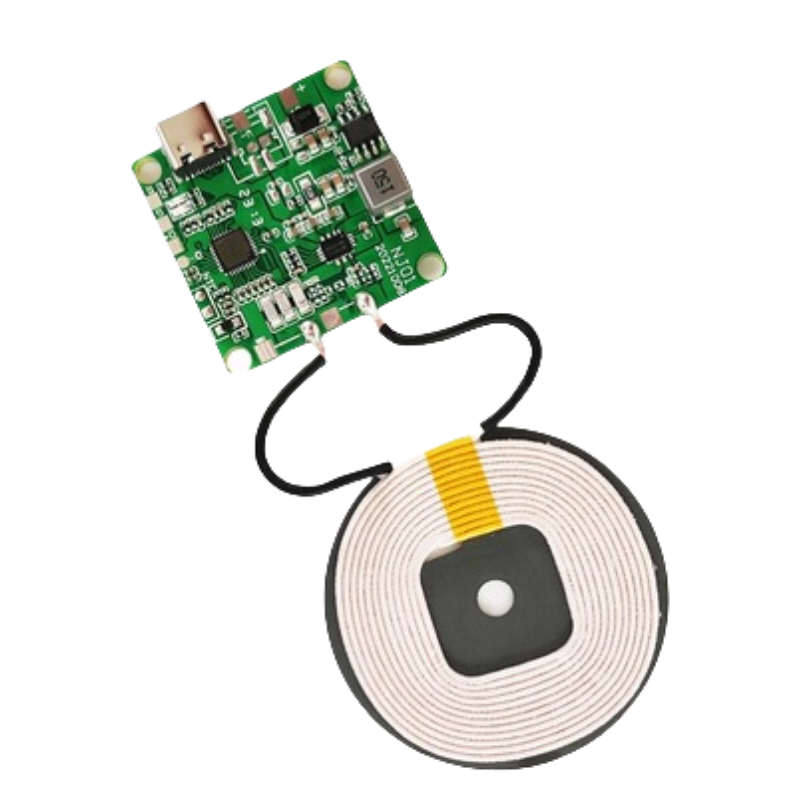

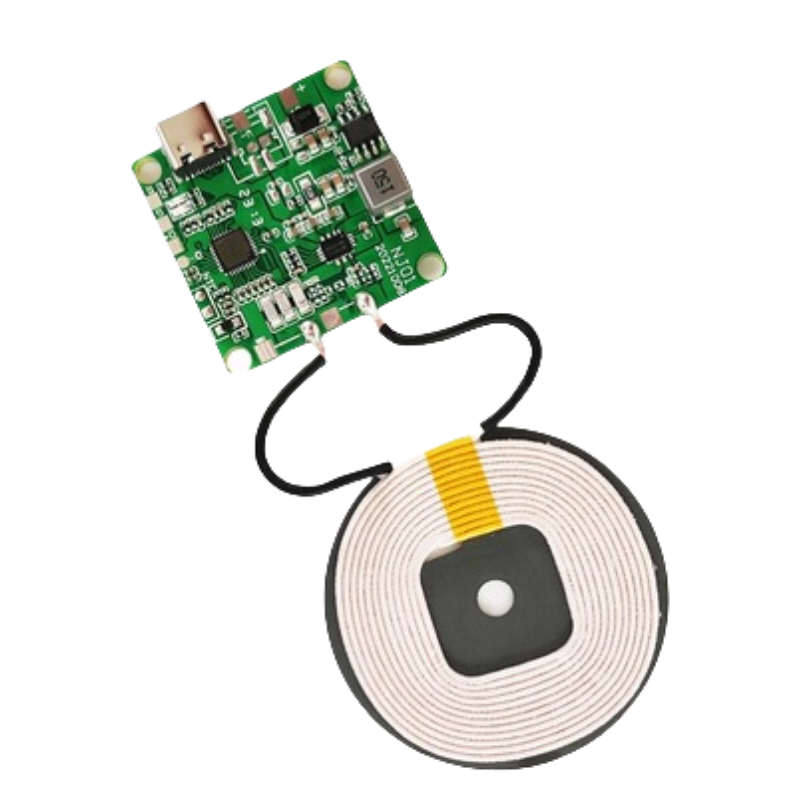

XDCPCBA's wireless charging module PCBA processing service is designed to meet the high requirements of modern consumers for wireless charging devices. With the continuous development of technology, wireless charging has become a trend, which provides users with a more convenient and efficient charging method. However, the design and production of wireless charging modules face many challenges, such as electromagnetic compatibility, heat dissipation performance, charging efficiency, etc. In order to solve these problems, XDCPCBA has carefully created this wireless charging module PCBA processing service with years of technical accumulation and rich industry experience.

In terms of PCB manufacturing, XDCPCBA has demonstrated outstanding technical strength. We use advanced production processes and high-quality raw materials, combined with high-precision laser cutting, automated electroplating and other advanced technologies to create circuit boards with high reliability and high stability. As a professional manufacturer of 2-30 layers of PCB, we can not only meet customers' needs for the number of layers, precision, performance and other aspects of the circuit board, but also customize them according to the specific needs of customers. Whether it is the size, shape, material selection, number of layers, circuit layout, etc. of the circuit board, we can provide solutions that meet customer needs. In addition, we also provide 2-6 layers of PCB free sample service to help customers quickly verify the design plan, reduce R&D costs, and accelerate the pace of product launch.

In terms of PCBA processing and assembly, XDCPCBA also has strong strength. We have a complete assembly production line and advanced SMT patch welding equipment, and the technical team has rich assembly experience and superb process skills. From the procurement of components, patch welding, plug-in welding to finished product assembly, every link is strictly controlled to ensure the excellent quality of the final product. Especially in the wireless charging module, we focus on the optimization of electromagnetic compatibility and heat dissipation performance, and use advanced materials and processes to ensure that the product maintains efficient and stable charging effect during long-term use. At the same time, we also conduct rigorous tests on the wireless charging module, including charging speed, charging efficiency, temperature control and other aspects to ensure that the product can meet the stringent standards of wireless charging equipment.

In addition to high-quality products and services, XDCPCBA also pays attention to communication and collaboration with customers. We have a professional sales team and technical support team, which can provide technical consultation and solutions to customers at any time. Whether it is early product design, mid-term production follow-up or later after-sales service, we can provide customers with all-round support and guarantee. We are committed to establishing long-term and stable cooperative relationships with customers and jointly promoting the development and innovation of the wireless charging equipment industry.

In terms of differentiated services, XDCPCBA not only provides high-quality PCBA processing services, but also focuses on providing customized solutions for customers. We are well aware that the needs of each customer are unique, so we will provide personalized PCB design and PCBA processing solutions according to the specific needs of customers. Whether it is the number of layers, size, material selection of the circuit board, or the procurement of components, patch welding, plug-in welding and other process flows, we will tailor it according to the actual needs of customers to ensure that the final product can meet the expectations and requirements of customers.

In addition, XDCPCBA also pays great attention to environmental protection and sustainable development. During the production process, we use environmentally friendly materials and energy-saving equipment to reduce the impact on the environment. At the same time, we also actively participate in various environmental protection activities and are committed to promoting the green development of the entire electronics manufacturing industry.

Looking to the future, XDCPCBA will continue to uphold the business philosophy of "quality first, customer first, innovation-driven, green development", and continuously introduce advanced technology and equipment to improve product quality and service level. We will continue to deepen the field of PCB manufacturing and provide customers with more high-quality, efficient and customized electronic manufacturing services. At the same time, we also look forward to working with more customers to jointly explore new fields and new opportunities in the wireless charging equipment industry and create a better future. Choosing XDCPCBA means choosing an innovative, reliable and trustworthy partner to jointly write a new chapter in wireless charging module PCBA processing services.