Elevator controller PCBA assembly and processing: the secret to reducing costs and improving efficiency

In the elevator control system, printed circuit board assembly (PCBA) is one of the core components, and its quality and efficiency are directly related to the overall performance and operational reliability of the elevator. In order to stand out in the highly competitive market, elevator manufacturers are constantly seeking ways to reduce costs and improve production efficiency. As a leading provider in the printed circuit board (PCB) industry, XDCPCBA provides comprehensive capabilities from PCB manufacturing to PCBA assembly services, and is an ideal partner for elevator controller PCBA assembly and processing. This article will explore how to achieve cost reduction and efficiency improvement in elevator controller PCBA assembly and processing through XDCPCBA's professional services.

1. XDCPCBA's professional background and strength

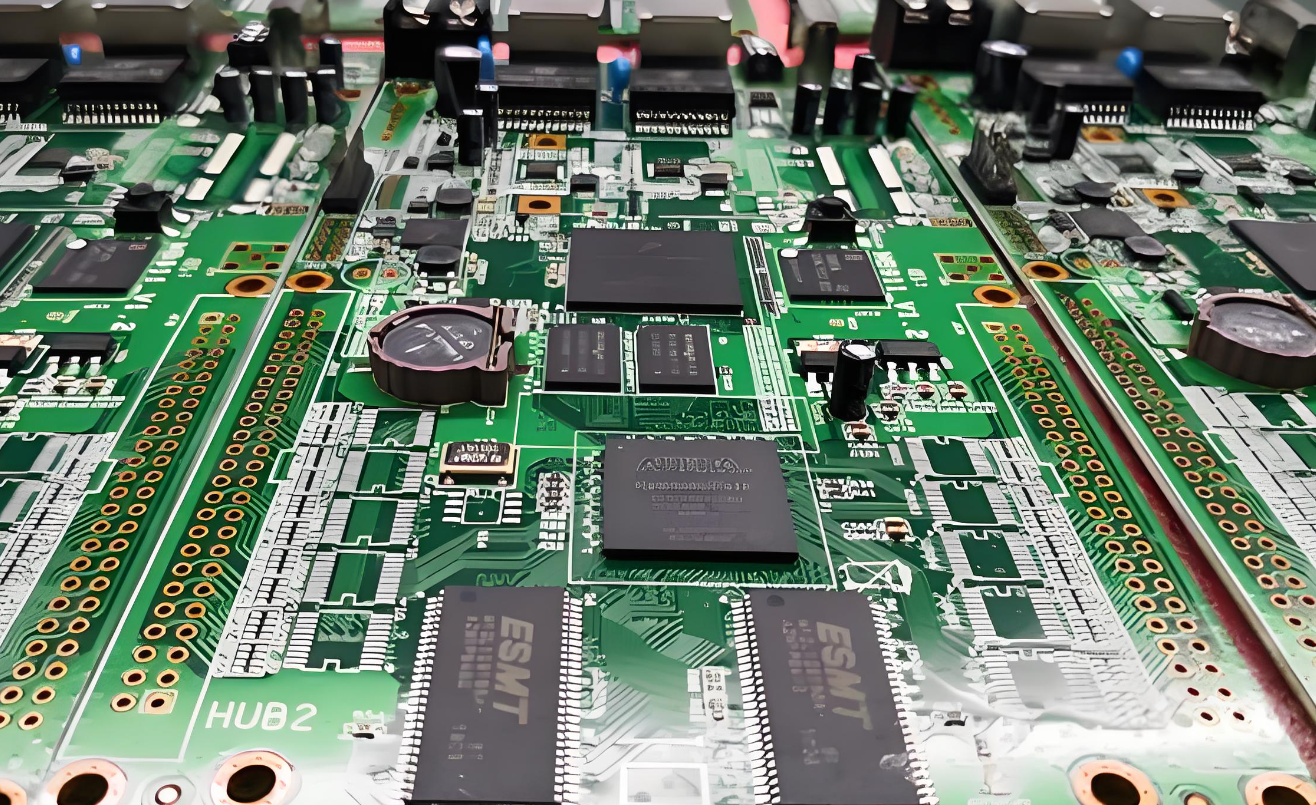

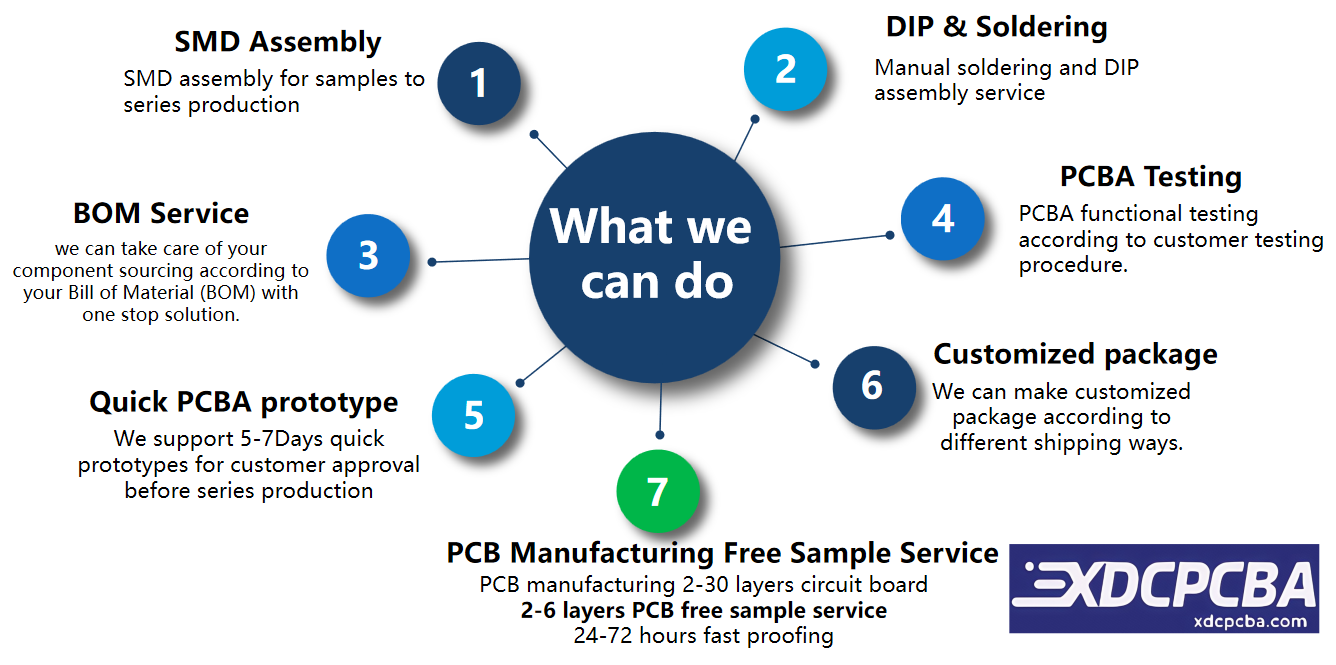

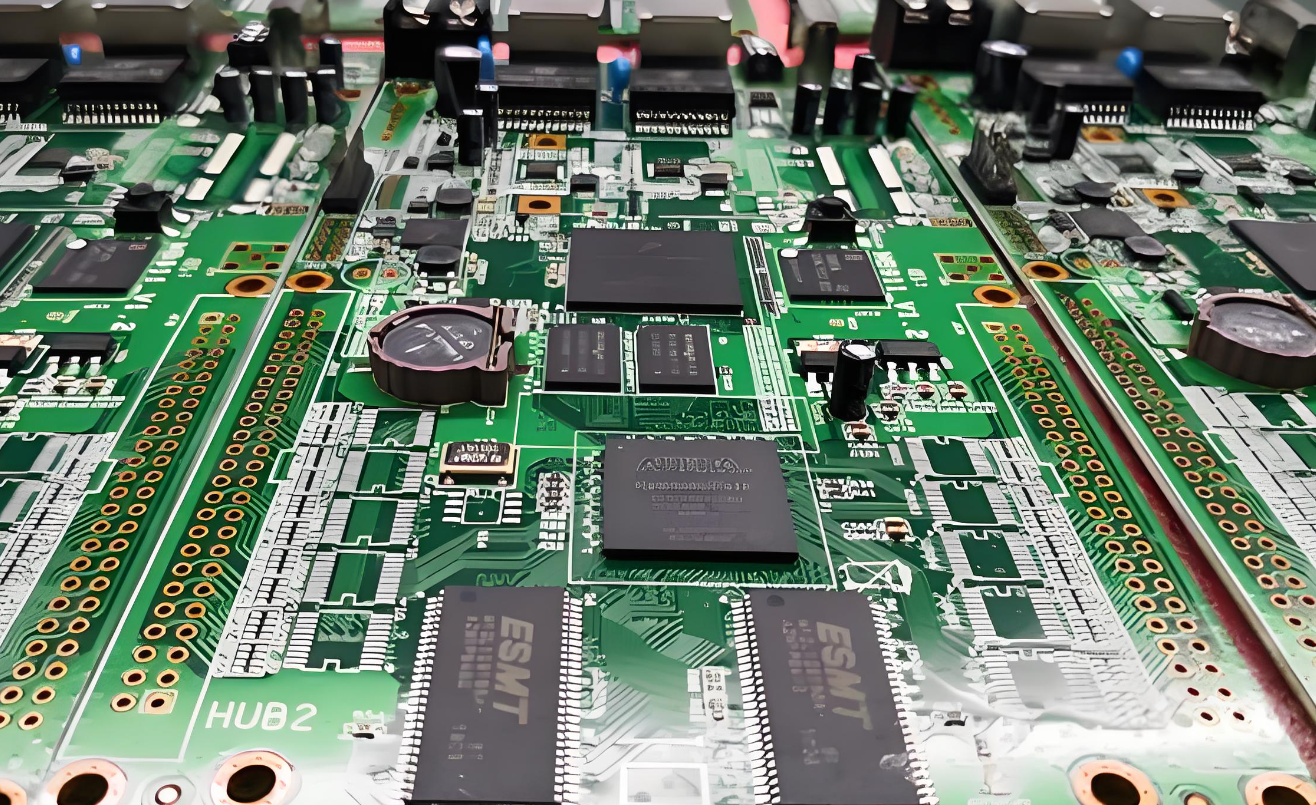

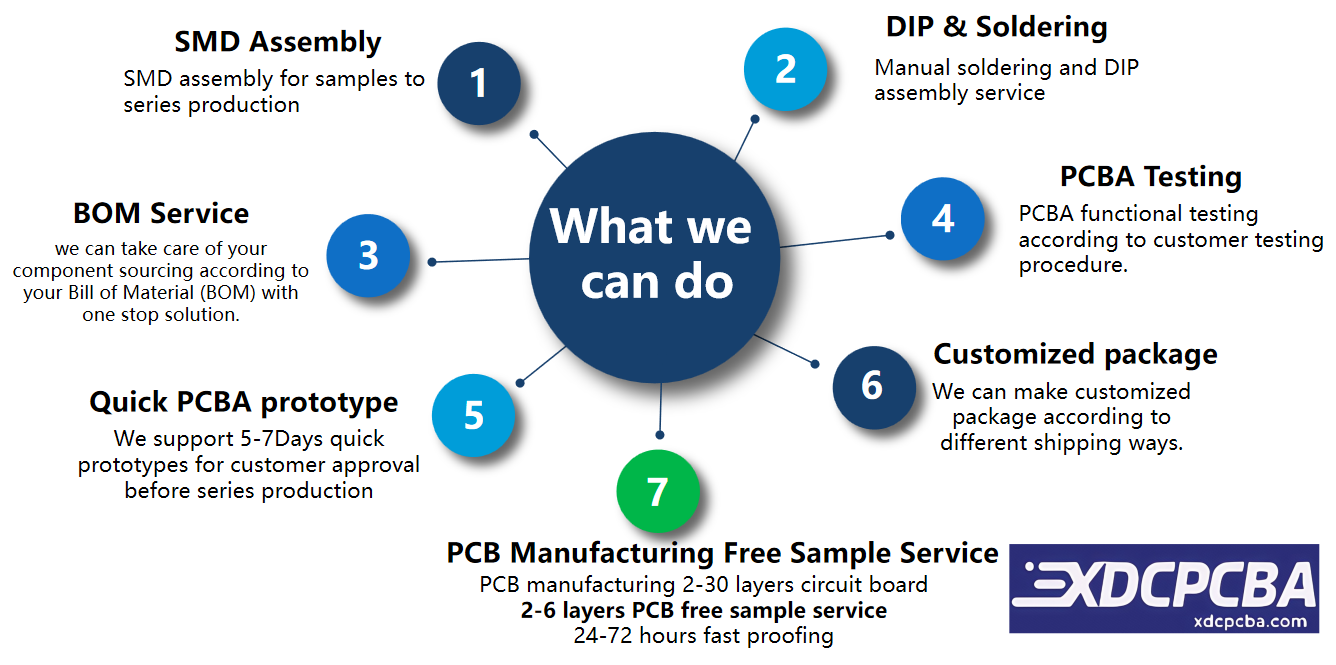

XDCPCBA not only has its own PCB factory, but also focuses on producing high-quality PCBs from 2 to 30 layers, demonstrating strong production strength and a deep understanding of different customer needs. The company uses advanced PCB manufacturing technology and assembly processes to ensure that each circuit board can achieve high precision and high reliability. XDCPCBA's professional field covers many types of PCBs, such as double-sided PCB, multi-layer PCB, high-frequency PCB, HDI PCB, rigid-flex PCB, aluminum-based PCB, prototype PCB, flexible PCB, ceramic PCB, large-size PCB and copper-based PCB, etc.

In order to further reflect the focus on customer needs, XDCPCBA launched a free sample service for 2 to 6-layer PCBs, which not only demonstrates the company's commitment to customer satisfaction, but also provides customers with low-cost testing and development opportunities. Through this service, elevator manufacturers can verify and optimize the design and function of the circuit board without adding additional costs.

2. Comprehensive PCBA assembly service

As a professional PCB supplier, XDCPCBA also excels in PCBA manufacturing. Its PCB assembly factory provides a wide range of PCBA processing services, covering multiple industries such as industrial automation, automotive electronics, communication equipment, Internet of Things, mechanical equipment, instrumentation, power equipment, medical equipment, aerospace, power electrical, home appliances and consumer electronics. This cross-industry service capability enables XDCPCBA to flexibly respond to the assembly needs of different elevator controller PCBAs and provide customized solutions.

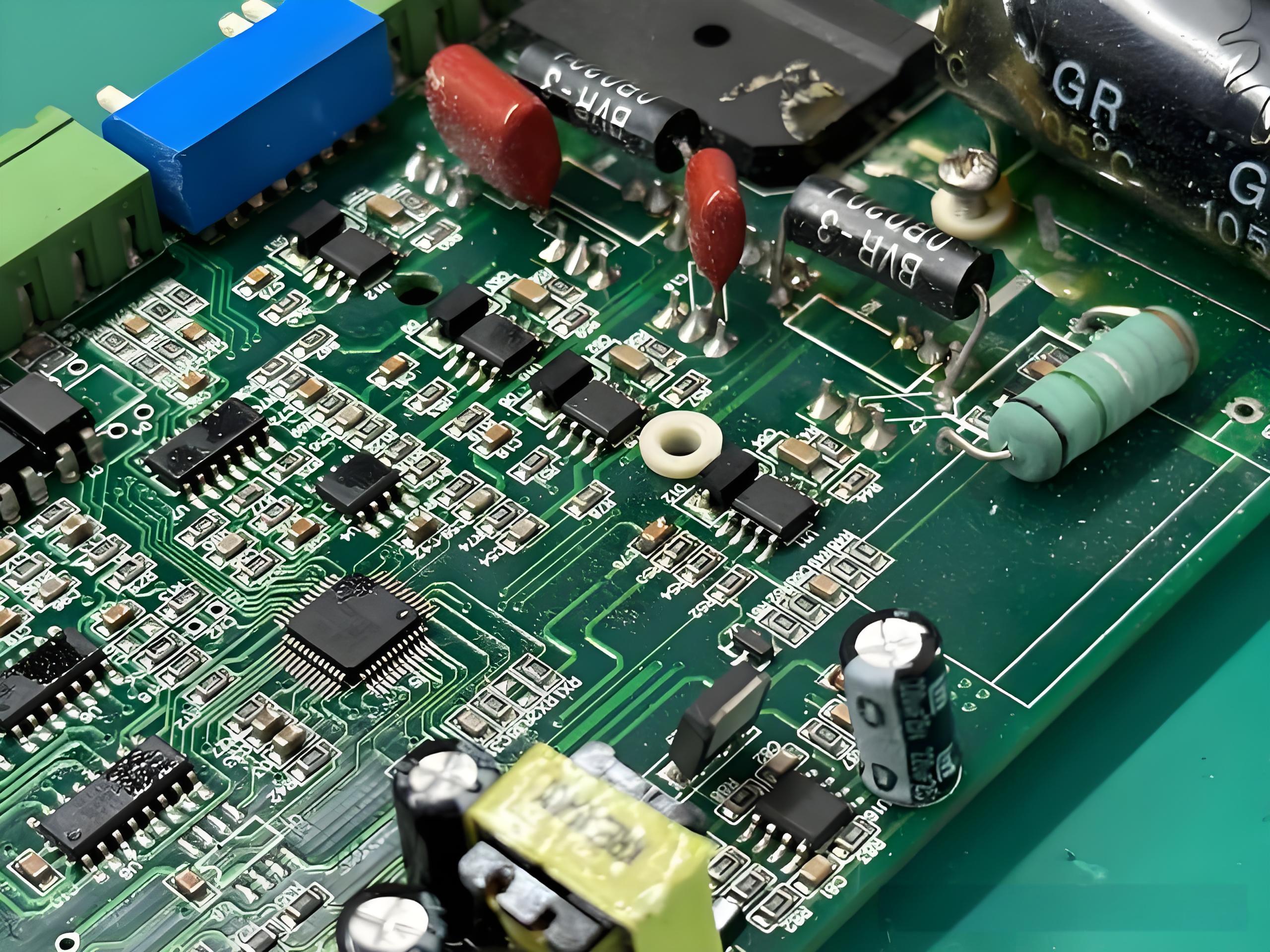

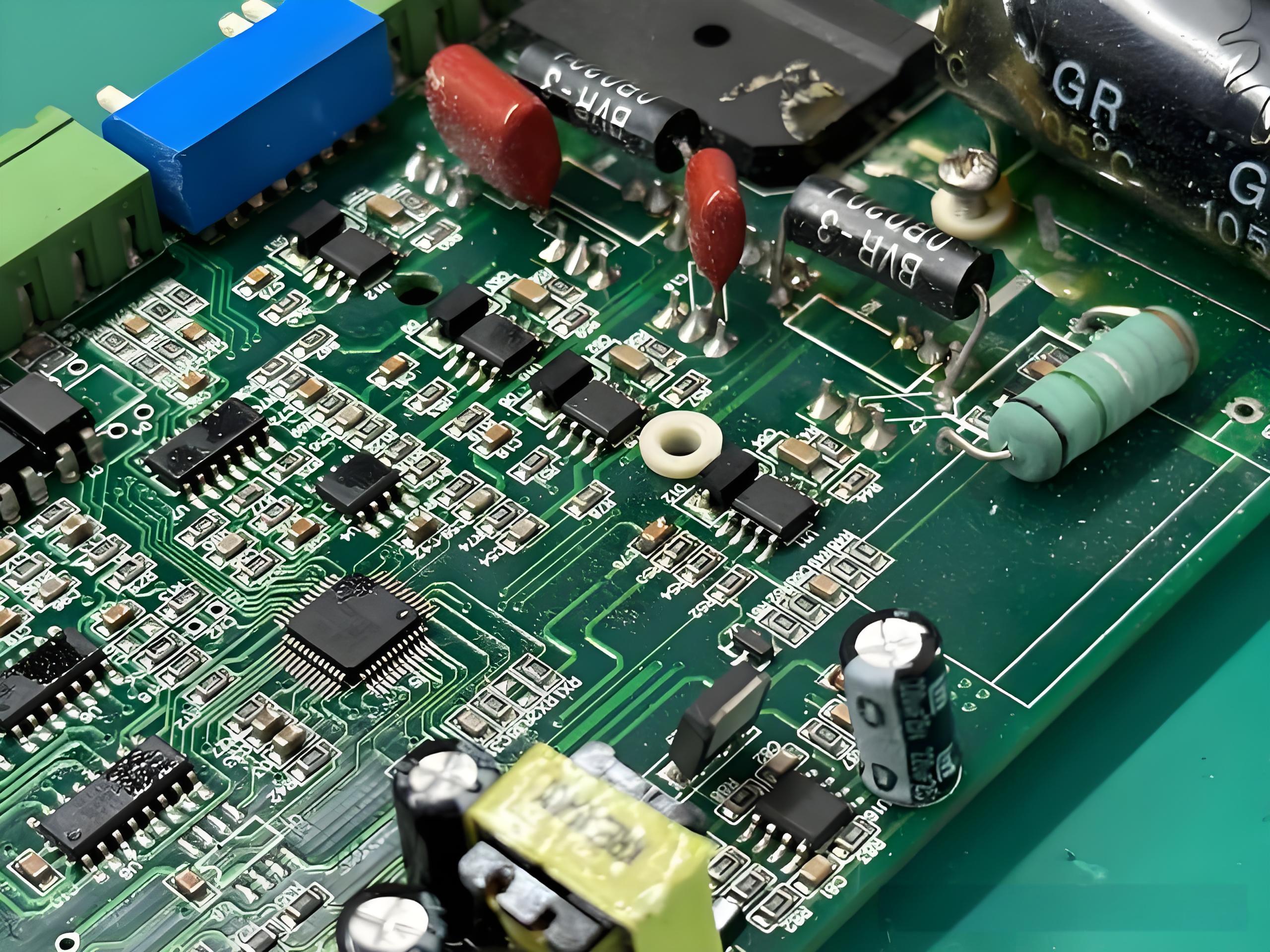

During the PCBA assembly process, XDCPCBA uses advanced SMT (surface mount technology), SMD (surface mount device) and electronic assembly technology to ensure that each component can be accurately and reliably fixed on the circuit board. At the same time, the company has also established a strict testing and quality control system to conduct comprehensive functional and reliability tests on the assembled circuit boards to ensure that each circuit board can meet customer expectations and requirements.

3. Effective strategies to reduce costs

Optimize design and material selection

During the design stage of the elevator controller PCBA, XDCPCBA provides comprehensive PCB design services, including PCB layout design, PCB etching and circuit board design. By optimizing the circuit board layout and wiring, unnecessary material and process costs can be reduced. At the same time, XDCPCBA also provides a variety of circuit board material options, and recommends the most suitable materials to customers according to the specific application scenarios and needs of the elevator controller, thereby reducing costs while ensuring performance.

Bulk procurement and production efficiency improvement

As a professional PCB and PCBA manufacturer, XDCPCBA has strong supply chain management capabilities. By establishing long-term cooperative relationships with suppliers, the company is able to purchase raw materials and components at more competitive prices. In addition, XDCPCBA further reduces production costs by optimizing production processes and improving production efficiency. For example, adopting automated production equipment, improving the utilization rate of production lines and reducing waste in the production process.

Flexible production mode and rapid response

The market demand for elevator controllers is often diverse and uncertain. XDCPCBA provides a flexible production mode that can quickly adjust production plans according to customer order volume and delivery time requirements. This flexibility not only helps to reduce inventory backlogs and capital occupation, but also ensures that customers can get the required products in time when they need them.

IV. Key measures to improve efficiency

Advanced production technology and equipment

XDCPCBA continues to introduce advanced production technology and equipment to improve the production efficiency and quality of PCBA assembly. For example, the use of high-speed placement machines, automatic optical inspection equipment (AOI) and online testing equipment (ICT) can greatly improve assembly speed and detection accuracy, and reduce human errors and rework rates.

Standardization and process optimization

By establishing standardized production processes and operating specifications, XDCPCBA can ensure that each step of the production process can be carried out in accordance with established standards. This not only helps to improve production efficiency, but also ensures the consistency and stability of product quality. At the same time, the company also regularly optimizes and improves the production process to eliminate bottlenecks and waste and further improve overall production efficiency.

Intelligent management and data analysis

XDCPCBA uses intelligent management systems to monitor and manage the production process in real time. By collecting and analyzing production data, the company can promptly discover and solve problems in production and adjust production plans to cope with market changes. In addition, intelligent management can also help companies better predict and plan future production needs, thereby improving the responsiveness and flexibility of the supply chain.

V. As an ideal partner for elevator controller PCBA

XDCPCBA has become an ideal partner for elevator controller PCBA assembly and processing with its strong PCB manufacturing and PCBA assembly capabilities, comprehensive service range, and effective strategies to reduce costs and improve efficiency. By working with XDCPCBA, elevator manufacturers can not only obtain high-quality circuit board components, but also achieve significant results in reducing costs and improving production efficiency.

In short, as a leader in the PCB and PCBA industry, XDCPCBA provides strong support for elevator controller PCBA assembly and processing with its professional technical strength, comprehensive service range and flexible production model. Through measures such as optimizing design and material selection, bulk procurement and production efficiency improvement, and advanced production technology and equipment, XDCPCBA has helped elevator manufacturers achieve the goal of reducing costs and improving efficiency. In the future, with the continuous advancement of technology and the continuous changes in the market, XDCPCBA will continue to be committed to innovation and improvement to provide elevator manufacturers with better quality and more efficient services.