Our Product Benefits

Excellent Signal Integrity:Minimizes signal loss and improves data transmission quality, ensuring clear communications.

Advanced Thermal Management:Uses cutting-edge heat dissipation technology to maintain optimal operating temperature even at high-frequency operation.

Rugged Manufacturing:Designed with durability in mind, our PCBs withstand the rigors of daily use, ensuring long-term reliability and performance.

Industry Compliant:Manufactured to RoHS and IPC standards, ensuring a safe environment and compliance with global regulations.

Product Specifications

| Parameter | Specifications |

| Frequency Range | Supports 5G mmWave bands (24 GHz – 90 GHz) |

| Number of Layers | Up to 10 layers |

| Minimum Trace Width/Spacing | 3 mil (0.075 mm) |

| Via Diameter | 0.1 mm |

| Material | High-frequency, low-loss dielectric |

| Operating Temperature | -40°C to 125°C |

| Compliance | RoHS compliant, IPC-7351 certified |

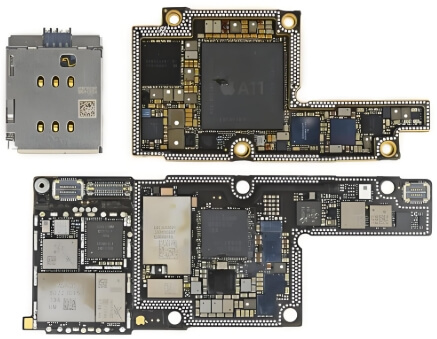

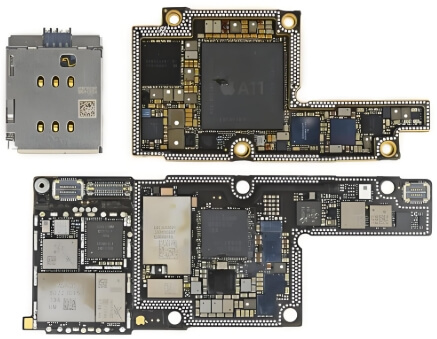

Assembly Process

1.Design

Utilizes advanced software for precise layout and design, ensuring minimal interference and optimal signal routing.

2.Manufacturing:

2.1Etching: High-precision etching to accurately define circuit paths.

2.2Drilling: State-of-the-art through-hole drilling to ensure inter-layer connectivity.

2.3Lamination: Carefully layering materials to maintain structural integrity and signal consistency.

3.Component Assembly:

3.1Surface Mount Technology (SMT): High-speed, high-precision placement of components.

3.2Through-Hole Technology (THT): Robust mounting of components that require greater mechanical strength.

3.3Hybrid Technology: Integrate SMT and THT components to meet a variety of application needs.

4.Testing and Inspection:

4.1Automated Optical Inspection (AOI): Ensure component placement accuracy.

4.2In-Circuit Test (ICT): Verify electrical connections and functionality.

4.3Functional Testing: Comprehensive testing to ensure performance under real-world conditions.

Our Services

Custom PCB Design: Tailored to specific customer requirements to ensure your vision is realized.

Rapid Prototyping: Rapidly complete prototyping to accelerate product development.

Mass Production: Scalable manufacturing to meet the needs of high-volume production.

PCB Assembly: Provide SMT, THT, and Hybrid Technology assembly services with strict quality control.

Testing and Validation: Extensive testing to ensure compliance with industry standards and customer specifications.