UWB Smart Factory Solution: How to Optimize Production Safety through Personnel Positioning

In the era of Industry 4.0, smart factories have become the development trend of the manufacturing industry. With the continuous integration of advanced technologies such as the Internet of Things (IoT), big data, and artificial intelligence (AI), factories are becoming more intelligent, efficient, and safe. Among them, Ultra Wide Band (UWB) positioning technology, as a key technology for realizing indoor high-precision positioning, is playing an increasingly important role in smart factories. This article will explore how to optimize production safety in smart factories through UWB personnel positioning, and naturally introduce XDCPCBA, an electronic service manufacturer that provides OEM services, including relevant keywords such as pcb manufacturing companies, pcb board builder, etc.

I. Overview of UWB Positioning Technology

(I) Technical Principles

UWB positioning technology is based on ultra-wideband signals for localization. Ultra-wideband signals have an extremely wide bandwidth and very low power spectral density, enabling high-precision positioning in complex environments. Compared with traditional positioning technologies such as Wi-Fi and Bluetooth, UWB positioning technology offers higher positioning accuracy, stronger anti-interference capabilities, and lower power consumption.

(II) Key Components

UWB Tags: These are worn by personnel or attached to objects that need to be located. They continuously emit ultra-wideband signals, which are the basis for the positioning system to determine the position of the target.

UWB Base Stations: Distributed at various key locations within the factory, they receive the signals emitted by UWB tags and transmit them to the positioning server. The number and layout of UWB base stations directly affect the positioning range and accuracy of the system.

Positioning Server: It calculates the position information of the UWB tags through specific algorithms, such as Time of Arrival (TOA), Time Difference of Arrival (TDOA), and Angle of Arrival (AOA). The positioning server can also integrate with other factory management systems to realize more intelligent functions.

(III) Performance Indicators

UWB Positioning Accuracy: UWB positioning technology can typically achieve centimeter-level positioning accuracy, which is crucial for the precise management of personnel and equipment in smart factories. For example, in a workshop with complex equipment layout, accurate personnel positioning can help avoid collisions between personnel and equipment, ensuring production safety.

UWB Positioning Range: The coverage range of a UWB positioning system can be adjusted according to actual needs. By reasonably arranging UWB base stations, comprehensive coverage of an entire factory building or even multiple buildings can be achieved. Some professional UWB positioning systems support UWB 3D positioning, enabling accurate determination of the target's position in three-dimensional space, which is particularly useful in multi-story factories.

UWB Positioning Cost: With the continuous development of technology and large-scale production, the cost of UWB positioning systems has gradually decreased. However, for some small and medium-sized factories, cost is still a factor that needs to be considered. By optimizing system design and selecting appropriate hardware devices, the cost can be effectively controlled while ensuring positioning performance.

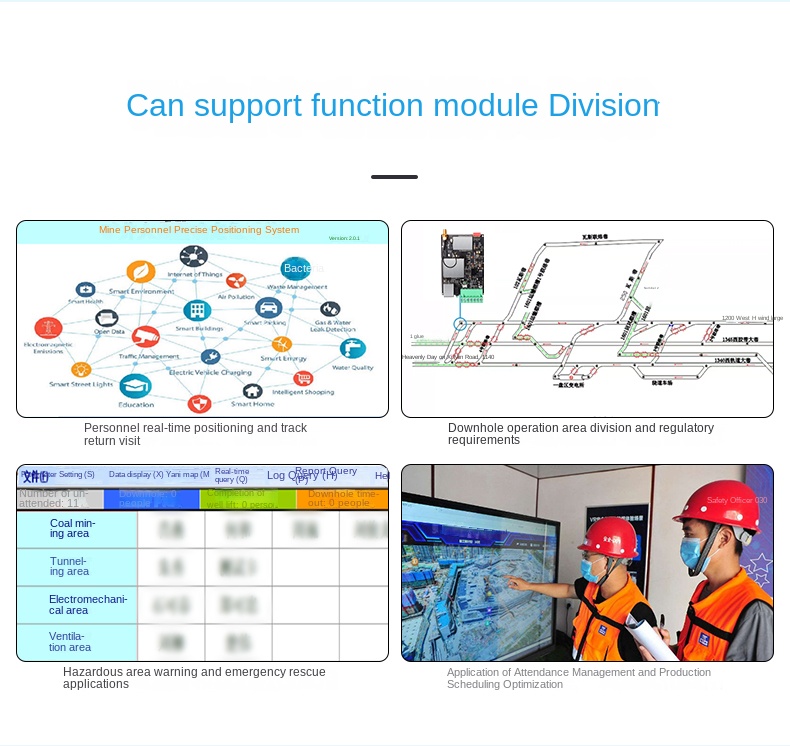

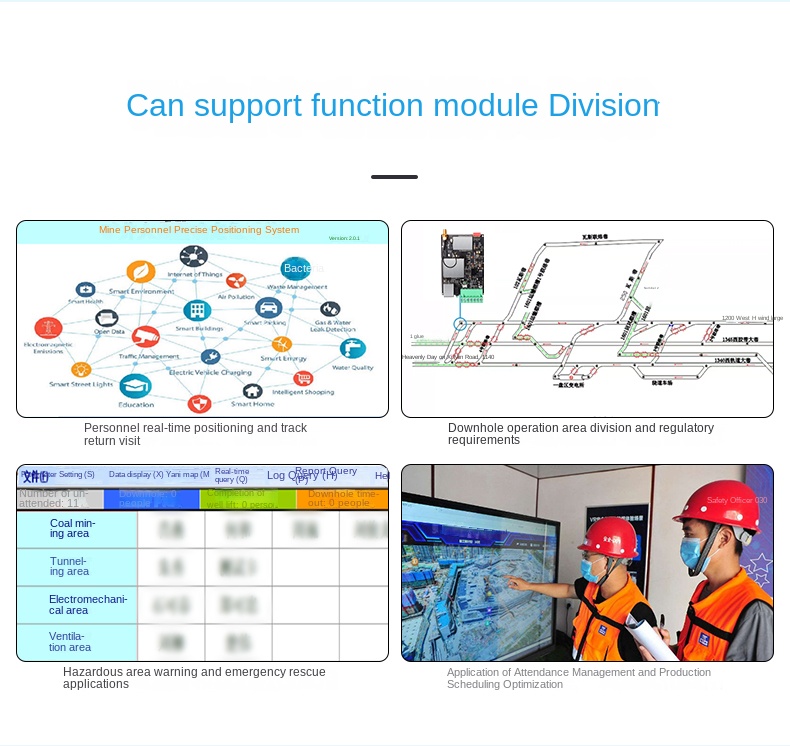

II. Applications of UWB Personnel Positioning in Smart Factories

(I) Safety Monitoring

Access Control: By setting up virtual electronic fences in the factory, UWB personnel positioning systems can monitor whether personnel enter or leave restricted areas in real-time. When personnel enter unauthorized areas, the system can immediately issue an alarm to notify security personnel to take timely measures, preventing potential safety accidents.

Collision Avoidance: In workshops with a large number of moving equipment, such as forklifts and automated guided vehicles (AGVs), UWB personnel positioning can accurately locate the positions of personnel and equipment. When the distance between personnel and equipment is too close, the system can issue a warning to remind both parties to take evasive actions, reducing the risk of collisions.

Emergency Rescue: In the event of an emergency, such as a fire or earthquake, the UWB personnel positioning system can quickly locate the positions of all personnel in the factory. This helps rescue teams formulate reasonable rescue plans, improve rescue efficiency, and reduce casualties.

(II) Production Management

Work Efficiency Analysis: By tracking the movement trajectories and working hours of personnel, the UWB personnel positioning system can analyze the work efficiency of each employee. Managers can identify bottlenecks in the production process and take targeted measures to improve production efficiency.

Task Allocation: According to the real-time location information of personnel, the system can dynamically allocate tasks. For example, when a new order arrives, the system can quickly find the nearest available personnel to handle it, reducing task waiting time and improving production flexibility.

Training Management: For new employees, the UWB personnel positioning system can record their movement paths and working processes during training. Managers can analyze these data to evaluate the training effect and provide targeted guidance to help new employees quickly master work skills.

(III) Asset Management

Equipment Tracking: By installing UWB tags on expensive equipment, the factory can keep real-time track of the equipment's location and usage status. This helps prevent equipment theft and misplacement, and improves equipment utilization efficiency.

Inventory Management: For raw materials and finished products, UWB positioning technology can realize precise inventory management. By installing UWB tags on the packaging of goods, the factory can monitor inventory levels, locations, and movement in real-time, reducing inventory costs and improving logistics efficiency.

III. XDCPCBA's Role in UWB Positioning Device Manufacturing

As a professional electronic service manufacturer, XDCPCBA plays an important role in the circuit board manufacturing of UWB positioning devices. XDCPCBA, as a pcb manufacturing companies, has rich experience and advanced technology in circuit board manufacturing, providing a solid foundation for the development and application of UWB positioning technology.

(I) High-quality Circuit Board Manufacturing

XDCPCBA, as a pcb board builder and pcb company, has a comprehensive pcb design and fabrication process. From the selection of raw materials to the control of production processes, every link is strictly supervised to ensure the performance and stability of circuit boards. In the manufacturing of UWB positioning device circuit boards, XDCPCBA adopts high-quality materials and advanced production technology to meet the high-precision and high-reliability requirements of UWB positioning systems.

(II) Customized Services

Different smart factories may have different requirements for UWB positioning devices. XDCPCBA, as a professional pcb board manufacturer and pcb board company, offers custom pcb boards and custom pcb design service. Whether it is for the miniaturization and low-power design of UWB tags or the high-performance and high-reliability requirements of UWB base stations, XDCPCBA can provide customized design and manufacturing according to the specific needs of customers to meet the special requirements of different smart factories.

(III) Cost Control

In the manufacturing industry, cost control is an important consideration. XDCPCBA optimizes the pcb manufacturing assembly process, improves production efficiency, and maintains good cooperation with suppliers, effectively reducing pcb board cost and pcb manufacturing price. This provides UWB positioning device manufacturers with a competitive cost advantage, enabling wider application of UWB positioning technology in smart factories.

(IV) PCB Manufacturing Services

XDCPCBA, as a pcb factory and pcb board maker, provides a full range of pcb manufacturing services, including pcb design and fabrication, circuit manufacturing, pcb layout services, and pcb fabrication service. Whether it is a small-batch prototype production or a large-scale mass production, XDCPCBA can meet the needs of customers with high-quality and efficient services.

IV. Challenges and Solutions for UWB Personnel Positioning in Smart Factories

(I) Signal Interference Issues

There are a large number of electronic devices in smart factories, such as production equipment, communication equipment, and automated systems, which may interfere with UWB signals and affect positioning accuracy. Solutions include optimizing the layout of UWB base stations, selecting appropriate signal frequencies and modulation methods, and adopting anti-interference algorithms. Meanwhile, XDCPCBA can adopt shielding, filtering, and other technical means in circuit board design and manufacturing to improve the anti-interference ability of circuit boards and ensure the stable operation of UWB positioning devices.

(II) System Integration Issues

UWB personnel positioning systems need to be integrated with other factory management systems, such as production management systems, security monitoring systems, and equipment maintenance systems. To solve the integration problem, the UWB positioning system needs to have good openness and compatibility, enabling seamless integration with other factory systems. Meanwhile, XDCPCBA can follow relevant industry standards and specifications in circuit board design and manufacturing to ensure that UWB positioning devices are compatible with various factory systems.

(III) Privacy Protection Issues

Personnel positioning involves employees' private information. How to protect employee privacy is an important issue. Factories need to formulate strict privacy protection policies, encrypt the data of the UWB positioning system, and restrict data access permissions. Meanwhile, developers of the UWB positioning system also need to strengthen technological research and development, adopting anonymization processing and other technical means to ensure that employee privacy is not leaked.

V. Future Development Trends of UWB Personnel Positioning in Smart Factories

(I) Integration with Other Technologies

In the future, UWB personnel positioning technology will be deeply integrated with technologies such as IoT, big data, and AI. Through IoT technology, UWB positioning devices can interconnect with other smart devices in the factory, achieving more intelligent production management. Big data and AI technologies can analyze and mine the data collected by the UWB positioning system to support factory decision-making, such as optimizing production scheduling, predicting equipment failures, and improving personnel efficiency.

(II) Expansion of Application Scenarios

In addition to the current applications of personnel positioning, UWB technology will be applied in more aspects of smart factories. For example, in material handling, it can be used for precise tracking of materials and products, improving logistics efficiency; in quality control, it can monitor the operation process of workers to ensure that production operations comply with standards.

(III) Cost Reduction and Increased Popularity

With the continuous progress of technology and large-scale production, the cost of UWB positioning systems will further decrease. At the same time, governments and enterprises will increase their support for the application of UWB technology in smart factories, promoting its wider adoption in more factories. This will help improve production safety, efficiency, and quality, bringing greater economic and social benefits.

VII. Conclusion

UWB personnel positioning technology is an important means to optimize production safety in smart factories. By accurately locating personnel, it can realize real-time monitoring, collision avoidance, and emergency rescue, effectively reducing safety accidents. XDCPCBA, as a professional electronic service manufacturer, plays an important role in the circuit board manufacturing of UWB positioning devices. By providing high-quality, customized, and cost-effective circuit board solutions, it has promoted the application of UWB technology in smart factories. Although UWB personnel positioning technology still faces some challenges in smart factories, with the continuous development and improvement of technology, it is believed that it will play a more important role in the future manufacturing industry, making greater contributions to the intelligent transformation and high-quality development of factories.