- Home

- Products

- Industrial Control PCB Assembly

- Communication equipment PCB Assembly

- Automotive Electronics PCB Assembly

- Medical Device PCB Assembly

- Security Electronics PCB Assembly

- Consumer Electronics PCB Assembly

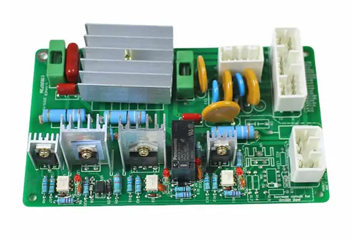

- Power Electrical PCB Assembly

- Double-Sided PCB Manufacturing

- Multilayer PCB Manufacturing

- HDI PCB Manufacturing

- Rigid-Flex PCB Manufacturing

- OEM Product PCBA Solutions

- About Us

- OEM/ODM

- Solutions

- Service

- Blogs

- Contact Us

Please Choose Your Language

- English

- العربية

- Français

- Русский

- Español

- Português

- Deutsch

- italiano

- 日本語

- 한국어

- Nederlands

- Tiếng Việt

- ไทย

- Polski

- Türkçe

- አማርኛ

- ພາສາລາວ

- ភាសាខ្មែរ

- Bahasa Melayu

- ဗမာစာ

- தமிழ்

- Filipino

- Bahasa Indonesia

- magyar

- Română

- Čeština

- Монгол

- қазақ

- Српски

- हिन्दी

- فارسی

- Kiswahili

- Slovenčina

- Slovenščina

- Norsk

- Svenska

- українська

- Ελληνικά

- Suomi

- Հայերեն

- עברית

- Latine

- Dansk

- اردو

- Shqip

- বাংলা

- Hrvatski

- Afrikaans

- Gaeilge

- Eesti keel

- latviešu