From PCB to PCBA: In-depth analysis of quality control in the manufacturing process of elevator controllers

In today's highly intelligent building environment, elevator controllers are key devices that connect people and buildings, and their stability and reliability are crucial. From the initial PCB (printed circuit board) design and manufacturing to the final PCBA (printed circuit board assembly) completion, every step contains the ultimate pursuit of quality. XDCPCBA, as a leader in the PCB industry, not only provides a full-chain service from PCB manufacturing to PCB assembly, but also ensures the excellent quality of products with its deep expertise and exquisite craftsmanship in the manufacturing process of elevator controllers.

1. PCB manufacturing: the source of quality

XDCPCBA, as a leader in the printed circuit board industry, has its own independent PCB factory, focusing on the production of high-quality PCBs from 2 to 30 layers. This not only demonstrates its strong production capacity, but also reflects a deep understanding of the diverse needs of customers. In the PCB manufacturing process of elevator controllers, XDCPCBA strictly follows the ISO9001 quality management system standards, from raw material procurement, production process control to finished product inspection, every link strives for perfection.

Raw material selection:

High-quality raw materials are the basis for manufacturing high-quality PCBs. XDCPCBA has established long-term cooperative relationships with the world's leading suppliers of raw materials such as copper foil and resin to ensure that all materials meet international environmental standards and meet the requirements of elevator controllers for special environments such as high temperature, high humidity, and high voltage.

Advanced production process:

XDCPCBA uses advanced technologies such as laser direct imaging (LDI) and electrochemical deposition (ECD) to achieve high-precision circuit production and multi-layer board lamination. At the same time, through strict etching and electroplating process control, the conductivity and mechanical strength of the circuit board are ensured.

Strict quality control:

During the manufacturing process, XDCPCBA implements comprehensive quality control measures. From raw material warehousing inspection to finished product factory testing, each process is strictly controlled. Especially for elevator controllers, XDCPCBA has also added additional reliability tests such as thermal stress testing, humidity cycle testing, etc. to ensure the stable operation of the circuit board under various extreme conditions.

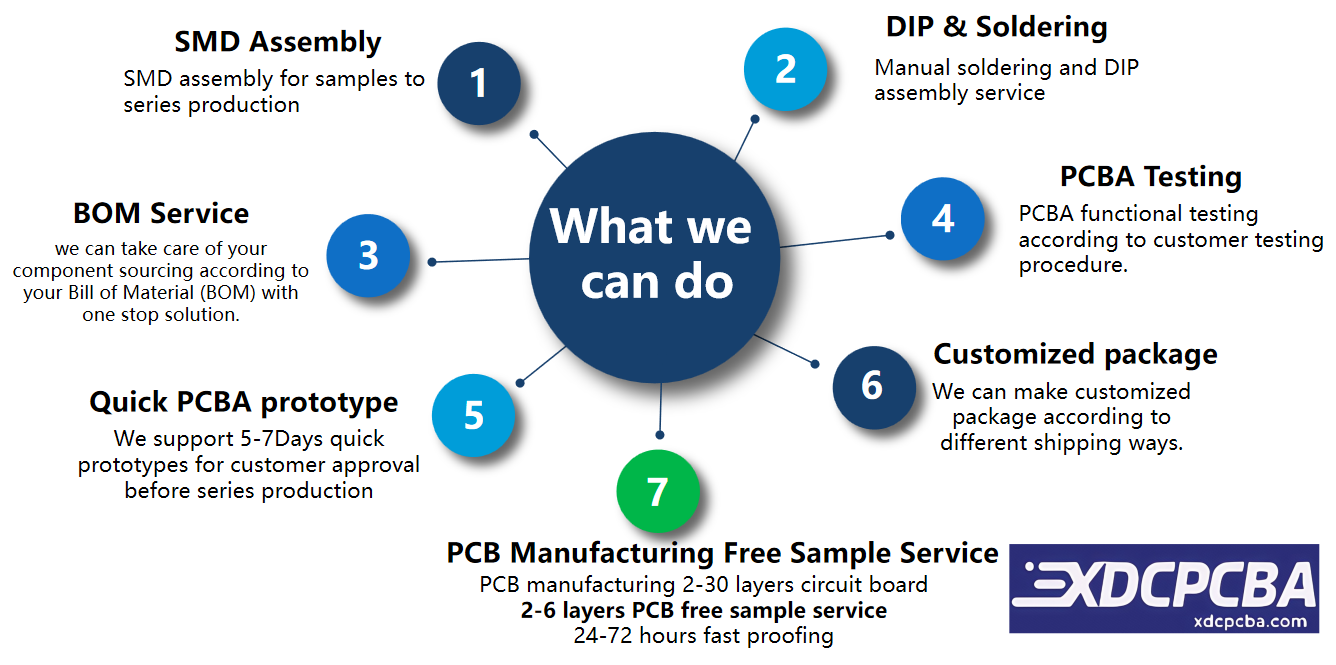

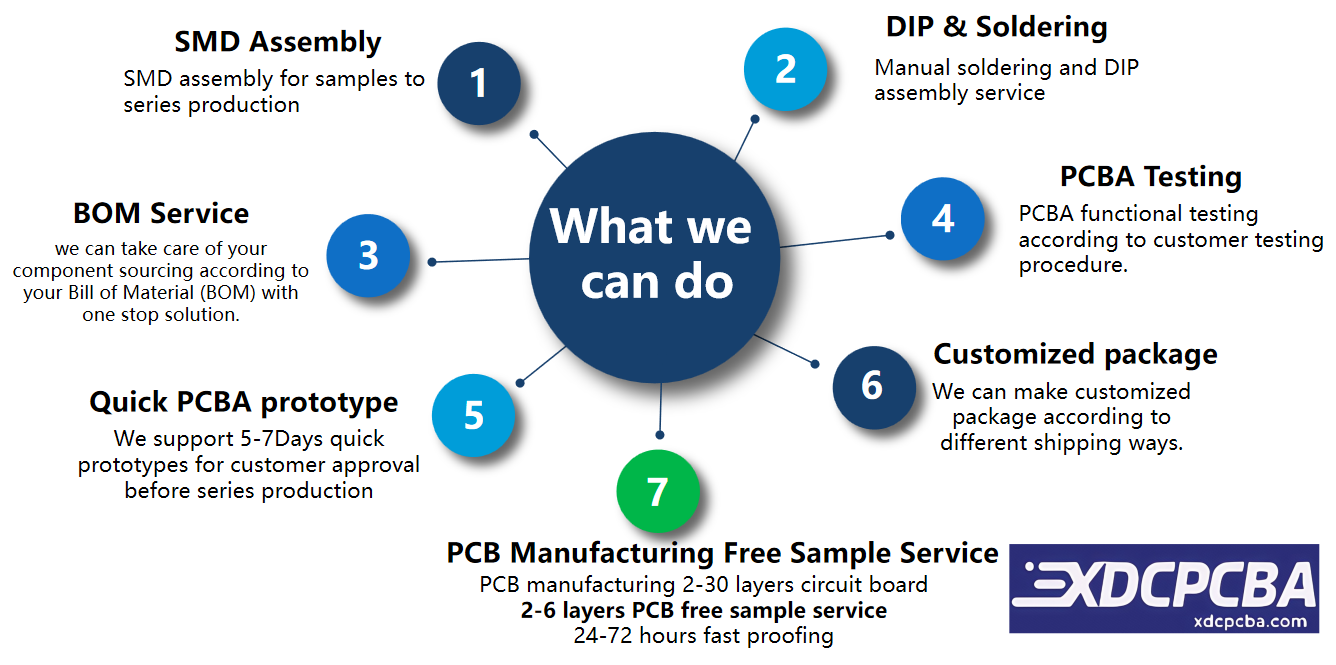

2. Free sample service: the embodiment of customer satisfaction

In order to further meet the diverse needs of customers, XDCPCBA has specially launched a free sample service for 2 to 6 layers of PCB. This move not only demonstrates XDCPCBA's high attention to customer satisfaction, but also reflects its strong strength and confidence in the field of PCB manufacturing. Through the free sample service, customers can experience XDCPCBA's high-quality products and professional services without incurring any cost, so as to trust and choose XDCPCBA as a long-term partner.

III. PCBA assembly: quality upgrade

As a professional PCBA manufacturer, XDCPCBA also excels in PCB assembly. Its PCB assembly factory is equipped with advanced SMT (surface mount technology) and THT (through-hole mounting technology) production lines, which can efficiently and accurately complete the mounting and welding of various electronic components.

Component procurement and inspection:

XDCPCBA has established long-term cooperative relations with world-renowned electronic component suppliers to ensure that all components are from formal channels and of reliable quality. Before the components are put into storage, XDCPCBA will also conduct strict quality inspections, including appearance inspections, performance tests, etc., to ensure that every component meets the design requirements.

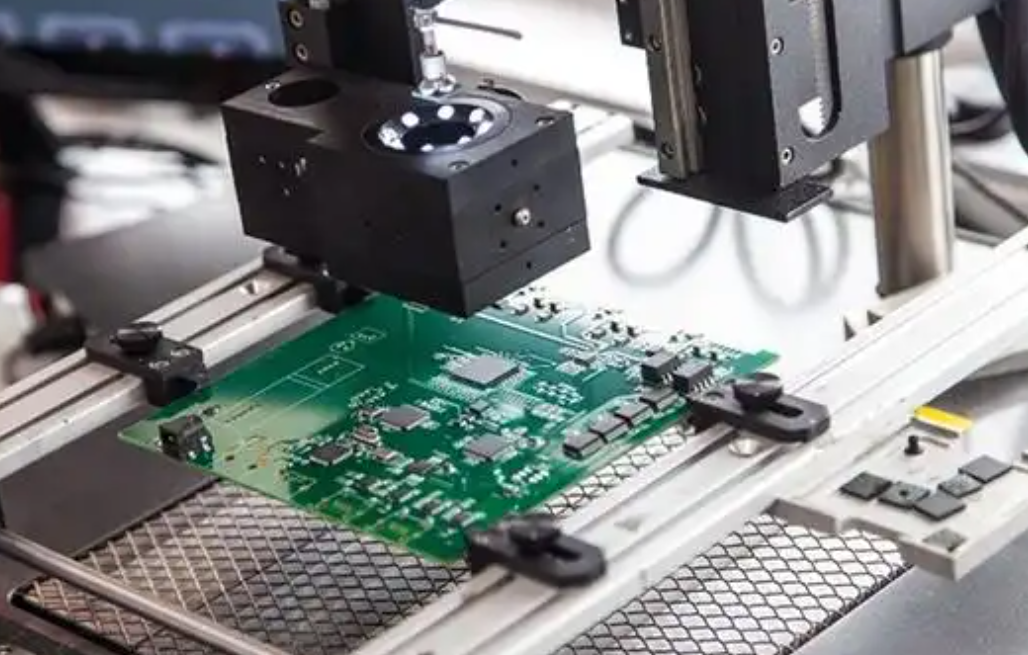

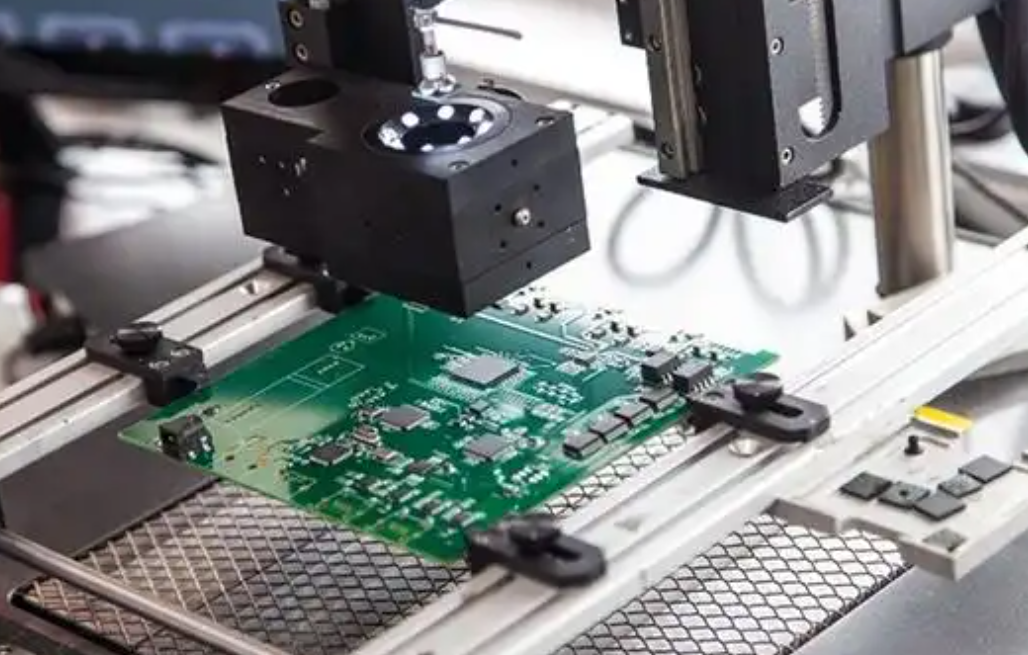

High-precision mounting and welding:

With advanced SMT mounting equipment and precise welding technology, XDCPCBA can achieve high-precision mounting and stable welding of components. Especially for the tiny components and complex circuit structures in the elevator controller, XDCPCBA uses advanced machine vision technology and automatic calibration system to ensure the accuracy and consistency of mounting and welding.

Comprehensive testing and quality control:

After the PCBA assembly is completed, XDCPCBA will conduct comprehensive functional and performance tests. This includes ICT (in-circuit tester) testing, FCT (functional tester) testing, and aging testing to ensure that the elevator controller can operate stably under various working conditions. At the same time, XDCPCBA has also established a complete quality traceability system, and each PCBA product is uniquely identified and recorded in detail so that problems can be quickly located and solved when they occur.

4. Diversified PCB types and advanced technology applications

XDCPCBA's professional fields are not limited to traditional double-layer PCBs and multi-layer PCBs, but also include high-frequency PCBs, HDI PCBs, rigid-flex PCBs, aluminum-based PCBs, prototype PCBs, flexible PCBs, ceramic PCBs, large-size PCBs, and copper-based PCBs. These different types of PCBs play their own unique roles in elevator controllers. For example, high-frequency PCBs are suitable for high-speed signal transmission; HDI PCBs can meet the needs of elevator controllers for miniaturization and high density; and rigid-flex PCBs can achieve more flexible spatial layout while ensuring circuit stability.

In terms of technical application, XDCPCBA has always been at the forefront of the industry. The company uses advanced laser drilling technology, blind and buried hole technology, lead-free soldering technology, etc. to ensure the high precision, high reliability and environmental protection of elevator controllers during the manufacturing process.

V. PCB design service: quality assurance from the source

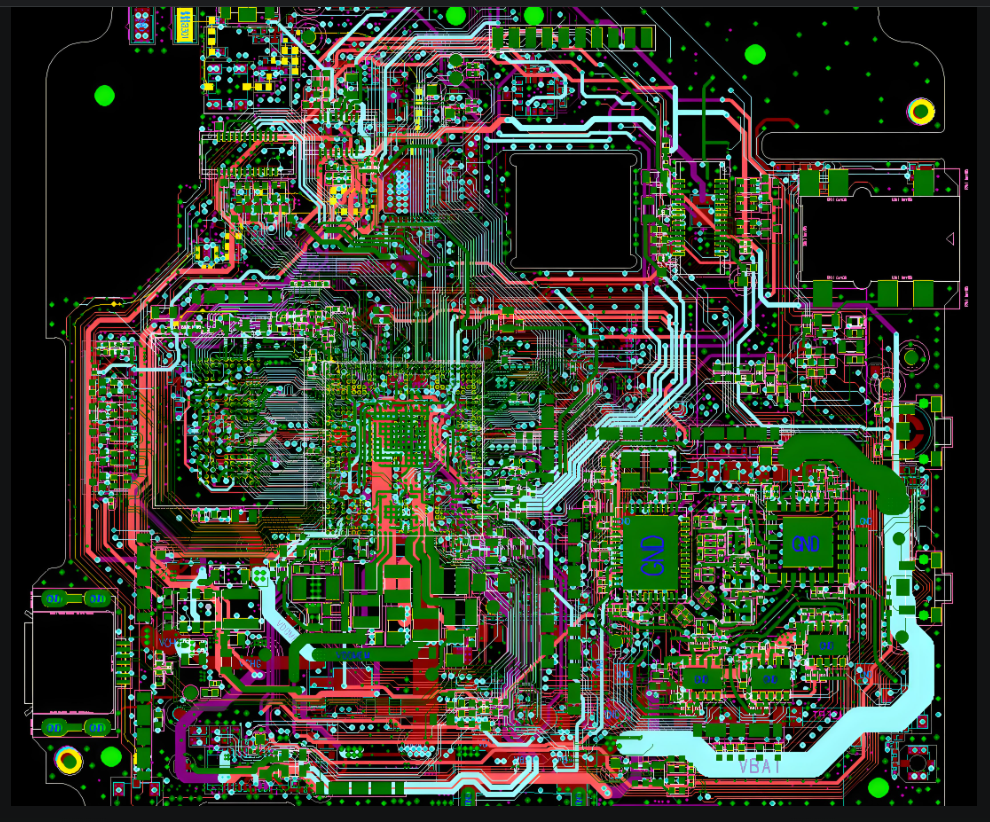

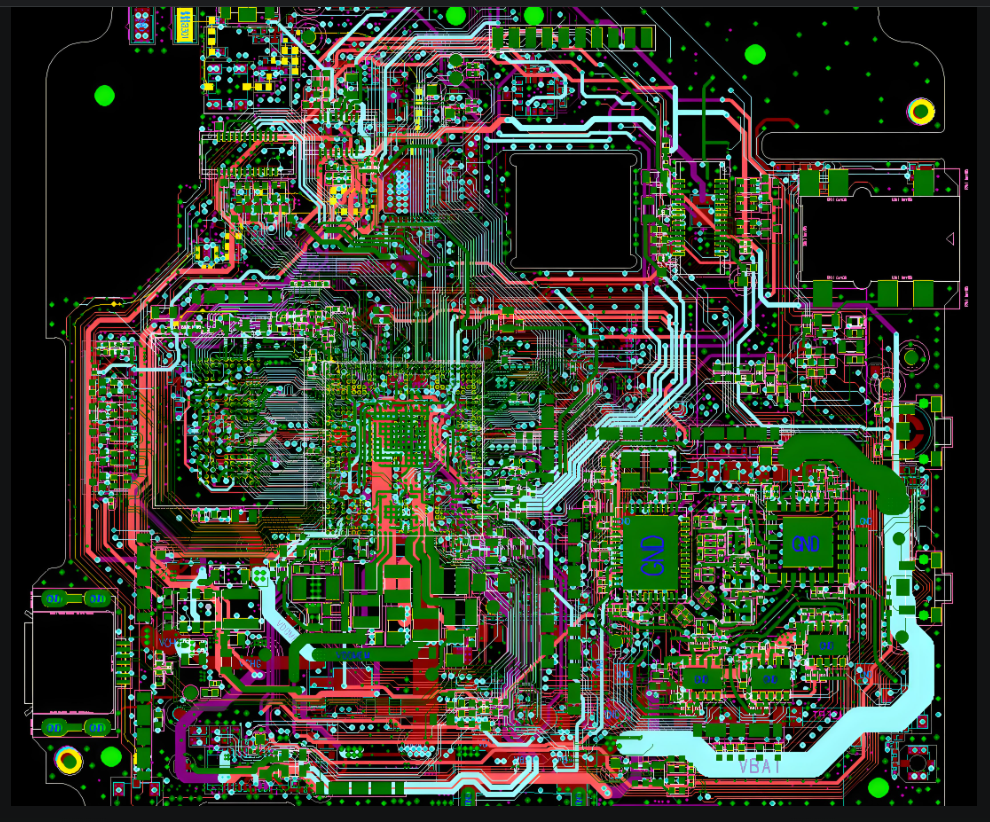

In addition to PCB manufacturing and PCBA assembly services, XDCPCBA also provides comprehensive PCB design services. This includes key links such as PCB layout design, PCB etching and circuit board design. Through a professional design team and advanced design software, XDCPCBA is able to provide customers with customized PCB design solutions to ensure that the elevator controller achieves the best balance in performance, size and cost.

In the PCB design process, XDCPCBA fully considers the actual application scenarios and special needs of elevator controllers. For example, during layout design, XDCPCBA will optimize the arrangement and routing of components to reduce signal interference and electromagnetic radiation; during etching, XDCPCBA will accurately control the etching depth and line width to ensure the conductivity and mechanical strength of the circuit board.

VI. Leaders in China's PCBA Manufacturing Industry

As a representative enterprise in China's PCBA manufacturing industry, XDCPCBA not only enjoys a high reputation in the domestic market, but also shows strong competitiveness in the international market. With advanced production equipment, superb process technology, strict quality control and high-quality service attitude, the company has won the trust and praise of many domestic and foreign customers.

In the field of elevator controller manufacturing, XDCPCBA relies on its rich experience and professional knowledge to provide customers with a one-stop solution. From PCB design and manufacturing to PCBA assembly and testing, XDCPCBA can provide customers with a full range of support and services. This not only reduces customers' production costs and time costs, but also improves product quality and market competitiveness.

VII. Summary and Outlook

From PCB to PCBA, the manufacturing process of elevator controllers is full of challenges and opportunities. As a leader in the PCB industry, XDCPCBA has successfully occupied an important position in the field of elevator controller manufacturing with its strong production capacity, advanced technology applications, strict quality control and high-quality service attitude. In the future, XDCPCBA will continue to uphold the principle of "quality first, customer first", continuously improve its own technical level and service quality, and provide more customers with more high-quality, efficient and reliable PCB and PCBA solutions. At the same time, XDCPCBA will also actively respond to the national call, promote the development of green manufacturing and intelligent manufacturing, and contribute to China's electronic manufacturing industry.