Exploring PCB assembly manufacturers: Leading industry innovation with excellent quality and efficient service

In today's era of rapid technological development, electronic products have become an indispensable part of people's lives. From smartphones, tablets to smart home devices, from industrial automation control systems to automotive electronic systems, the core of these products cannot be separated from a key component-printed circuit boards (PCBs). As a crucial link in the PCB industry chain, the quality and efficiency of Printed Circuit Board Assembly (PCB assembly) directly determine the performance and reliability of the final electronic products. Among the many PCB assembly manufacturers, there is a world-leading company that has won wide recognition and praise from the market with its excellent quality, efficient production capacity and comprehensive services.

Quality as the foundation, casting industry benchmark

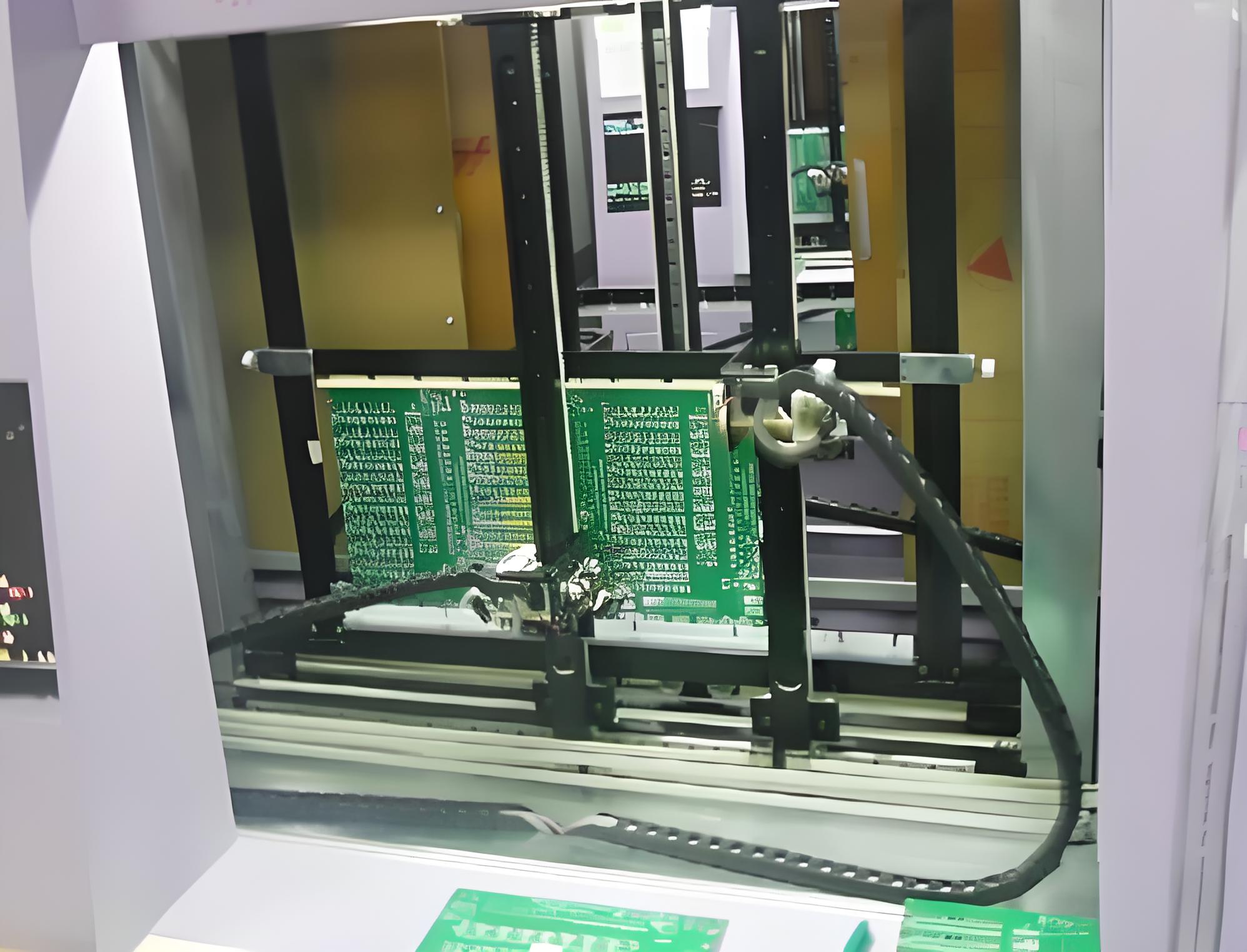

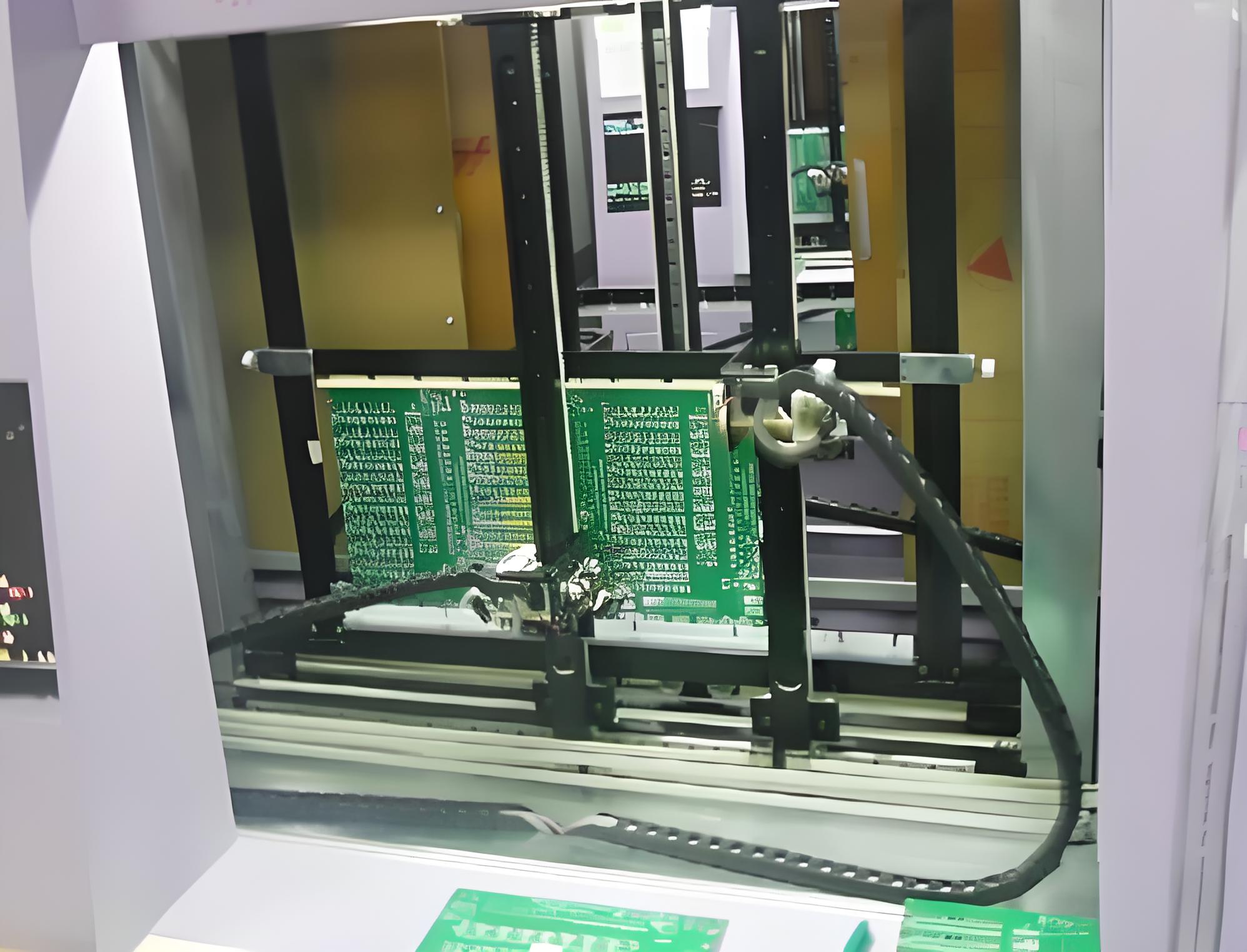

This world-leading PCB assembly manufacturer knows that quality is the foundation of the survival and development of enterprises. From raw material procurement to production and processing, to finished product testing, every link strictly follows the international quality management system standards. The company uses advanced production equipment and technology, equipped with a professional quality inspection team, and conducts strict inspections on each PCB in multiple processes to ensure zero defects in products. Whether it is a high-precision SMT (surface mount technology) patch or a complex DIP (dual in-line package) plug-in, it can be accurate and provide customers with high-quality PCB assembly services.

In terms of raw material selection, the manufacturer has established a long-term and stable cooperative relationship with well-known global suppliers to ensure that the purchased electronic components, PCB boards and other raw materials meet high quality standards. At the same time, the company has also established a complete raw material traceability system. Once a quality problem is found, it can be quickly traced back to the source and take timely measures to ensure product quality.

Efficiency is the wing to help customers seize market opportunities

In the fiercely competitive electronics market, time is money and efficiency is life. This PCB assembly manufacturer knows this well, so it continues to improve production efficiency, optimize production processes, and shorten product delivery cycles. The company has introduced advanced automated production lines and intelligent management systems to realize the automation, informatization and intelligence of the production process. By real-time monitoring of production data, timely adjustment of production plans, and ensuring that orders are delivered on time.

In addition, the manufacturer also has a professional project management team that can provide customers with one-stop services from PCB design, proofing to mass production. Customers only need to provide product requirements and design documents, and manufacturers can respond quickly and provide customers with the most optimized solutions. During the project execution, the project management team will maintain close communication with customers, provide timely feedback on project progress, and ensure that customers are fully aware of the project progress.

Diverse applications, serving multiple industries

PCB, as the core component of electronic products, has a wide range of applications. This world-leading PCB assembly manufacturer, with its rich experience and strong technical strength, provides high-quality PCB assembly services for multiple industries.

Consumer electronics field: With the continuous upgrading of consumer electronic products such as smartphones, tablets, and smart wearable devices, the performance and quality requirements of PCBs are getting higher and higher. The manufacturer can provide customers with high-density and high-reliability PCB assembly solutions to meet the needs of consumer electronic products for thinness, miniaturization, and high performance.

Industrial control field: In industrial automation control systems, the stability and reliability of PCBs are crucial. With its strict quality control system and advanced production technology, the manufacturer provides high-stability PCB assembly services for industrial control equipment to ensure that industrial control systems can operate stably even in harsh environments.

Automotive electronics: With the continuous improvement of the degree of automotive electronics, the performance requirements of automotive electronic systems for PCBs are becoming more and more stringent. The manufacturer is able to provide customers with PCB assembly services that meet the standards of the automotive electronics industry and meet the requirements of automotive electronic systems for harsh environments such as high temperature, high humidity, and high vibration.

Medical electronics: Medical electronic equipment has extremely high requirements for the accuracy and safety of PCBs. The manufacturer uses advanced production processes and strict quality inspection methods to provide high-precision and high-safety PCB assembly services for medical electronic equipment to ensure the accuracy and reliability of medical electronic equipment.

Aerospace: In the aerospace field, the reliability and stability of PCBs are directly related to flight safety. With its outstanding technical strength and strict quality control system, the manufacturer provides high-reliability PCB assembly services for aerospace equipment to meet the requirements of aerospace equipment for extreme environments.

Innovative services, free proofing to help customers develop

In order to better serve customers, the manufacturer has also launched a 2-6 layer PCB free proofing service. Customers only need to provide design files, and the manufacturer can provide customers with high-quality PCB samples in a short time, helping customers to quickly verify design solutions and shorten product development cycles. This service not only reduces customers' R&D costs, but also improves customers' R&D efficiency, winning market opportunities for customers.

In the field of electronic manufacturing services (EMS), this world-leading PCB assembly manufacturer also performs well. As a professional electronic contract manufacturer, the company is able to provide customers with one-stop electronic manufacturing services from PCB design, procurement, production to testing. Customers only need to put forward product requirements, and manufacturers can provide customers with a full range of solutions, allowing customers to focus on product research and development and market expansion.

Conclusion

Today, with the booming global electronics industry, this world-leading PCB assembly manufacturer has become the preferred partner of many customers with its excellent quality, efficient production capacity and comprehensive services. In the future, the manufacturer will continue to uphold the business philosophy of "quality first, customer first", continue to innovate and improve, and contribute more to the development of the global electronics industry.

XDCPCBA PCB assembly factory, as a leader in the industry, has always been committed to providing customers with the best quality PCBA processing plant services and is a PCBA manufacturer you can trust. Whether it is the high-end needs of 2-30 layer PCB manufacturers or the stable supply of PCB suppliers, we can meet them. Choosing XDCPCBA is to choose the dual guarantee of quality and efficiency.