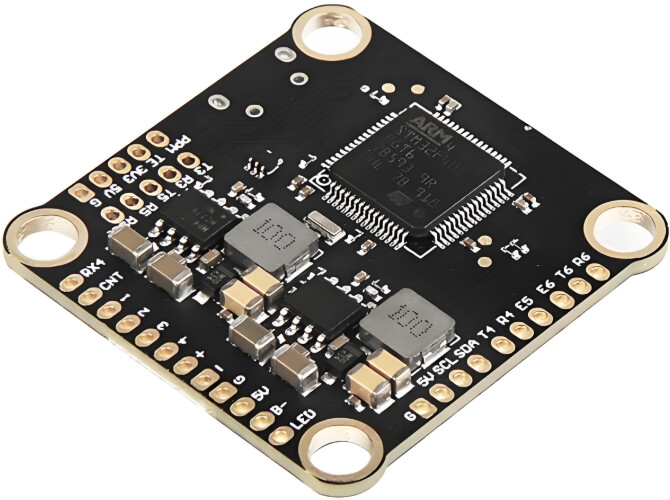

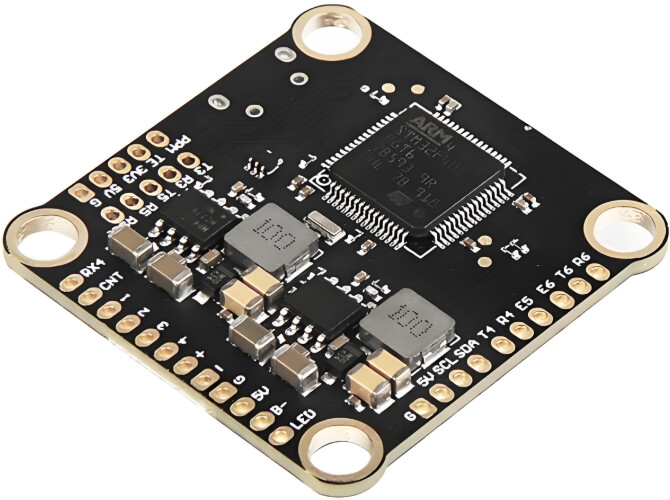

High-precision manufacturing, high-reliability assembly

Multi-layer PCB manufacturing: supports 2-layer to multi-layer circuit boards, suitable for complex drone circuit design.

Rapid prototyping: shorten the development cycle and provide you with fast prototyping services.

High-density connection: adopt advanced manufacturing technology to meet the needs of high-density spacing and tiny components.

Surface mount (SMT) and manual assembly: combine automation and manual assembly to ensure the high reliability of each soldering point.

Strict quality control

Follow aviation-grade quality standards and strictly implement ISO certification processes to ensure that each PCB undergoes multiple tests and verifications.

From raw material procurement to finished product delivery, every link is strictly controlled to ensure the high quality and reliability of the product.

Technical Specifications

Number of layers: 2 to multiple layers (supports high-density spacing)

Minimum aperture: 0.1 mm

Minimum spacing: 0.1 mm

Surface treatment: HASL, Immersion Gold, Immersion Silver, OSP, etc.

Material: FR4, High-Tg, Halogen-free, etc.

Application areas

Our custom UAV PCBs are widely used in:

UAV control systems

Navigation and communication modules

High-frequency signal transmission equipment

Avionics integration systems

UAV payload equipment

Why choose us?

Quick response: Support rapid prototyping and small batch production to shorten your development cycle.

High cost performance: Provide competitive prices while ensuring high-quality products.

Global services: Provide high-quality services to global drone manufacturers and developers.

If you need customized drone PCB solutions, please contact us now, we will provide you with professional technical support and high-quality services!