The road to innovation of elevator controllers: exploring the latest progress in PCBA processing technology

In the manufacturing field of elevator controllers, technological innovation is the core driving force for the development of the industry. As the core component of the elevator control system, the performance and stability of the elevator controller are directly related to the safety and efficiency of the elevator. As a key link in the manufacturing of elevator controllers, the latest progress of PCBA (printed circuit board assembly) processing technology has a profound impact on the innovation and development of elevator controllers. XDCPCBA, as a leading provider of printed circuit boards (PCB) industry, is leading the innovation of elevator controller PCBA processing technology with its comprehensive capabilities from PCB manufacturing to PCB assembly services.

1. XDCPCBA: The leader of the PCB industry

XDCPCBA, as a leader in the PCB industry, not only has its own PCB factory, but also focuses on the production of high-quality PCBs with 2 to 30 layers, demonstrating its strong production strength and deep understanding of diverse customer needs. The company provides a wide range of PCB products, including double-sided PCB, multi-layer PCB, high-frequency PCB, HDI PCB, rigid-flex PCB, aluminum substrate PCB, prototype PCB, flexible PCB, ceramic PCB, large-size PCB and copper-based PCB, etc., to meet the diverse needs of different industries for PCBs.

XDCPCBA is well aware of the importance of material selection to PCB performance, so it provides a range of circuit board materials for specific applications. In addition, the company also provides PCB design services, covering PCB layout design, PCB etching and circuit board design, etc., providing customers with a full range of solutions from design to production. This one-stop service not only improves production efficiency, but also ensures product consistency and reliability.

XDCPCBA also excels in PCBA processing. As a professional PCBA manufacturer and electronic contract manufacturer, the company provides a wide range of PCBA processing services, including SMT assembly, SMD assembly and electronic assembly. These services cover a number of industries such as industrial automation, automotive electronics, communication equipment, Internet of Things, mechanical equipment, instrumentation, power equipment, medical equipment, aerospace, power electrical, home appliances and consumer electronics. Through strict testing and quality control measures, XDCPCBA ensures the highest standards for each PCBA product.

It is particularly worth mentioning that XDCPCBA also provides free sample services for 2 to 6-layer PCBs, which fully demonstrates the company's commitment to customer satisfaction. This customer-centric service concept has enabled XDCPCBA to stand out in the fierce market competition and win the trust and support of customers.

2. The latest progress in PCBA processing technology

With the continuous development of science and technology, PCBA processing technology is also constantly innovating and improving. These latest developments not only improve the manufacturing efficiency and product quality of elevator controllers, but also provide strong support for the intelligence, miniaturization and high performance of elevator controllers.

Wide application of automation and intelligent technology

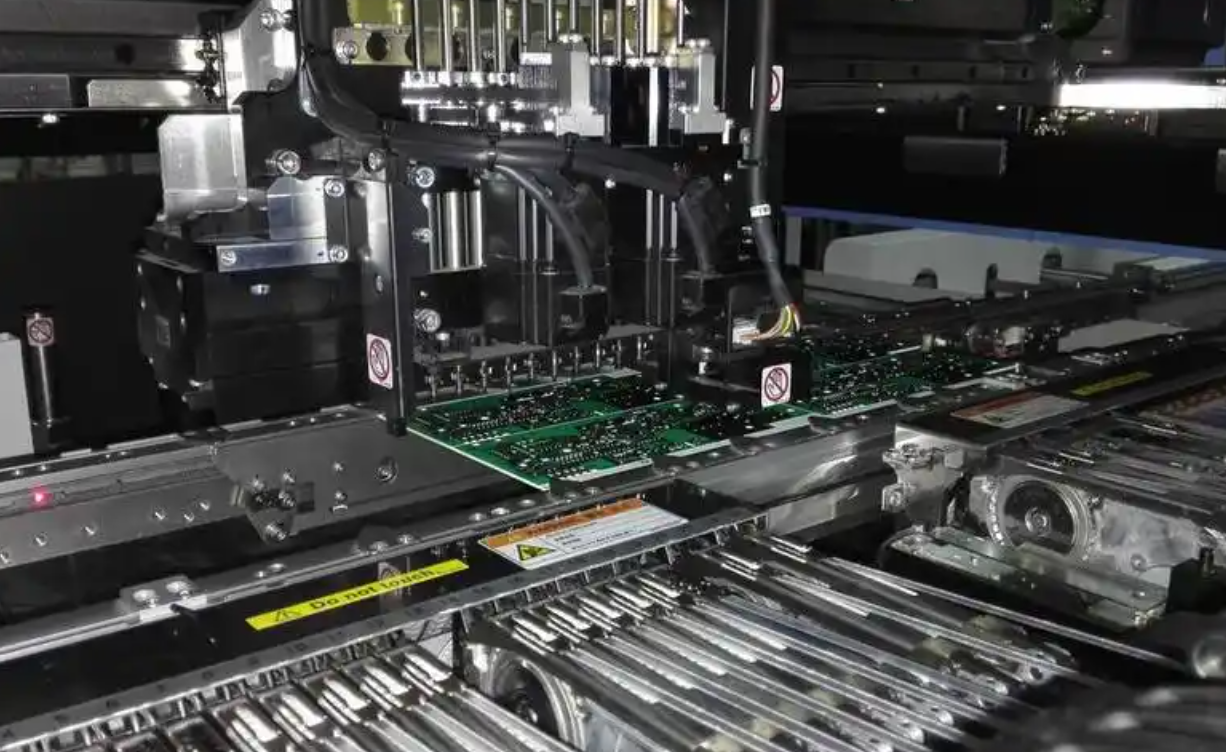

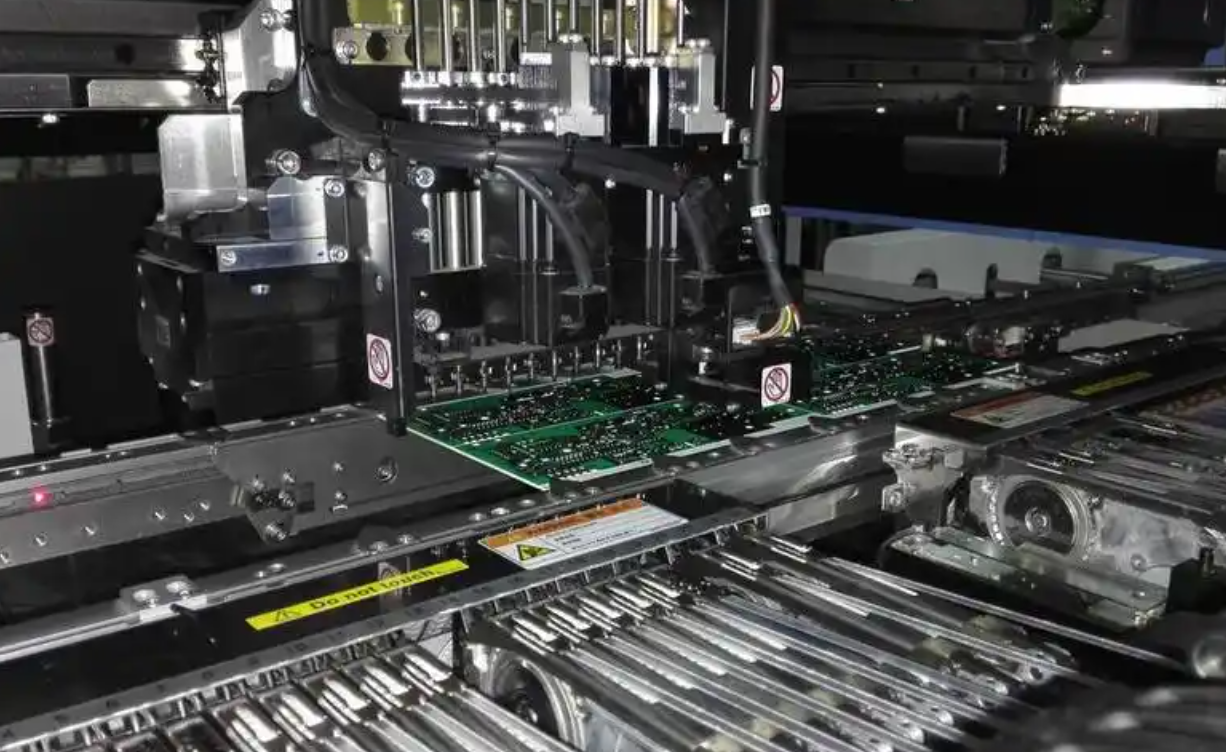

In the PCBA processing process, the application of automation and intelligent technology has become a trend. XDCPCBA has introduced advanced automated placement machines and intelligent management systems, which have greatly improved production efficiency and placement accuracy. These automated equipment can quickly and accurately identify and mount various components, reduce errors caused by human factors, and improve product consistency and reliability.

With the help of artificial intelligence and big data analysis technology, XDCPCBA has achieved real-time monitoring and optimization of the production process. By collecting and analyzing production data, the company can promptly discover and solve potential problems and reduce production risks and costs. This concept of intelligent manufacturing not only improves production efficiency, but also provides data support for subsequent maintenance and management.

Application of new welding process

Welding is one of the key links in PCBA processing. Traditional welding processes are prone to problems such as poor welding and cold welding when dealing with tiny components and high-density circuit boards. XDCPCBA has successfully applied laser welding technology to PCBA manufacturing, effectively solving these problems. Laser welding technology has the characteristics of high precision and low heat input, and can achieve more delicate welding operations. When processing tiny components in elevator controllers, laser welding can accurately control the welding points, reduce the impact of thermal stress on components and circuit boards, and greatly improve the welding quality and reliability.

In addition, XDCPCBA has also conducted in-depth research and optimization on lead-free welding processes. By adjusting the welding temperature curve, optimizing the flux formula, and improving the parameters of welding equipment, the company has solved the common problems of poor wettability and insufficient solder joint strength in the lead-free welding process. At the same time, XDCPCBA has also introduced advanced welding quality detection equipment, such as X-ray detection and ultrasonic detection, to conduct comprehensive inspections of lead-free solder joints to ensure that product quality meets international environmental standards and industry requirements.

Application of 3D stereoscopic layout technology

In order to meet the needs of miniaturization and multifunctionality of elevator controllers, XDCPCBA innovatively applied 3D stereoscopic layout technology. Traditional PCB layout is mainly carried out on a two-dimensional plane, while 3D stereoscopic layout technology allows components to be stacked and distributed on different levels of the circuit board, effectively saving circuit board space. In the PCBA design of the elevator controller, XDCPCBA stacks some chips and passive components in three dimensions, which not only reduces the circuit board area, but also improves the signal transmission efficiency and system integration.

The introduction of efficient heat dissipation design solutions

For high-performance elevator controllers, heat dissipation has always been a key factor affecting their performance and stability. XDCPCBA has launched a new and efficient heat dissipation design solution. During the circuit board design stage, the company uses multi-layer heat dissipation copper foil and thermal via technology to increase the heat dissipation area and improve the heat conduction efficiency. In terms of component layout, XDCPCBA directly contacts the heat dissipation chip with the heat sink, and optimizes the heat dissipation duct design to ensure that the heat can be quickly dissipated to the surrounding environment. This efficient heat dissipation design solution effectively reduces the temperature of the elevator controller during operation and improves its stability and life.

Green manufacturing and sustainable development

With the increase of environmental awareness, green manufacturing has become an important trend in the PCBA processing industry. XDCPCBA actively responds to environmental protection regulations, adopts environmentally friendly materials such as lead-free soldering and low-VOC coatings, and reduces waste emissions through process optimization. In addition, the company also promotes the development of a circular economy model and strengthens the recycling and reuse system of waste electronic products. These measures not only meet international environmental standards, but also provide customers with more environmentally friendly and sustainable PCBA solutions.

3. Innovative Practice of Elevator Controller PCBA Processing Technology

In the manufacturing process of elevator controllers, XDCPCBA has innovatively practiced and applied the above-mentioned latest PCBA processing technology. By introducing automation and intelligent technology, adopting new welding processes, applying 3D stereoscopic layout technology, and launching efficient heat dissipation design solutions, XDCPCBA has successfully improved the manufacturing efficiency and product quality of elevator controllers.

In terms of the application of automation and intelligent technology, XDCPCBA has achieved efficient and intelligent processing of elevator controller PCBA by introducing advanced automated placement machines and intelligent management systems. This not only improves production efficiency and placement accuracy, but also reduces labor costs and the impact of human factors on product quality.

In terms of the application of new welding processes, XDCPCBA has successfully applied laser welding technology to the manufacture of elevator controller PCBA. By precisely controlling welding points and reducing the impact of thermal stress on components and circuit boards, the company has effectively improved welding quality and reliability. At the same time, the optimization of lead-free welding processes also ensures the environmental protection and safety of elevator controller products.

In the application of 3D layout technology, XDCPCBA effectively saves circuit board space and improves signal transmission efficiency and system integration through measures such as three-dimensional stacking and distribution of components. This not only meets the needs of miniaturization and multifunctionality of elevator controllers, but also provides them with a more compact and efficient circuit design solution.

In terms of the introduction of efficient heat dissipation design solutions, XDCPCBA effectively reduces the temperature of the elevator controller during operation and improves its stability and life by adopting multi-layer heat dissipation copper foil and thermal via technology and optimizing the heat dissipation duct design. This provides a strong guarantee for the long-term stable operation of the elevator controller.

4. Future Prospects of Elevator Controller PCBA Processing Technology

Looking to the future, elevator controller PCBA processing technology will continue to develop in the direction of intelligence, miniaturization, high performance and greening. With the continuous development and popularization of emerging technologies such as 5G communications, the Internet of Things and artificial intelligence, elevator controllers will face more diverse and complex application scenarios and needs. This will put forward higher requirements and challenges for PCBA processing technology.

Further improvement of intelligence and automation level

With the continuous development and maturity of intelligent manufacturing technology, the elevator controller PCBA processing process will achieve a higher degree of intelligence and automation. By introducing more advanced automation equipment and intelligent management systems, enterprises can further improve production efficiency and product quality and reduce labor costs and the impact of human factors on product quality.

The continuous emergence of new materials and processes

In order to meet the requirements of elevator controllers for high performance, miniaturization and environmental protection, new materials and processes will continue to emerge and be widely used. For example, new materials and processes such as high-frequency materials, flexible circuit boards and green welding processes will provide more high-quality, efficient and environmentally friendly solutions for the manufacture of elevator controllers.

Enhancement of personalized customization and flexible production capabilities

With the increasing market demand for personalized products and the rapid changes in consumer preferences, elevator controller PCBA processing companies need to have stronger personalized customization and flexible production capabilities to quickly respond to market demand and meet customer needs. By adopting modular design, fast line change technology and digital production management systems, personalized customization and flexible production capabilities can be improved and more business opportunities and development space can be brought to enterprises.

In-depth practice of green manufacturing and sustainable development concepts

With the continuous enhancement of global environmental awareness and the increasingly stringent environmental regulations, green manufacturing and sustainable development concepts will be more deeply practiced and applied in the elevator controller PCBA processing industry. By adopting environmentally friendly materials, energy-saving and emission-reduction technologies, and recycling measures, resource conservation and environmental protection can be achieved in the production process, and a solid foundation can be laid for the sustainable development of the enterprise.

V. Conclusion

The innovation and development of elevator controllers cannot be separated from the support and promotion of PCBA processing technology. As a leading provider in the PCB industry and an innovative practitioner of elevator controller PCBA processing technology, XDCPCBA is providing more high-quality, efficient and environmentally friendly solutions for the manufacture of elevator controllers with its strong production strength, comprehensive service capabilities and spirit of continuous innovation. Looking to the future, with the continuous advancement of science and technology and the continuous changes in the market, XDCPCBA will continue to uphold the customer-centric service concept and the development concept of continuous innovation, continuously promote the advancement and development of elevator controller PCBA processing technology, and contribute more to the intelligent upgrading and sustainable development of the elevator industry.

In the manufacturing process of elevator controllers, PCBA processing technology plays a vital role. From the design and manufacturing of circuit boards to the mounting, welding of components and final testing and quality control, strict control is required to ensure the performance and stability of the product. With its professional technical strength and rich industry experience, XDCPCBA has made remarkable achievements in the field of elevator controller PCBA processing and has won wide recognition.

Looking to the future, with the continuous emergence of emerging technologies and the continuous changes in the market, the PCBA processing technology of elevator controllers will face more challenges and opportunities. XDCPCBA will continue to uphold the spirit of innovation and a pragmatic attitude, and continue to explore new technologies, new processes and new methods to promote the progress and development of PCBA processing technology for elevator controllers. At the same time, the company will also strengthen exchanges and cooperation with partners inside and outside the industry to jointly promote the intelligent upgrading and sustainable development of the elevator industry. I believe that in the near future, XDCPCBA will bring more surprises and breakthroughs to the manufacturing of elevator controllers and bring more convenient, safe and comfortable experience to people's travel life.