatibility (EMC) is another critical factor. The PCB layout should minimize loop areas for high-current traces to reduce radiated emissions, with ferrite beads placed on motor power lines to suppress high-frequency noise. Shielding cans or ground planes on the PCB isolate sensitive analog sensors from EMI generated by the motor or wireless modules, ensuring stable operation in noisy environments.

Environmental robustness is ensured through conformal coatings or potting compounds that protect the PCB from moisture and dust, particularly around connectors and exposed traces. For treadmills used in humid climates, the PCB should include hydrophobic coatings on sensor interfaces to prevent condensation-induced shorts. Automated optical inspection (AOI) and X-ray systems during manufacturing verify solder joint quality and component placement accuracy, reducing the risk of field failures due to assembly defects.

6. Future-Proofing with Modular Design and Firmware Updates

To extend the lifespan of treadmill PCB assemblies, manufacturers are adopting modular designs that allow for easy upgrades. For example, sensor modules (e.g., IMUs or strain gauges) can be designed as plug-and-play units with standardized interfaces, enabling users to replace outdated components without replacing the entire PCB. The PCB should include unused GPIO pins or expansion headers to support future sensors, such as ECG modules for heart rate variability analysis or environmental sensors for air quality monitoring.

Firmware updates are essential for adding new features or improving algorithm accuracy over time. The PCB should support bootloader circuits that enable over-the-air (OTA) updates via wireless modules or USB connections. Secure boot mechanisms on the PCB verify firmware integrity before execution, preventing unauthorized modifications that could compromise safety or data privacy.

Machine learning models implemented in the microcontroller can adapt to individual user behaviors, such as optimizing stride analysis for runners with unique gait patterns. The PCB should include sufficient flash memory to store training datasets for these models, with the microcontroller periodically refining algorithms based on new workout data. This ensures the treadmill remains accurate and personalized as the user’s fitness level evolves.

Conclusion

The implementation of motion monitoring circuits in treadmill PCB assemblies requires a multidisciplinary approach that balances sensor accuracy, signal processing efficiency, and user-centric design. By integrating advanced sensors, adaptive algorithms, and robust power management, manufacturers can create systems that deliver precise, reliable feedback while adapting to the evolving needs of fitness enthusiasts. Continuous innovations in sensor miniaturization, low-power electronics, and wireless connectivity will further enhance the capabilities of these essential workout tools.