Key Technologies in PCB Manufacturing for Energy Storage Systems: Enhancing Efficiency, Safety, and Durability

Energy storage systems (ESS), including battery storage for renewable energy integration and grid stabilization, demand PCBs engineered to handle high currents, thermal stress, and complex electrical architectures. These systems require PCBs that ensure reliable power conversion, precise battery management, and long-term durability under fluctuating environmental conditions. This article explores critical PCB manufacturing technologies for ESS, focusing on high-current handling, thermal management, and advanced material integration to meet the rigorous demands of modern energy storage applications.

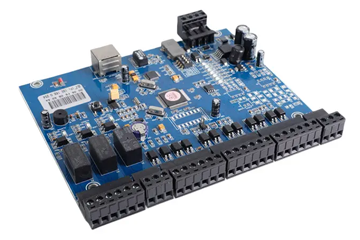

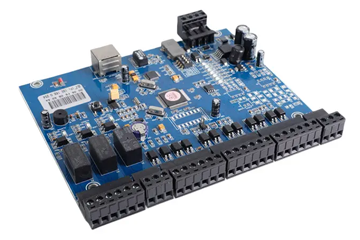

High-Current PCB Design for Power Conversion and Distribution

Energy storage systems rely on bidirectional power conversion—charging during energy surplus and discharging during demand—placing immense strain on PCBs to manage high currents without voltage drops or overheating. To address this, manufacturers employ thick copper PCBs, where copper traces are plated to thicknesses exceeding 3 oz per square foot (oz/ft²) to reduce electrical resistance. Thicker copper layers minimize I²R losses (where I is current and R is resistance), ensuring efficient power transfer between battery modules, inverters, and grid connections.

Another innovation in high-current PCBs is the use of embedded busbars, which integrate conductive bars directly into the PCB substrate to carry currents exceeding 100A. These busbars, often made of aluminum or copper, eliminate the need for external wiring, reducing assembly complexity and improving reliability. Manufacturers optimize busbar placement to balance current distribution across the PCB, preventing localized hotspots that could degrade insulation or solder joints.

High-current PCBs also incorporate wide trace geometries and optimized via designs to enhance current-carrying capacity. For example, via-in-pad technology with copper-filled vias improves thermal and electrical conductivity between layers, enabling compact designs without sacrificing performance. Additionally, manufacturers use partial discharge (PD) testing to verify insulation integrity under high-voltage stress, ensuring long-term reliability in ESS applications where continuous operation is critical.

Thermal Management Solutions for Heat Dissipation in Dense Layouts

Energy storage systems generate significant heat during charging/discharging cycles, particularly in high-power components like power transistors, inductors, and capacitors. Effective thermal management is essential to prevent component degradation, maintain efficiency, and ensure safety. One approach is the use of metal-core PCBs (MCPCBs), which feature a thermally conductive dielectric layer bonded to a metal base (typically aluminum or copper). This structure efficiently transfers heat away from hotspots to external heatsinks or cooling systems, reducing junction temperatures by up to 50% compared to traditional FR-4 PCBs.

Thermal vias are another critical feature in ESS PCBs, facilitating heat transfer from surface-mounted components to inner layers or the PCB’s backside. These vias are often filled with thermally conductive epoxy or solder to enhance conductivity. For high-density designs, manufacturers use staggered via arrays or via-in-pad placements to maximize heat dissipation without increasing PCB thickness. Additionally, embedded thermal planes made of copper or graphite are integrated into the stackup to distribute heat evenly, preventing localized overheating that could lead to thermal runaway in battery cells.

Liquid cooling integration is emerging as a solution for extreme thermal loads in large-scale ESS installations. PCBs for inverters or battery management units (BMUs) may include microchannel coolers or embedded cooling tubes that circulate dielectric fluid to absorb heat directly from components. This approach requires precise alignment between cooling channels and heat-generating areas, often achieved through 3D-printed molds or laser-cut stencils during PCB fabrication. Manufacturers also optimize fluid flow rates and temperatures to balance thermal performance with energy efficiency.

Advanced Material Integration for Environmental and Electrical Robustness

Energy storage systems operate in diverse environments, from indoor data centers to outdoor solar farms, exposing PCBs to temperature extremes, humidity, dust, and chemical contaminants. To ensure long-term reliability, manufacturers adopt advanced materials with enhanced mechanical, thermal, and chemical properties. High-Tg (glass transition temperature) laminates, such as polyimide or BT (Bismaleimide-Triazine) resins, are used to prevent warping or delamination under high temperatures, which can occur during fast charging or high-power discharging cycles. These materials also offer improved resistance to moisture absorption, reducing the risk of electrical leakage or corrosion in humid climates.

For PCBs exposed to mechanical stress, such as those in vibration-prone rack-mounted systems, flexible or rigid-flex architectures are employed. Flexible PCBs made from polyimide films can withstand repeated bending cycles without cracking, while rigid-flex PCBs combine rigid sections for component mounting with flexible sections for interconnections. This hybrid approach reduces the need for connectors or cables, which are potential failure points in dynamic environments. Additionally, manufacturers use adhesiveless flex laminates to achieve thinner profiles and higher reliability in space-constrained applications like battery module interconnects.

Chemical resistance is another priority in ESS PCB materials, particularly for components located near electrolyte storage or cooling systems where leaks may occur. PCBs for these areas are coated with conformal layers made of parylene, silicone, or acrylic resins to protect against chemical attack. These coatings form a thin, impermeable barrier that prevents corrosion without interfering with electrical performance. For high-voltage applications, manufacturers may also apply arc-resistant coatings to inhibit tracking or carbonization on PCB surfaces during electrical faults, enhancing safety in grid-scale storage systems.

As energy storage systems evolve to support higher capacities and faster charging rates, PCB manufacturers must innovate across design, thermal management, and materials to meet these challenges. By integrating high-current solutions, advanced thermal techniques, and durable materials, the industry can produce PCBs that enable safer, more efficient, and longer-lasting energy storage infrastructure.