PCB Manufacturing Basics: The Key to Building High-Quality Elevator Controllers

In today's rapidly developing technological era, elevators are an indispensable means of transportation in modern buildings, and their safety and reliability are of vital importance. The performance of elevator controllers is one of the core factors that determine the quality of elevator operation. A high-quality elevator controller is inseparable from the exquisite craftsmanship and excellent performance of its internal printed circuit board (PCB). This article will delve into the basics of PCB manufacturing and introduce XDCPCBA's unique advantages in building high-quality elevator controllers as a leading provider in the PCB industry.

The Basics and Importance of PCBs

Printed circuit boards, or PCBs for short, are carriers used to connect electronic components in electronic devices. It achieves electrical connections between electronic components by precisely arranging copper foil lines, pads, vias and other elements on an insulating substrate. PCBs not only carry the "neural network" of electronic devices, but also bear the functions of mechanical support and heat dissipation. Therefore, the quality and performance of PCBs directly affect the reliability and stability of the entire electronic device.

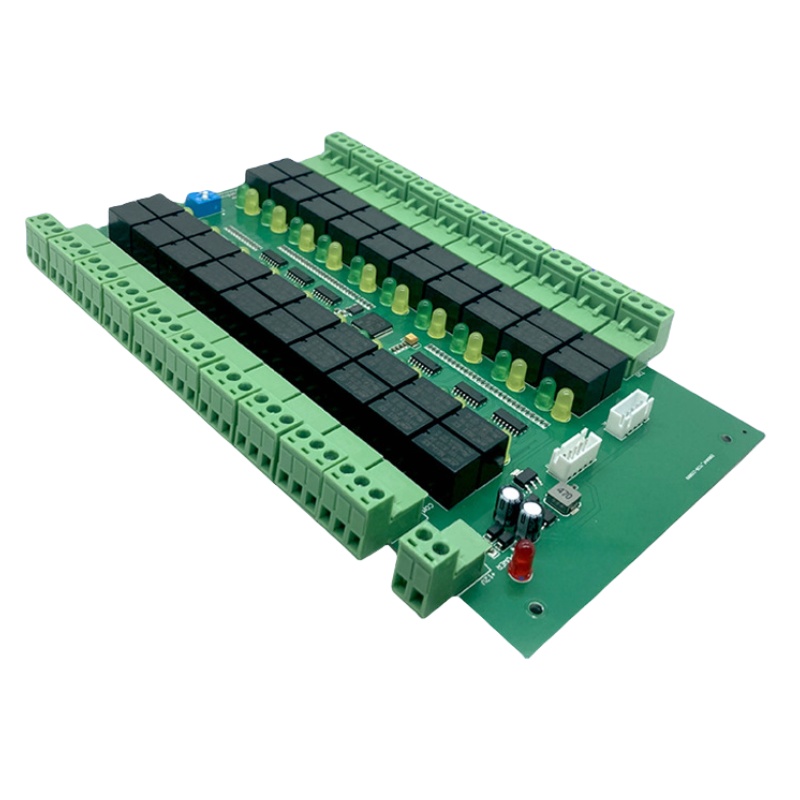

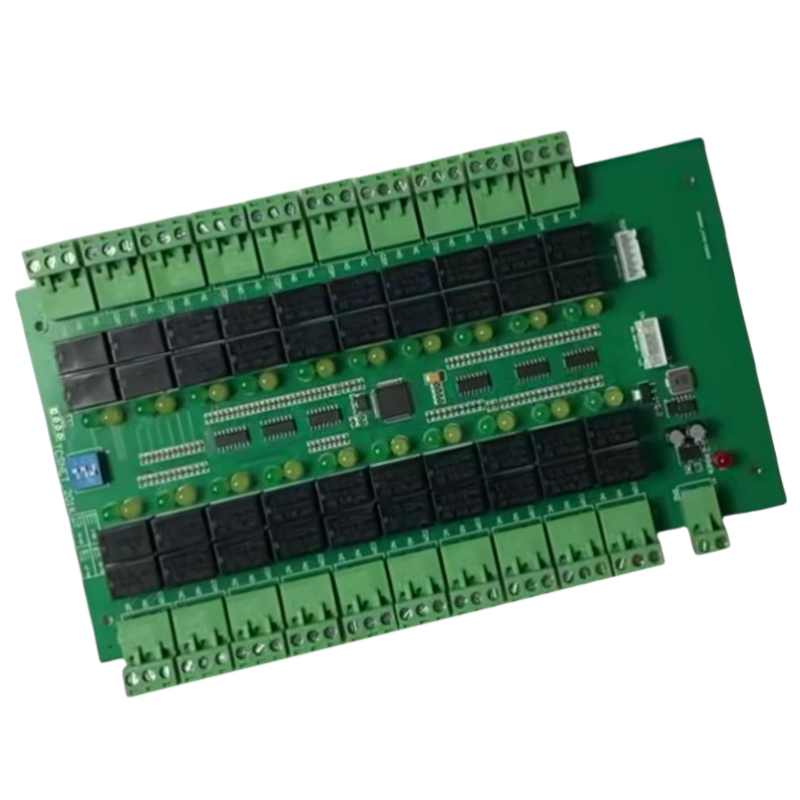

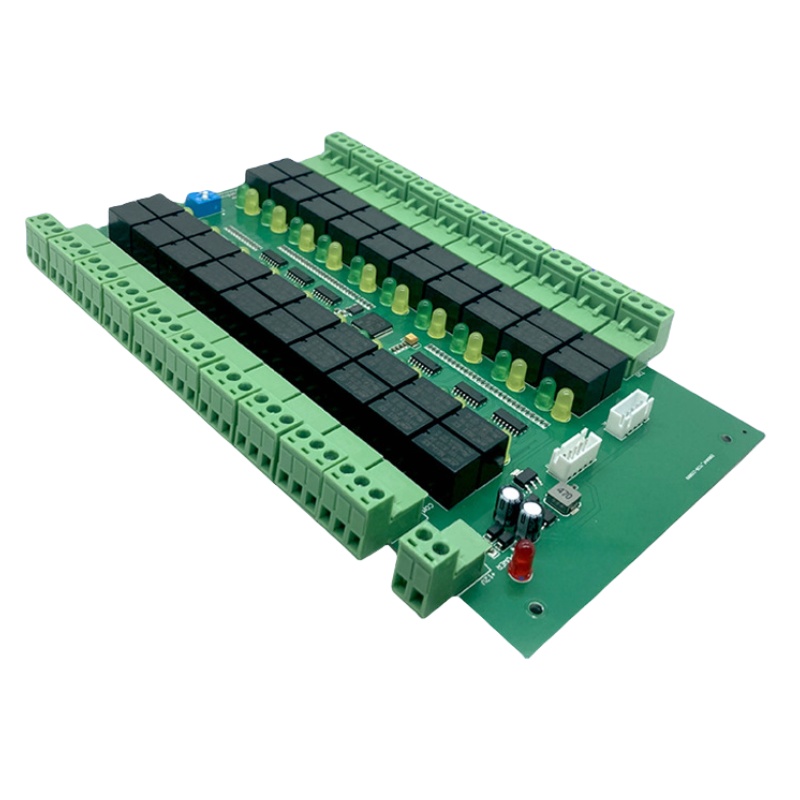

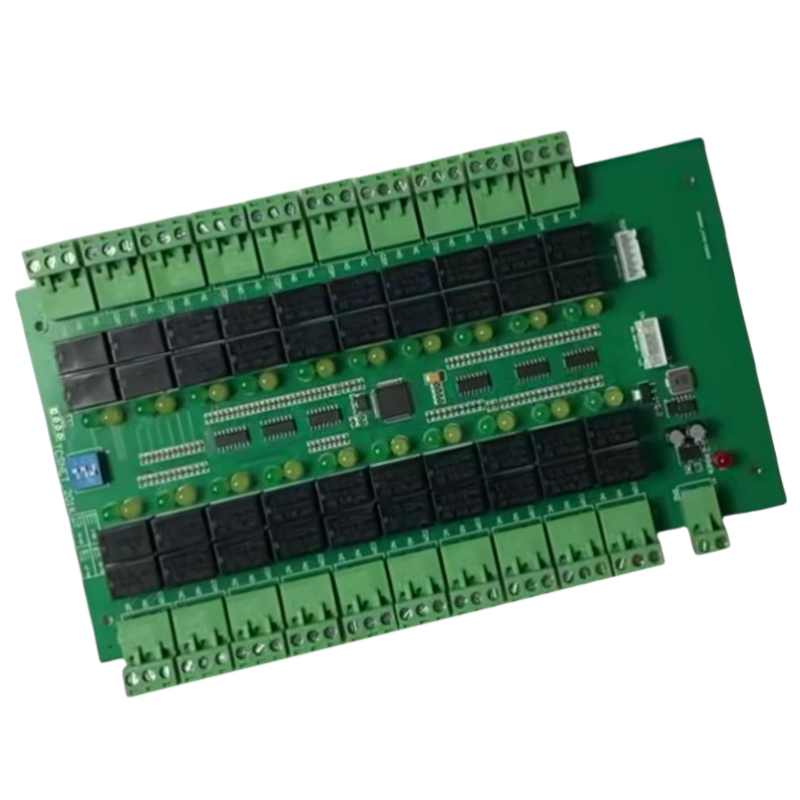

In elevator controllers, PCBs also play a vital role. Elevator controllers need to process a large amount of signals and data, including speed control, position detection, safety protection, etc. The realization of these functions is inseparable from the complex and precise circuit layout on PCBs. A well-designed and well-made PCB can ensure that the elevator controller can operate stably under various working conditions, thereby ensuring the safety of the elevator and the comfort of passengers.

XDCPCBA: A leading provider in the PCB industry

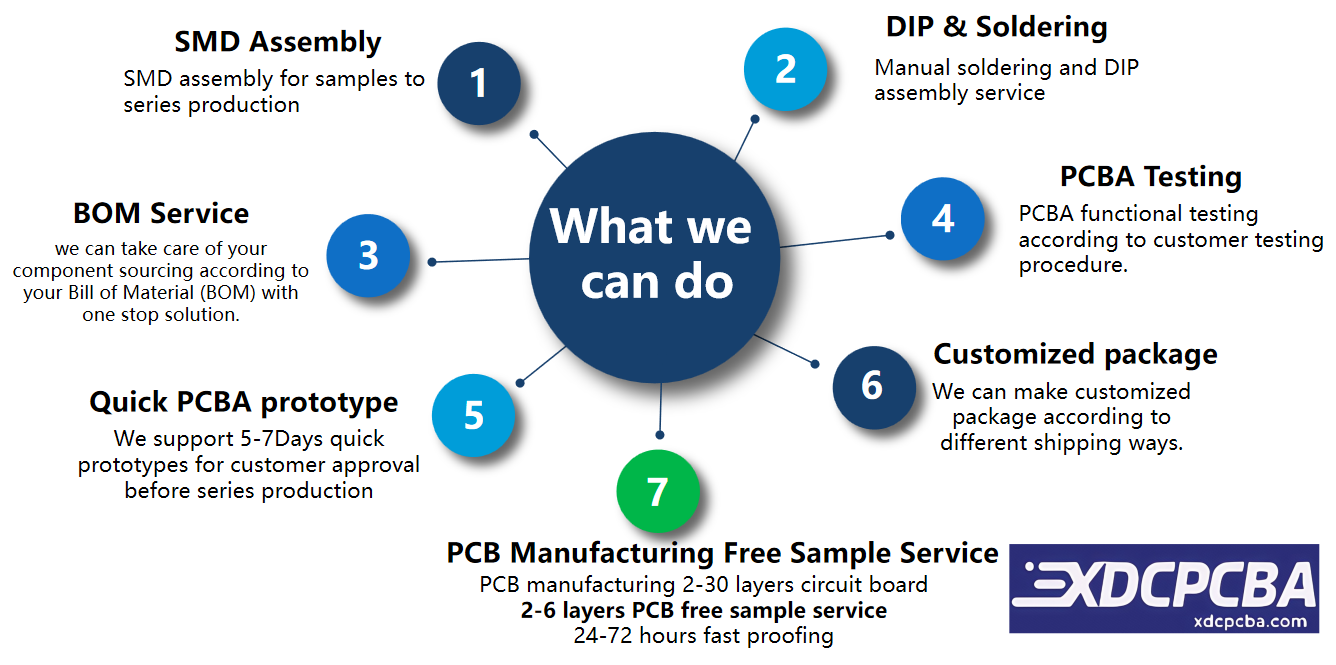

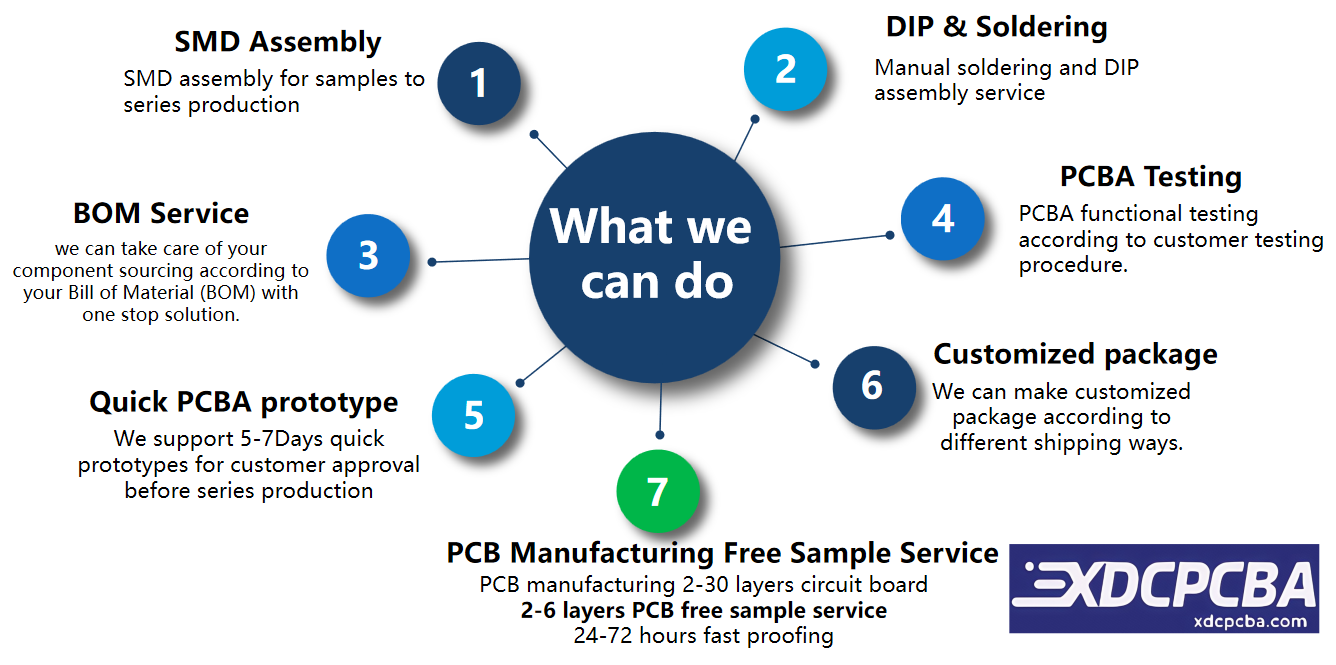

As a leader in the PCB industry, XDCPCBA enjoys a high reputation in the field of electronic equipment manufacturing such as elevator controllers with its comprehensive capabilities and deep industry experience. XDCPCBA not only has its own PCB factory, but also provides one-stop services from PCB manufacturing to PCB assembly.

Comprehensive PCB manufacturing capabilities

XDCPCBA excels in producing various types of PCBs from 2 to 30 layers, including double-sided PCBs, multi-layer PCBs, high-frequency PCBs, HDI PCBs, rigid-flex PCBs, aluminum-based PCBs, prototype PCBs, flexible PCBs, ceramic PCBs, large-size PCBs, and copper-based PCBs. The company uses advanced PCB manufacturing technology to ensure that each PCB has high precision and reliability. This comprehensive manufacturing capability enables XDCPCBA to meet the diverse needs of complex electronic equipment such as elevator controllers for PCBs.

Professional PCBA manufacturing services

In addition to PCB manufacturing, XDCPCBA is also an excellent PCBA manufacturer. Its PCB assembly factory provides a full range of PCBA processing services including SMT assembly, SMD assembly and electronic assembly. These services are widely used in many industries such as industrial automation, automotive electronics, communication equipment, Internet of Things, mechanical equipment, instrumentation, power equipment, medical equipment, aerospace, power electrical, home appliances and consumer electronics.

In particular, XDCPCBA launched a free sample service for PCBs with 2 to 6 layers. This move not only demonstrates the company's commitment to customer satisfaction, but also provides customers with a convenient way to test and verify PCB designs.

Advanced PCB Design and Prototyping

XDCPCBA not only excels in PCB manufacturing and assembly, but also provides professional PCB design services. This includes PCB layout design, PCB etching and circuit board design. The company is well aware of the importance of material selection to PCB performance, so it provides a variety of circuit board material options for different applications. In addition, XDCPCBA can also provide prototype PCB board production services and affordable PCB production solutions according to customer needs.

The key to creating high-quality elevator controllers

In the manufacturing process of elevator controllers, the quality and performance of PCBs are crucial. Here are some key aspects of how XDCPCBA ensures that elevator controller PCBs meet high quality standards:

Precise design:

XDCPCBA has a professional PCB design team that can perform precise circuit design and layout according to the specific needs of the elevator controller.

The design process fully considers factors such as signal integrity, power integrity, and thermal management to ensure that the PCB can operate stably under harsh working conditions.

High-quality materials:

XDCPCBA provides a variety of high-performance circuit board material options, such as high Tg materials, low dielectric constant materials, etc., to meet the special requirements of elevator controllers for temperature resistance, voltage resistance, and signal transmission performance.

Exquisite manufacturing technology:

The company uses advanced PCB manufacturing equipment and technology, such as laser drilling, automatic electroplating lines, etc., to ensure the accuracy and reliability of PCBs.

Strict quality control system, strict inspection and testing of each PCB, to ensure that product quality meets international standards.

Professional assembly service:

XDCPCBA's PCB assembly factory is equipped with advanced SMT and SMD assembly equipment, which can provide efficient and precise electronic component placement services.

Perfect testing and quality control measures ensure that the assembled elevator controller PCB has excellent electrical performance and mechanical stability.

Customized solutions:

XDCPCBA can provide customized PCB design and manufacturing solutions according to the specific needs of customers.

Whether it is small-batch prototyping or mass production, XDCPCBA can provide economical, efficient and reliable solutions.

Conclusion

As a leader in electronic manufacturing service providers and electronic contract manufacturers, XDCPCBA has demonstrated unique advantages in creating high-quality elevator controllers with its comprehensive PCB manufacturing capabilities, professional PCBA manufacturing services, and advanced PCB design and prototyping technologies. The company not only provides one-stop services from PCB design to assembly, but also is committed to meeting the diverse needs of customers to ensure that each PCB has high precision, high reliability and long life.

For elevator manufacturers, choosing XDCPCBA as a supplier of PCBs and PCBAs is undoubtedly a wise move. With its excellent product quality and service level, XDCPCBA will provide strong support for the manufacturing of elevator controllers and help the elevator industry move towards a safer, more efficient and intelligent future. At the same time, as a leading Chinese PCBA manufacturer and supplier, XDCPCBA will continue to uphold the core concepts of innovation, quality and service and contribute to the development of the global electronics manufacturing industry.