How to Choose a Reliable Printed Circuit Board Manufacturer: Key Considerations for Success

Choosing the right printed circuit board (PCB) manufacturer is a critical decision that can significantly impact the quality, cost, and timeline of

your electronics project. With so many options to choose from, identifying a reliable PCB manufacturer requires careful evaluation of several key factors. Whether you work in consumer electronics, automotive, medical devices, or another industry, working with a trusted manufacturer ensures that your PCBs meet the highest standards of performance and durability.

XDCPCBA supports free PCB prototyping 2-6 layer circuit boards, PCB assembly, 2-30 layer PCB PCBA manufacturing, PCB solutions, Component Sourcing service! sales@xdcpcba.com,+8618123677761

Key Points to Evaluate When Selecting a PCB Manufacturer

Industry Experience and Expertise

Look for a manufacturer with a proven track record in your specific industry. For example:

Medical Devices: Requires strict compliance with FDA regulations and precision in miniaturized designs.

Automotive: Requires rugged PCBs that can withstand harsh environmental conditions (e.g., AEC-Q200 compliance).

Aerospace: Avionics and satellite systems require high-reliability, high-frequency PCBs.

Manufacturers with extensive industry experience, like XDCPCBA, understand the unique challenges and compliance requirements of each industry.

Technical Capabilities

Make sure the manufacturer can handle the complexity of your project:

Layer count: From simple 2-6 layer PCBs for basic electronics to advanced 2-30 layer designs for high-density applications.

Technology: Capabilities in SMT (surface mount technology) assembly, HDI (high density interconnect), and flex/rigid-flex PCBs.

Turnkey solutions: PCBA fabricators (PCBA fabricators) that offer end-to-end services, including component sourcing, assembly, and testing.

Quality Assurance and Certifications

Reliable manufacturers prioritize quality control:

Compliance with IPC standards (e.g., IPC-6012, IPC-A-600).

Certifications such as ISO 9001, UL, RoHS, and REACH.

Advanced inspection tools (AOI, X-ray, flying probe testing) to detect defects early.

Production Capacity and Scalability

Choose a manufacturer that can scale with your needs:

Prototype to production capabilities for a seamless transition.

Flexible production lines to accommodate small or large batch orders.

Fast turnaround time without compromising quality.

Customer Support and Communication

Effective collaboration is key:

Responsive technical support to optimize designs.

Open communication channels during production.

Assistance with troubleshooting or modifications after delivery.

Cost and Value

While pricing is important, prioritize value over lowest bid:

Request detailed quotes to avoid hidden costs.

Evaluate long-term reliability vs. short-term savings.

PCB Applications Across Industries

PCBs are an integral part of modern technology, enabling innovation in the following areas:

Consumer Electronics: Smartphones, Wearables, and IoT devices.

Automotive: Electric vehicles, ADAS, and infotainment systems.

Medical: Diagnostic equipment, patient monitoring, and portable devices.

Industrial Automation: Robotics, sensors, and control systems.

Aerospace: Avionics, satellites, and communication systems.

Telecom: 5G infrastructure, data centers, and network equipment.

Why XDCPCBA is your trusted partner

At XDCPCBA, we combine technical excellence with a customer-centric approach to deliver reliable PCB solutions. As a leading PCB assembly factory (PCB assembly factory) and PCBA manufacturer (PCBA manufacturer), we specialize in:

SMT PCB assembly (SMT PCB assembly): Precise placement of surface mount components for optimal performance.

2-30 layer PCB manufacturing: From standard 2-6 layer boards to complex 30 layer designs.

Free 2-6 layer PCB samples: Test your prototypes risk-free with our free sample service.

Turnkey Electronics Contract Manufacturing: As an Electronics Contract Manufacturer (electronics contract manufacturer), we handle everything from design to delivery.

Why choose XDCPCBA?

Industry-specific expertise: Tailor-made solutions for automotive, medical, aerospace, and more.

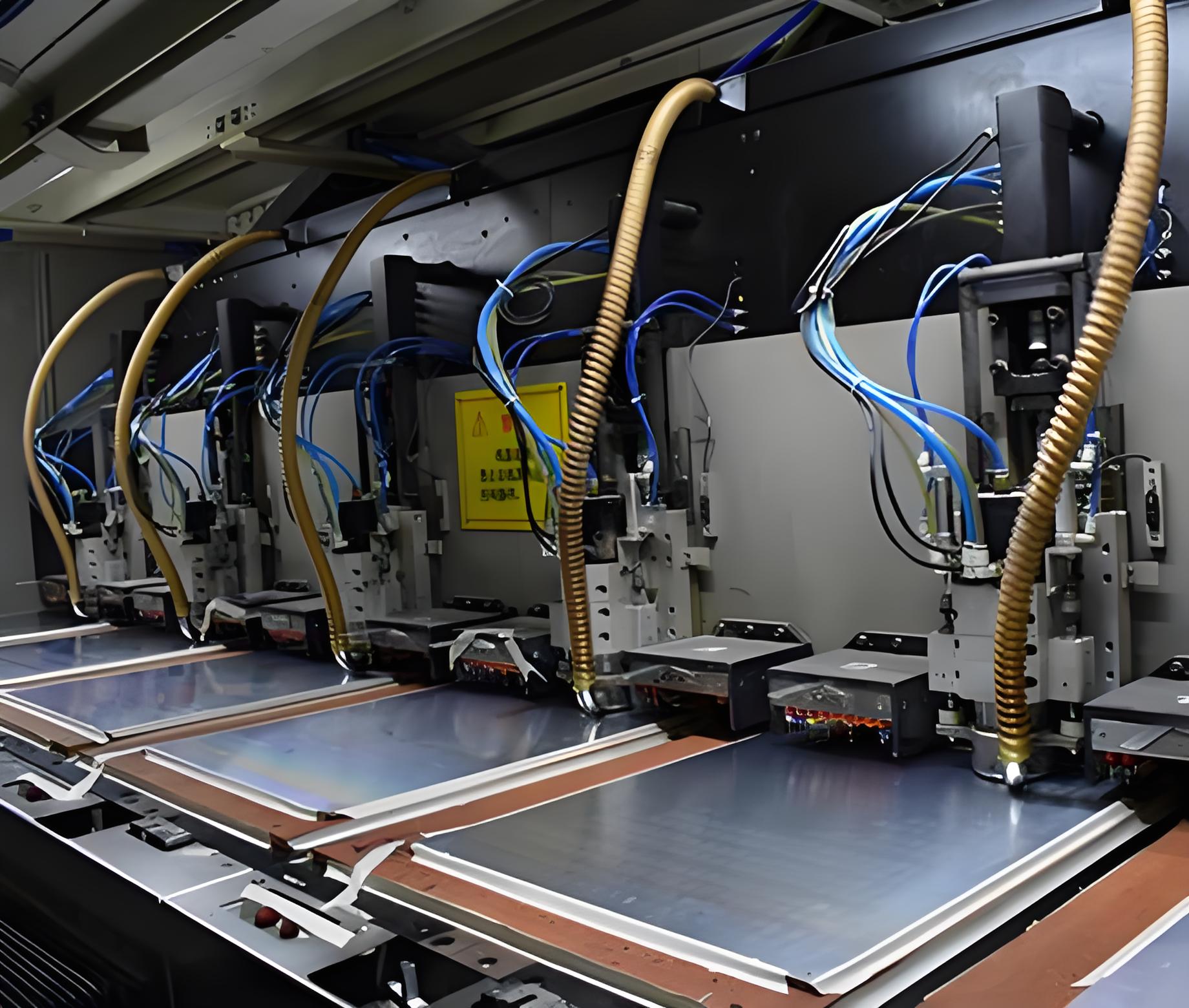

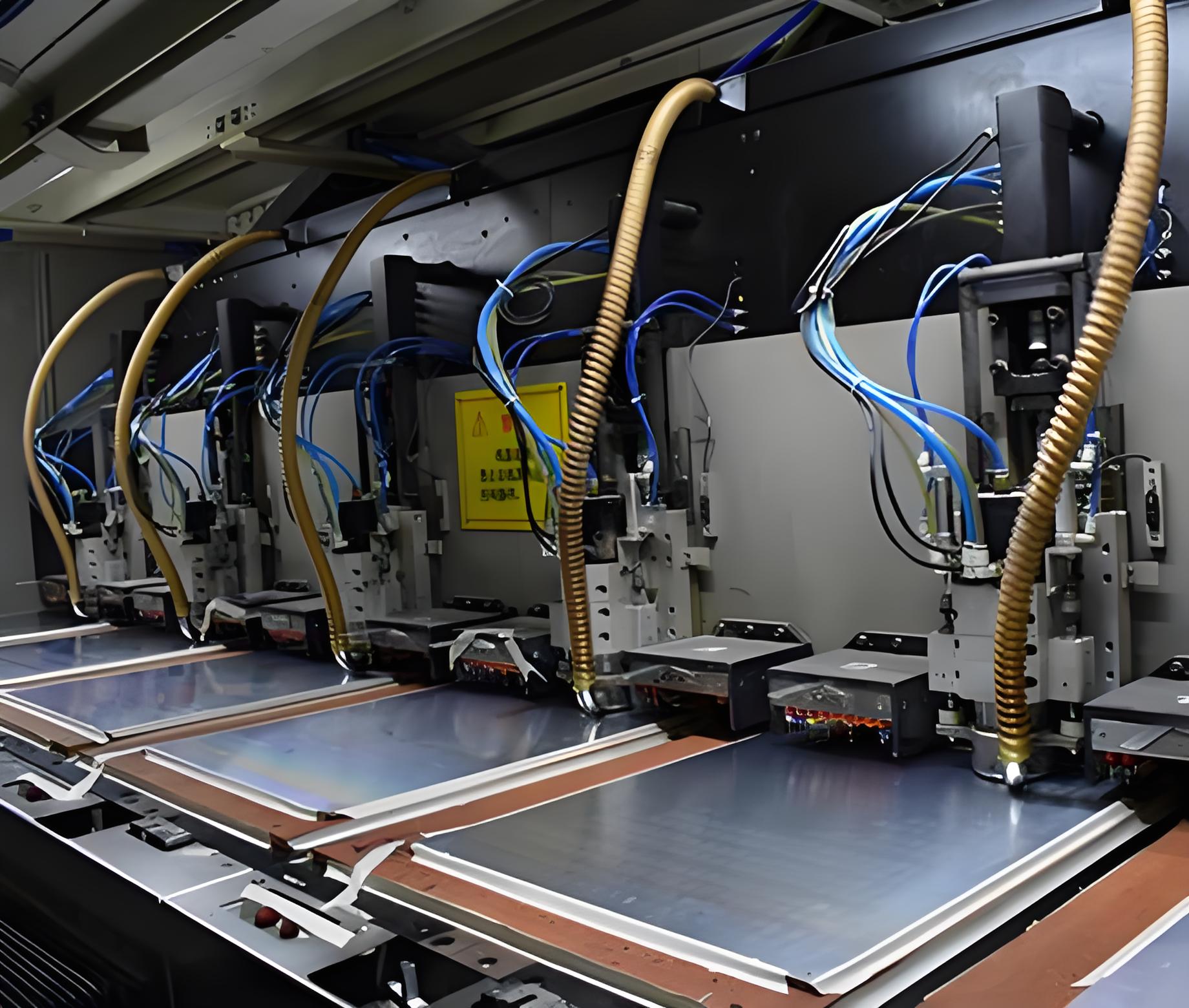

Advanced technology: Advanced equipment for HDI, flexible PCBs, and rigid-flex assemblies.

Quality assurance: Rigorous testing and IPC-compliant processes ensure defect-free products.

Global compliance: RoHS, UL, and ISO certifications ensure worry-free production.

Take the Next Step with XDCPCBA

Whether you need a prototype for a new IoT device or volume production of automotive sensors, XDCPCBA is your go-to PCB supplier (PCB Supplier). Our 2-6 layer PCB free prototyping service (Free 2-6 layer PCB prototyping service) allows you to validate your design before scaling up, reducing risk and accelerating innovation.

Partner with XDCPCBA - reliability, precision, and industry expertise come together to power your success. Contact us today to discuss your PCB needs!

XDCPCBA: Your trusted source for SMT PCB assembly, multi-layer PCB manufacturing, and turnkey electronic solutions.