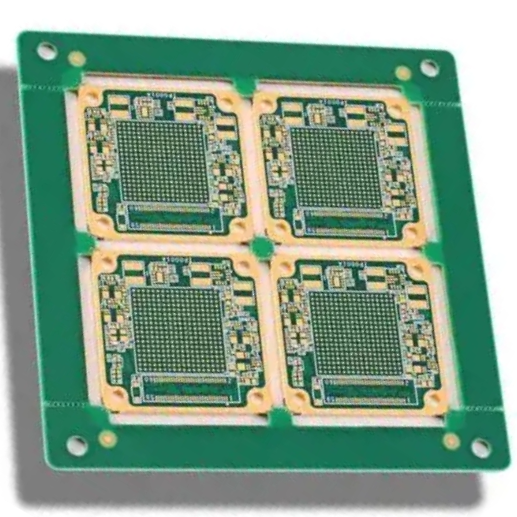

Double-sided PCB means that there are conductive patterns on both sides of the circuit board, which can effectively increase the connection density of the circuit and reduce the wiring length per unit area.

Immersion gold is a surface treatment process that usually forms a thin gold layer on the pads and contact points of the PCB to improve welding performance and anti-oxidation ability. Immersion gold treatment can provide better electrical connection and longer service life.

The immersion gold surface can effectively prevent oxidation and wear, ensure the connection stability in long-term use, and is particularly suitable for high-frequency and high-speed applications.

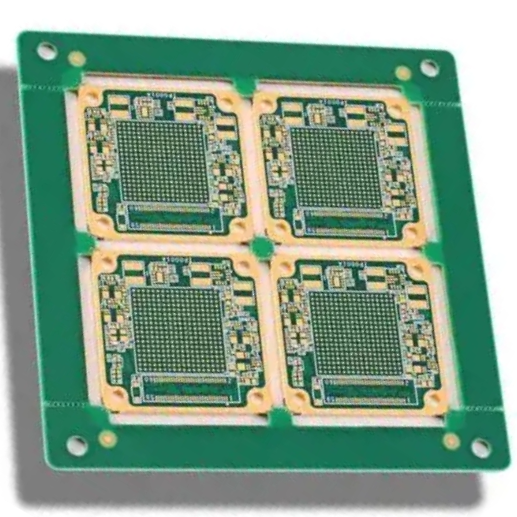

The good conductivity and wettability of the metal pad make the welding process smoother, especially suitable for the welding of SMT (surface mount technology) components.

FR-4 materials and immersion gold surface treatment can effectively reduce signal loss, improve the electrical performance of PCBs, and are suitable for high-frequency applications.

Use PCB design software to complete the circuit diagram and layout to ensure that the wiring of the double-sided circuit is reasonable and the signal

According to the design file, the FR-4 substrate is manufactured, cleaned and dried, and prepared for subsequent processing.

Etching is performed on the surface of the substrate to form the required circuit pattern, and then covered with a thick layer of copper to ensure conductive performance.

A gold layer is generated on the pads and contact points by chemical deposition to complete the gold treatment, ensuring that the welding area has good conductivity and oxidation resistance.

Electrical testing and quality inspection are carried out to ensure that the PCB meets the standard requirements before leaving the factory.