Improving the reliability of elevator controllers: Comparison of PCBA assembly and processing technologies

In today's highly modernized society, elevators are important tools for vertical transportation, and their safety and reliability are directly related to the safety of people's lives and property and the convenience of daily life. As the "brain" of the elevator system, the stability and reliability of the performance of the elevator controller are particularly critical. The core of the elevator controller is the printed circuit board assembly (PCBA) part inside it. This article will explore the PCBA assembly and processing technology in depth, compare the advantages and disadvantages of different technical routes, and introduce XDCPCBA as a leading provider in the PCB industry. Unique advantages in improving the reliability of elevator controllers.

Overview of PCBA assembly technology

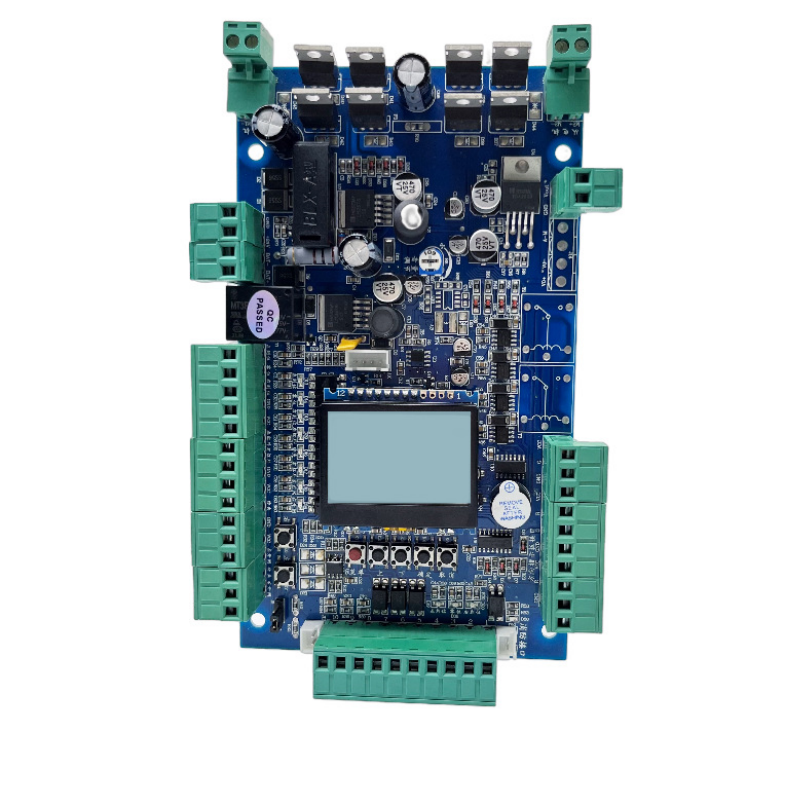

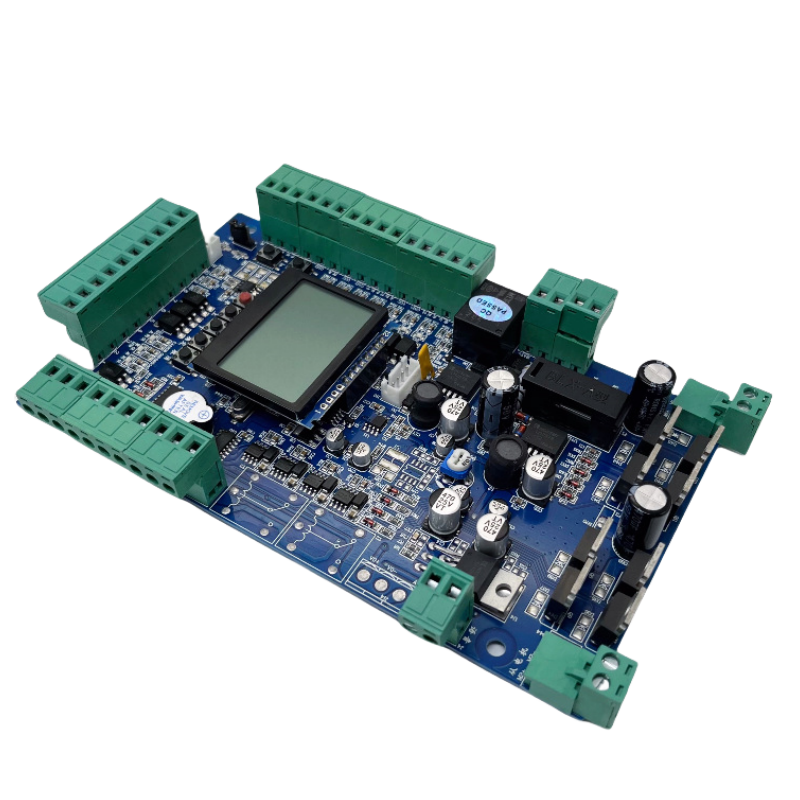

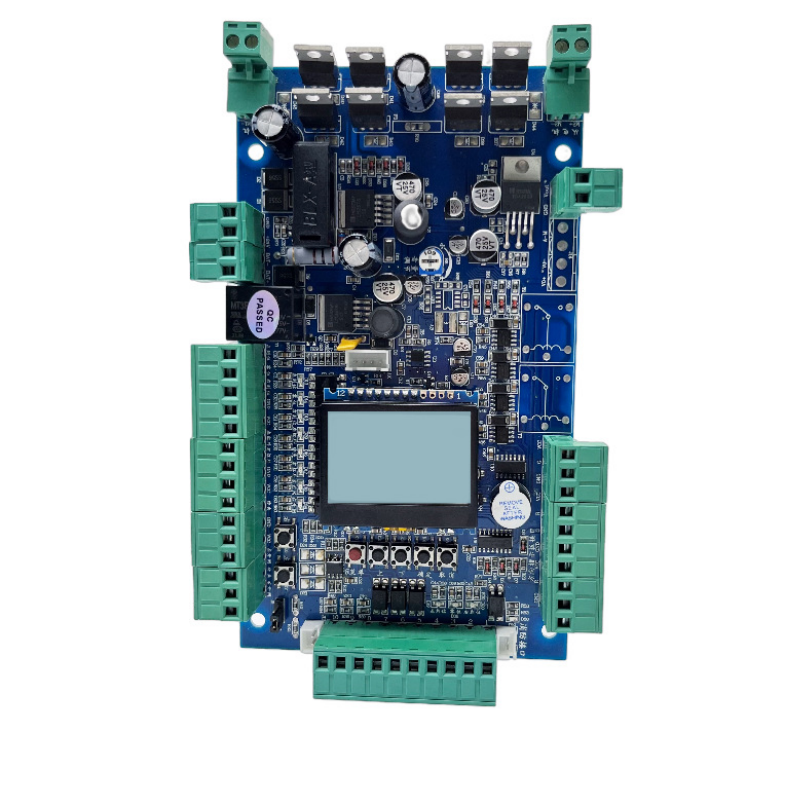

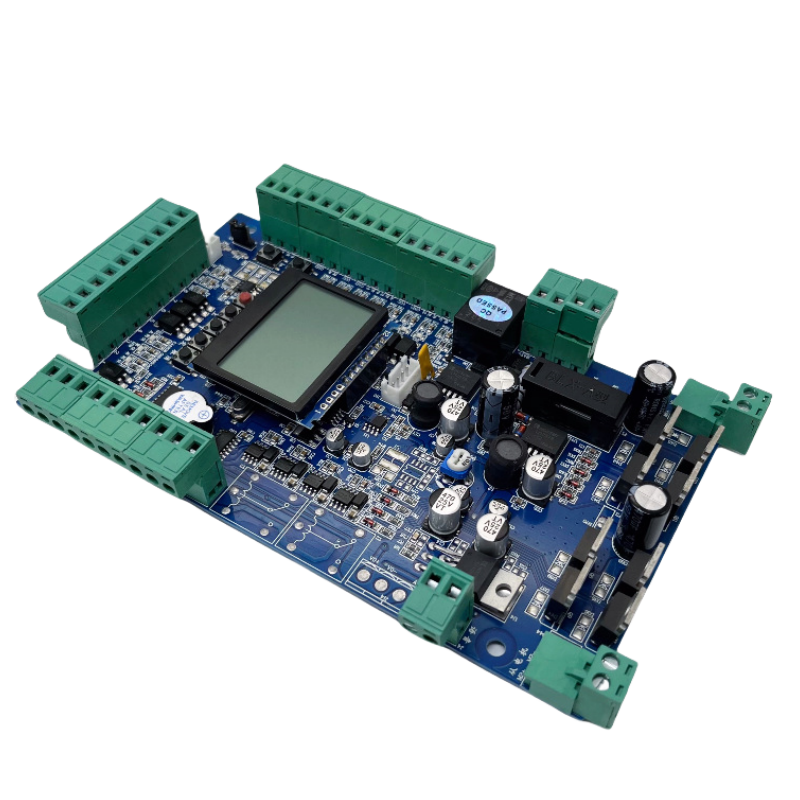

PCBA (Printed Circuit Board Assembly) is the installation of electronic components on printed circuit boards through welding, plug-in, etc. to form electronic modules or systems with specific functions. In the elevator controller, PCBA is responsible for processing various signals, controlling the operating status of the elevator, and ensuring the safety and stability of the elevator under various working conditions.

PCBA assembly technology mainly includes surface mount technology (SMT), plug-in technology (THT) and their combined applications. With the continuous development of electronic technology, SMT technology has gradually become the mainstream due to its advantages such as small size, light weight, high assembly density and good reliability. However, in certain specific occasions, such as when components need to withstand greater mechanical stress or higher power, THT technology still plays an irreplaceable role.

Comparison of SMT and THT technology

Surface mount technology (SMT)

SMT technology is to directly mount electronic components on the surface of the printed circuit board, and realize the electrical and mechanical connection between the components and the circuit board through processes such as reflow soldering. The advantages of SMT technology are:

Small size and light weight: The volume and weight of SMT components are much smaller than traditional plug-in components, which greatly reduces the volume and weight of electronic products.

High assembly density: SMT technology can arrange more components on a limited circuit board space, improving the integration and function of electronic products.

Good reliability: The connection between SMT components and circuit boards is more solid, and they have strong vibration and impact resistance, which improves the reliability of electronic products.

In elevator controllers, SMT technology is widely used in circuit parts such as processing signals and control logic, making elevator controllers more compact and reliable.

Plug-in Technology (THT)

THT technology is to insert the pins of electronic components into the sockets of printed circuit boards, and realize the electrical and mechanical connection between components and circuit boards through processes such as wave soldering. The advantages of THT technology are:

High mechanical strength: The pins of plug-in components are inserted into the sockets of the circuit board, forming a more solid mechanical connection, which is suitable for occasions with greater mechanical stress.

Strong power handling capability: THT components usually have a larger volume and heat dissipation area, and can better handle high-power signals.

In elevator controllers, THT technology is mainly used for power amplification, power management and other circuit parts that need to withstand greater power or mechanical stress.

XDCPCBA: Leader in PCBA Assembly Technology

As a leading provider in the PCB industry, XDCPCBA is not only good at PCB manufacturing, but also has deep strength and rich experience in PCBA assembly. XDCPCBA has its own PCB factory, focusing on the production of high-quality PCBs with 2 to 30 layers, demonstrating its strong production capacity and deep understanding of customer needs.

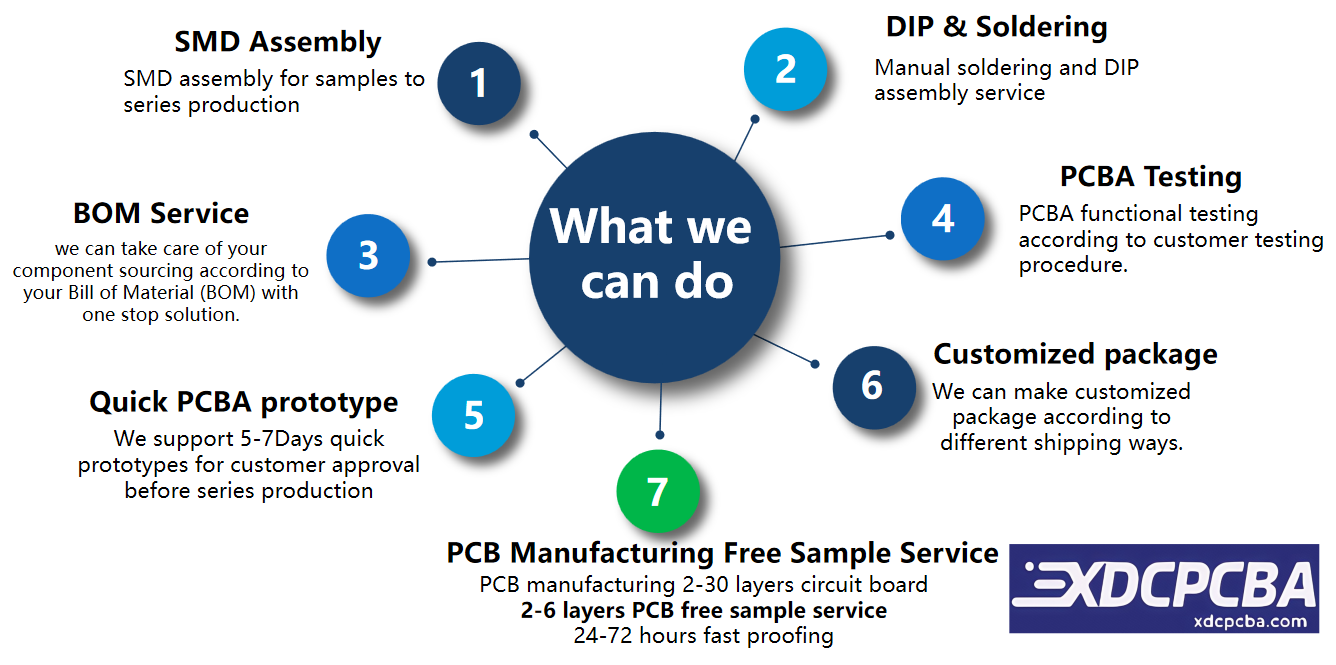

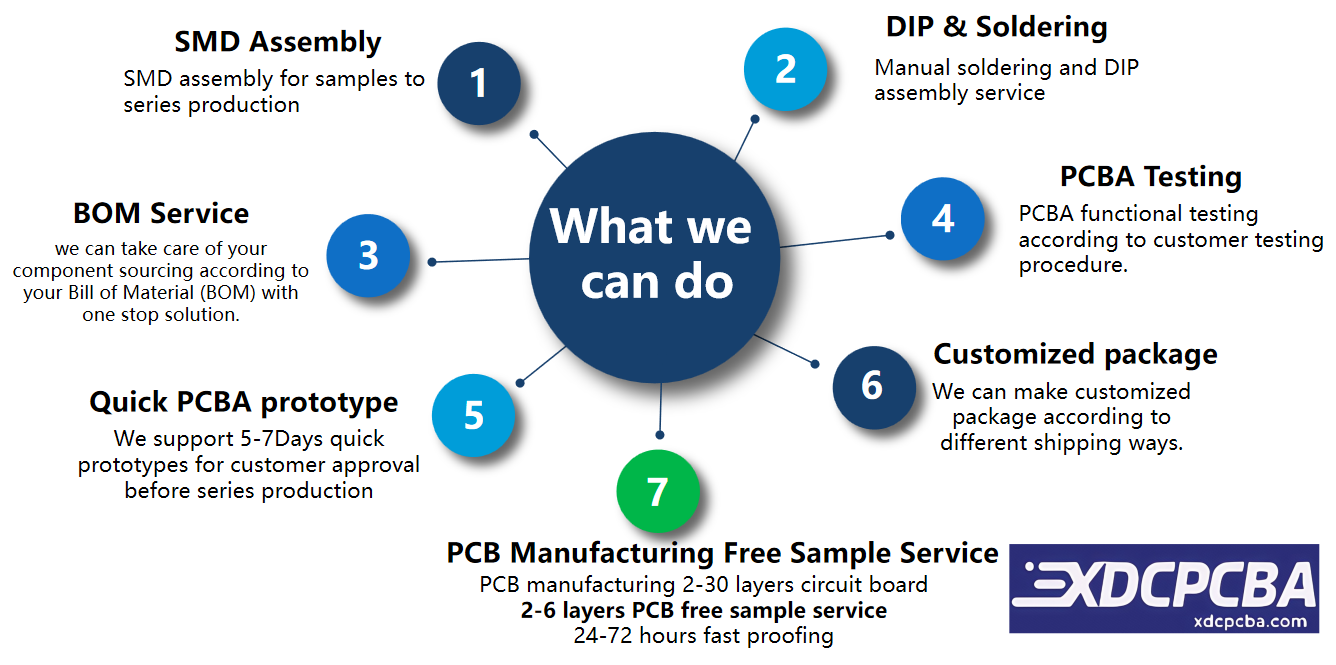

Comprehensive PCBA Processing Services

XDCPCBA's PCB assembly factory provides comprehensive PCBA processing services, including SMT assembly, SMD assembly and electronic assembly. These services cover multiple industries such as industrial automation, automotive electronics, communication equipment, Internet of Things, mechanical equipment, instrumentation, power equipment, medical equipment, aerospace, power supply electrical, home appliances and consumer electronics. No matter what type of PCBA assembly service the customer needs, XDCPCBA can provide solutions to meet their needs.

Advanced Assembly Technology and Equipment

XDCPCBA uses advanced assembly technology and equipment, such as fully automatic placement machines, reflow soldering machines, wave soldering machines, etc., to ensure the accuracy and reliability of PCBA assembly. At the same time, XDCPCBA has also established a complete testing and quality control system to strictly inspect and test each assembled PCBA to ensure that its electrical performance, mechanical performance and environmental adaptability meet the highest standards.

Professional PCB Design Services

In addition to PCBA assembly services, XDCPCBA also provides professional PCB design services. The company has an experienced PCB design team that can perform PCB layout design, PCB etching and circuit board design according to customer needs. XDCPCBA is well aware of the importance of material selection to PCB performance, so it provides a variety of circuit board material options for different applications, such as high Tg materials, low dielectric constant materials, etc., to meet customers' special requirements for PCB performance.

Free Sample Service and Customer Satisfaction

In order to further improve customer satisfaction, XDCPCBA has also launched a free sample service. For PCBs with 2 to 6 layers, customers can get free samples provided by XDCPCBA for testing and verifying their designs. This move not only demonstrates XDCPCBA's attention to customer needs, but also reflects the company's confidence in product quality and service.

Application of XDCPCBA in Elevator Controllers

In the manufacturing process of elevator controllers, XDCPCBA provides high-quality and reliable PCBA solutions for elevator controllers with its comprehensive PCBA processing services and advanced assembly technology. Whether it is SMT assembly or THT assembly, XDCPCBA can provide the most optimized solution according to customer needs.

For the SMT assembly part, XDCPCBA uses high-precision placement machines and reflow soldering machines to ensure accurate placement and firm connection of components. At the same time, through strict testing and quality control measures, the electrical performance and reliability of the SMT assembly part are ensured.

For the THT assembly part, XDCPCBA uses wave soldering machines and other equipment to achieve a firm connection between components and circuit boards. At the same time, XDCPCBA also provides special solutions and optimization suggestions for mechanical stress and power handling problems that may be encountered in elevator controllers.

Conclusion: Choose XDCPCBA to improve the reliability of elevator controllers

As a leader in electronic manufacturing service providers and electronic contract manufacturers, XDCPCBA has demonstrated unique advantages in improving the reliability of elevator controllers with its comprehensive PCBA processing services, advanced assembly technology and equipment, and professional PCB design services. The company not only provides one-stop services from PCB design to assembly, but also is committed to meeting the diverse needs of customers to ensure that each PCBA has high precision, high reliability and long life.

For elevator manufacturers, choosing XDCPCBA as a PCBA processing plant and supplier is undoubtedly a wise move. XDCPCBA will provide strong support for the manufacture of elevator controllers with its excellent product quality and service level. At the same time, as a leading Chinese PCBA manufacturer and supplier, XDCPCBA will continue to uphold the core concepts of innovation, quality and service and contribute to the development of the global electronics manufacturing industry. In the future development, XDCPCBA will continue to be committed to improving the reliability of elevator controllers and providing safer and more convenient solutions for people's vertical transportation.